-

Building a better mousetrap: The red rifle front sight tool.

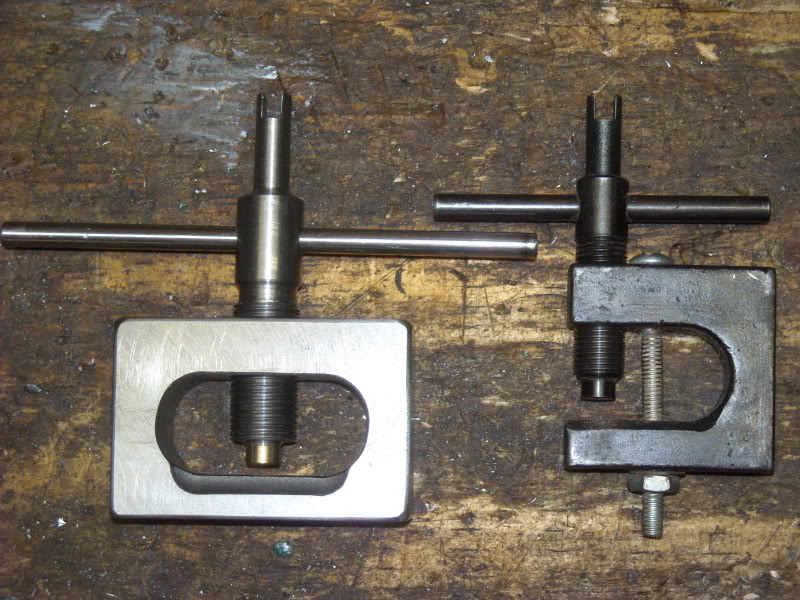

Anyone who's ever had an SKS, VZ58, etc. with the cylindrical front sight windage block has probably have on of the readily available cast metal C-clamp type front sight adjustment tools.

Do they work? Yes. Do they last? Well... sometimes and only if used on some guns. Some of those front sights are really tight! Inevitable, the cheap tools all seem to bend at the "C". The VZ58 front sights seem to be the WORST, probably there's paint in there acting like glue or something?

Anyhow, in my case, I got some extra life out of my clamp when it bent badly one day and I needed the tool right away. I modded by adding a machine screw to re-inforce the thing. It works, but it was not elegant. I made note to build something better when time permitted.

Well, this weekend time permitted.

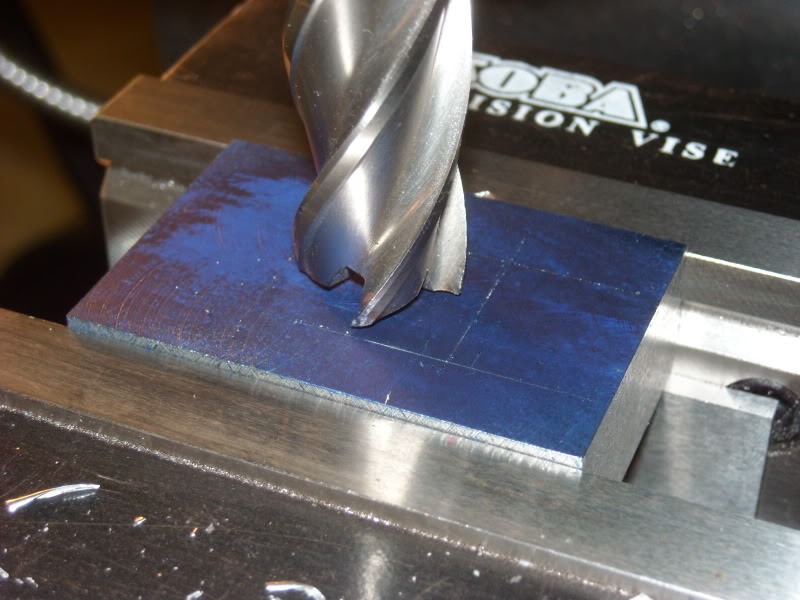

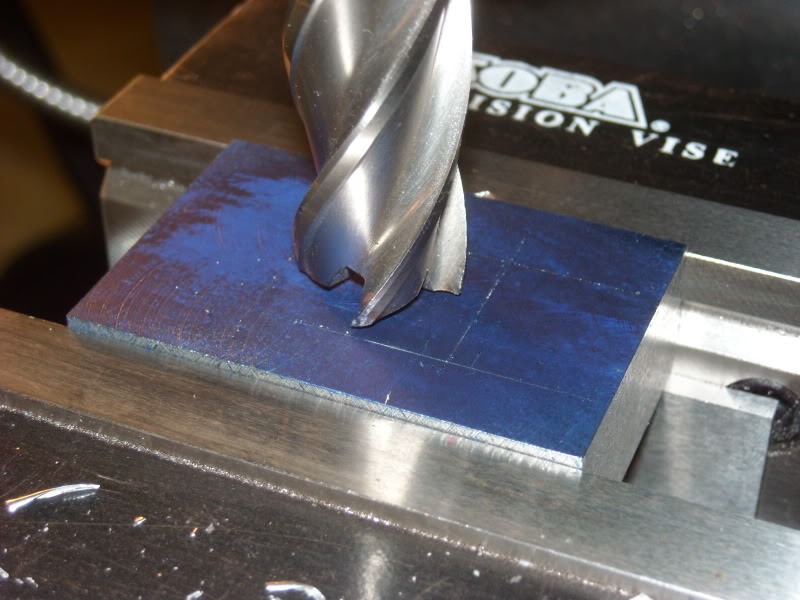

I started with a piece of 3/4" thick 1018 steel billet and some machinist's blue to do layout.

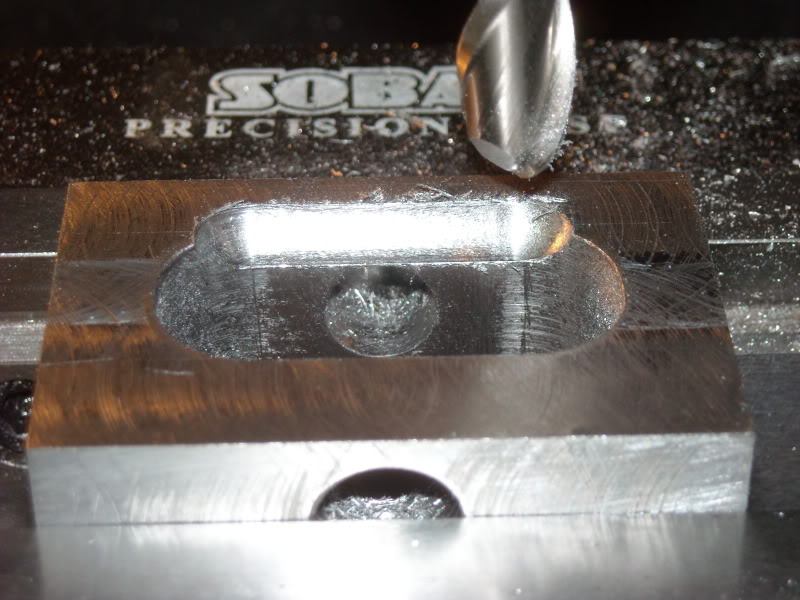

Having a knee mill and a 3-axis DRO makes jobs so much easier... let's make some chips!

Here you see the basic concept - an O-clamp design vice a C-clamp design should make things A LOT stronger. Also, the thicker billet will add rigidity.

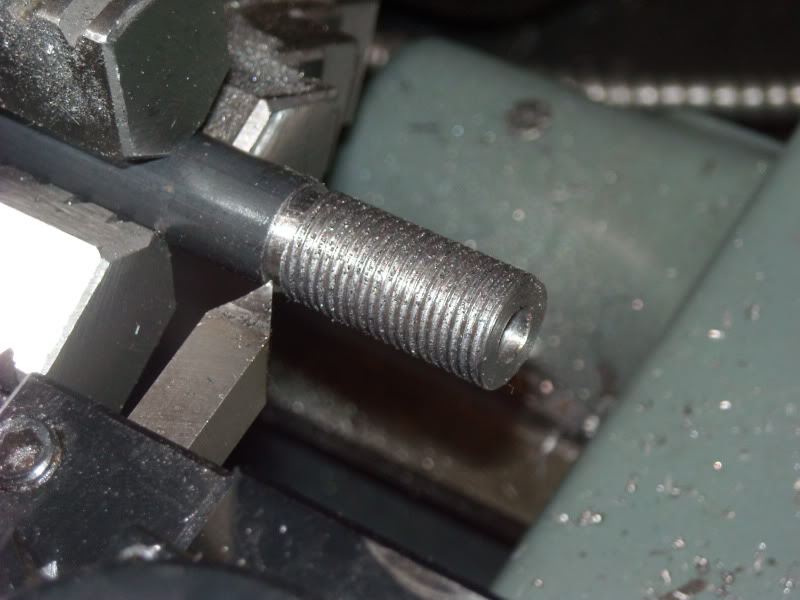

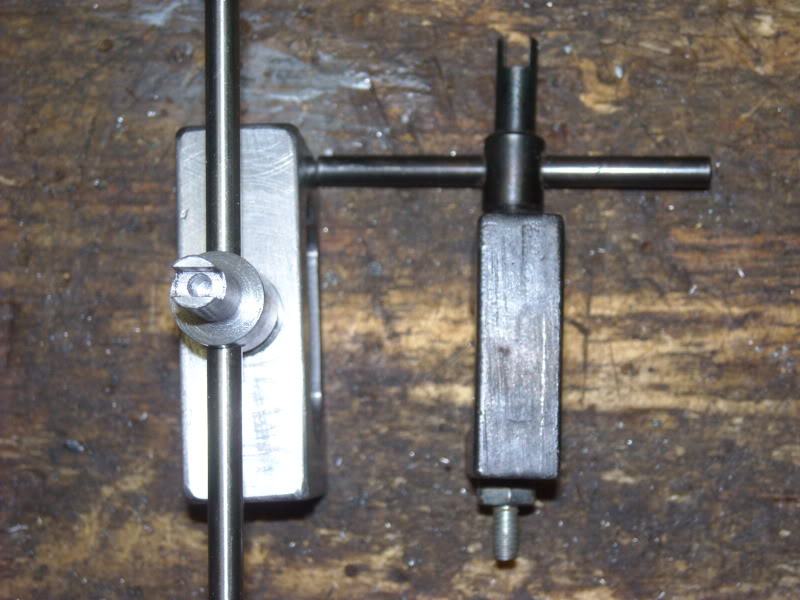

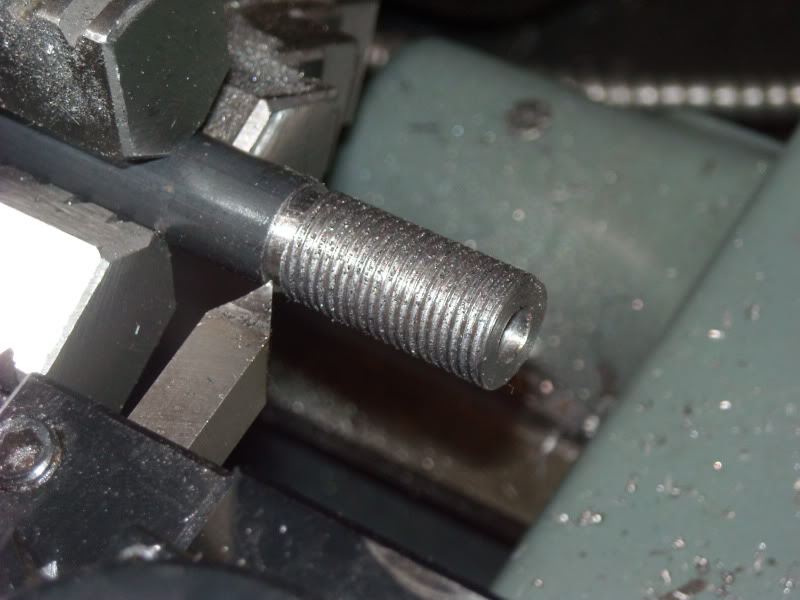

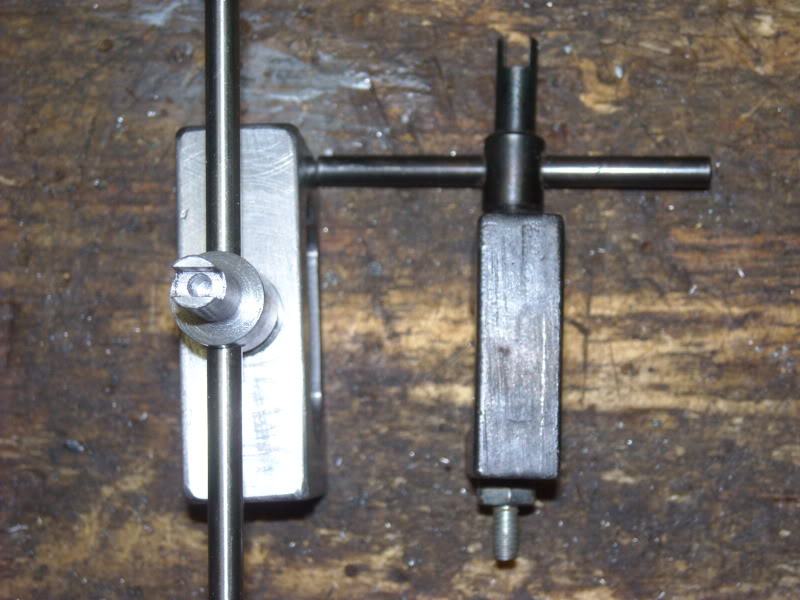

Before going further, need to make an improved and beefed up clamp screw assembly. Started with .500" hot-rolled 12L14 steel rod and hollowed out the end. This is to eventually take a piece of brass to use as the actual sight pusher - the idea being the brass won;t mar the gun's blueing like the crappy cast ones do.

Oh yeah, and a metal lathe makes this job easier. Here's we're cutting a 1/2NF20 thread.

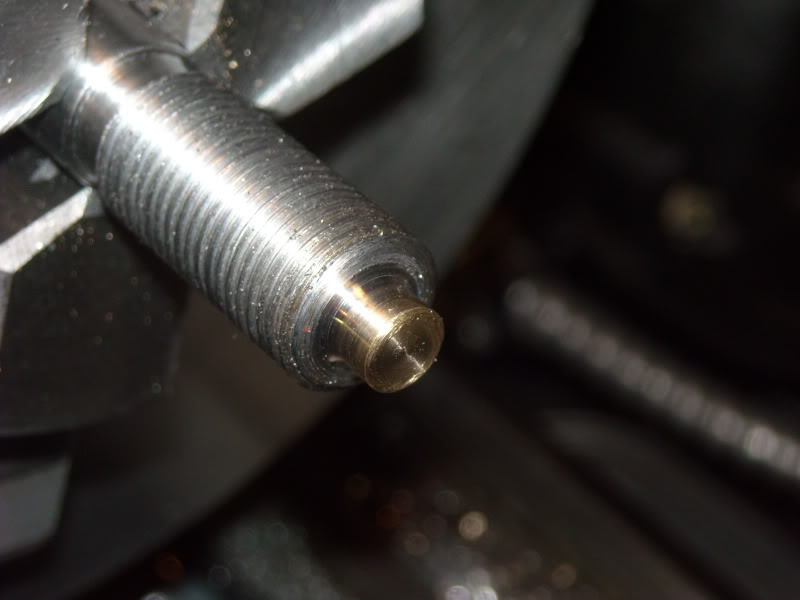

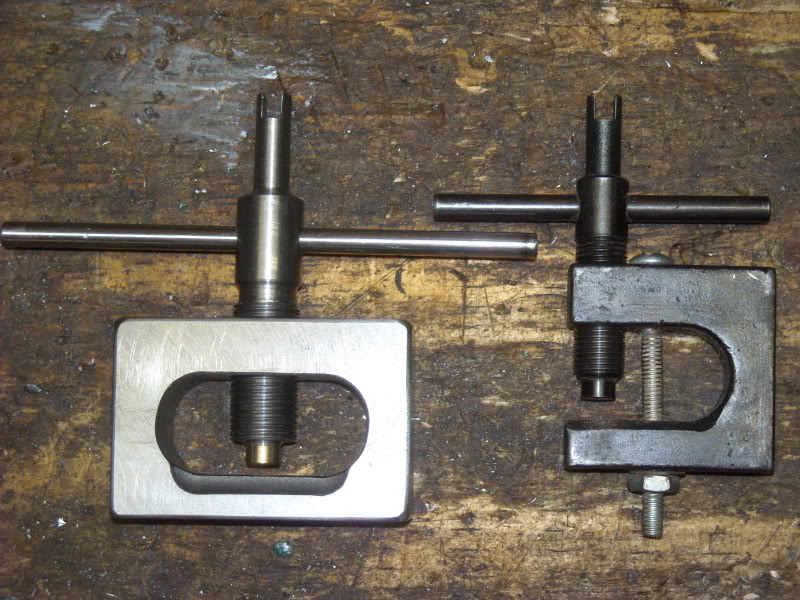

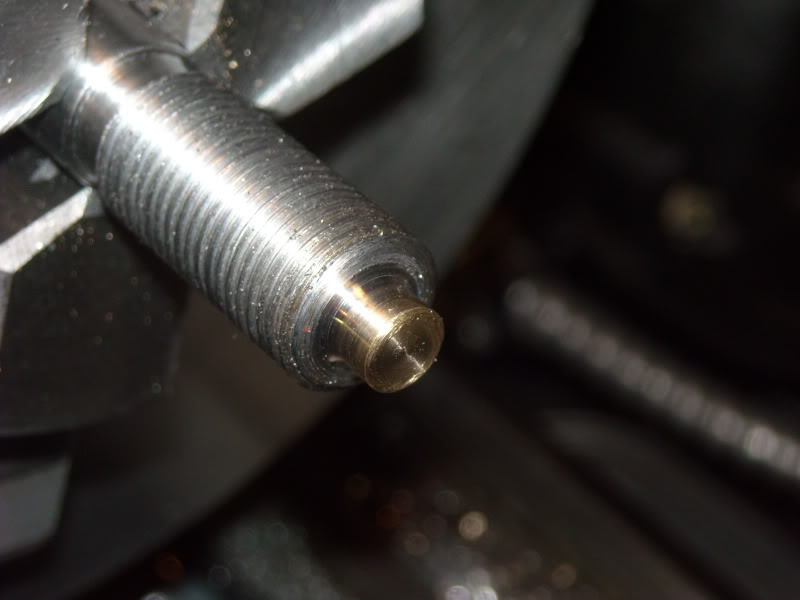

Skip ahead a bit. Got the basic clamp screw shape cut on the lathe and an appropriate piece of brass rod turned down and pressed into the hollow we made earlier. I also soft-soldered the joint and dressed the solder off in the lathe - should be nice and solid for many years to come.

This isn't really a necessary step, but the old one had it and the new one might as well be just as useful, so I turned the end of the clamp screw into a front sight tool. If you do this, you need to plan in advance and drill a deep enough hole into the end of the screw clamp assembly, on the lathe is best. Then back to the mill to cut the slot.

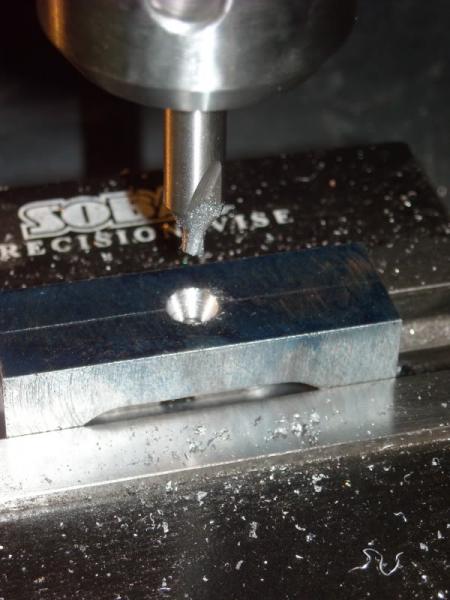

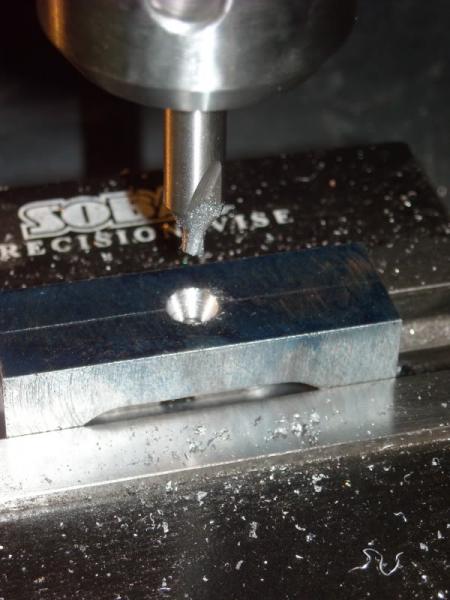

Now that we've built the clamp screw assembly, it's time to machine the hole we will tap for the clamp screw and the sight cylinder relief hole. It's ALWAYS best to start with a centre drill when you need to cut precisely aligned holes. I recommend first cutting both holes with the a smaller drill, then cutting the relief hole all the way through both ends of the clamp at once and finally drilling the 29/64" hole needed for your 1/2NF20 tap. You can use a smaller diameter thread or different pitch by the way, I went big though to make everything more robust.

Looking good...

Partially finished and starting to take shape:

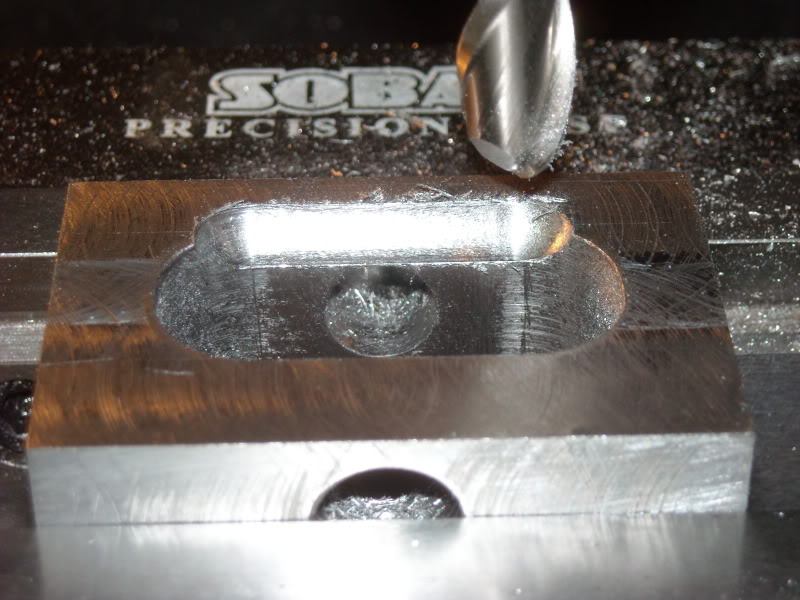

Next you need to cut reliefs for the front sight globes so that you don't bent the sight protector or mar its finish. I used a 3/8" ball cutter.

Finally, you need to break all the edges with hand files and paper, clean it up and make it look pretty, etc.

Looks much more durable than the cheaply cast original, doesn't it? Ready for a lifetime of service.

I might get around to either parking or blueing it. We shall see. It works like a charm though - new addition to the range bag!

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

Союз нерушимый республик свободных Сплотила навеки Великая Русь. Да здравствует созданный волей народов Единый, могучий Советский Союз!

-

Thank You to Claven2 For This Useful Post:

-

03-20-2010 11:38 PM

# ADS

Friends and Sponsors

-

Very, very nice - great work and excellent photos. Thanks for sharing.

Probably only cost you $10 in materials and $200 worth of labour that you donated to the cause (and you had to buy a $5000 mill)!

It's like hunting. I began hunting years ago and sold it to my wife as "free" meat. Once you factor in the start-up costs, the meat is free, but the rest is expensive. I'm now down to about $50/lb...... but the enjoyment is priceless.

Great job!

-

Thank You to Andy For This Useful Post:

-

PM

PM