-

FREE MEMBER

NO Posting or PM's Allowed

Originally Posted by

Brit plumber

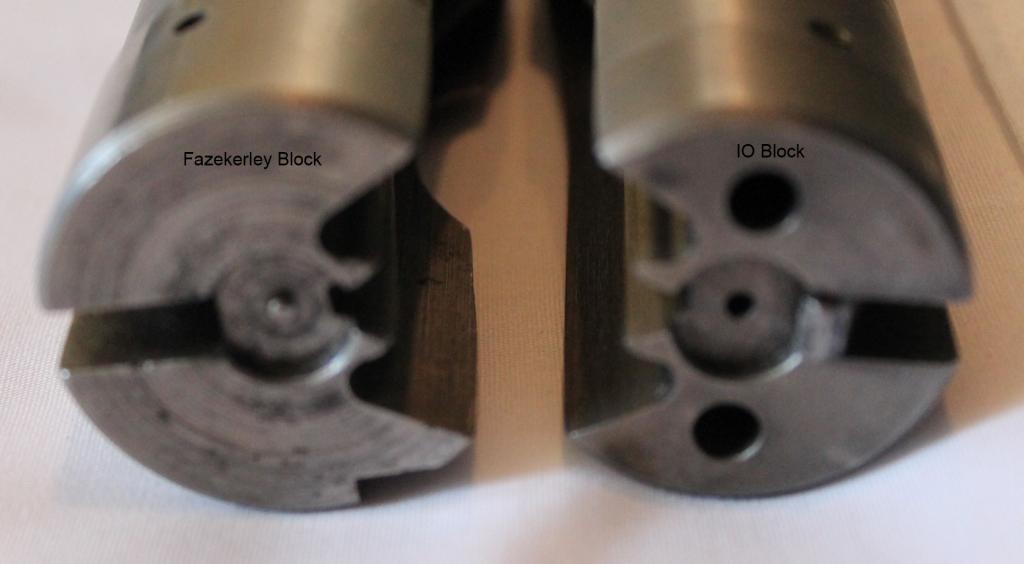

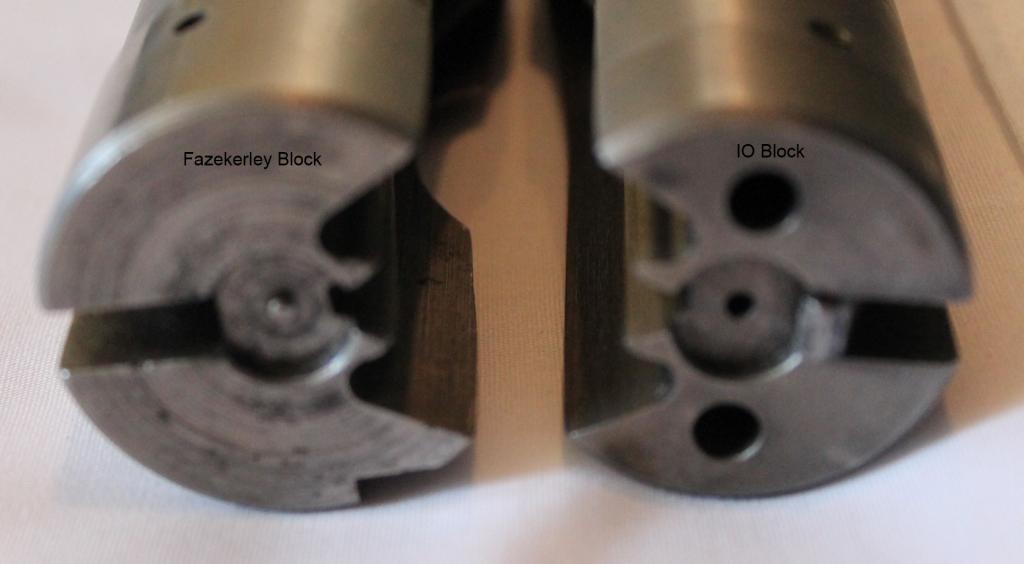

I was forgetting you are using a new Breech block so could it be the Breech block machining that isn't the same as the original in the outside edge of the machining for the feed horns? How does it compare to the original block?

Looking at the photo of where the block interferes with the ejector, it looks to be about 1/2" long so would you not have to move the safety slot back the same amount for it to clear?

Blocks look the same. Sorry for the cr@ppy photo, but you get the point. The groves are machined the same so they will ride over the magazine lips. The bolt intrudes over the ejector slot by 5/16" at best. I think milling the safety slot 5/16" farther aft on the tube would solve this problem. I'll call Jason and see what he thinks.

-

04-22-2014 02:27 PM

# ADS

Friends and Sponsors

-

FREE MEMBER

NO Posting or PM's Allowed

Spoke with Jason about the issue and sent him the images.

Last edited by 17thairborne; 04-22-2014 at 03:41 PM.

-

-

FREE MEMBER

NO Posting or PM's Allowed

Regarding the ejector/block interference:

Below is a link to a photo from another STEN builder's post: Notice how little material is left between the safety slot and the operating slot. That was my concern about milling the safety slot a bit closer to the operating slot as opposed to moving the slot aft 5/16"

I suppose in my case there's enough distance between the two that dropping it 1/16" will not make that much difference?

13 Photo by w9amr | Photobucket

-

FREE MEMBER

NO Posting or PM's Allowed

Welding (TIG) tentatively scheduled for Friday. Will post pics and details as soon as I'm done.

Looking ahead to the finish. My research indicated that the STEN Mk V was finished with a dark grey phosphate finish and then painted with the semi-gloss black paint.

I am looking at Brownell's Manganese Phosphate kit. It is my intent to DIY the process and be able to do more with the remaining materials later.

Any advice for the novice? I read many of the MILSURPS posts regarding the process.

-

Advice........ might I suggest that you save yourself the bother and get BRian at BDL to do the phosphate and paint as he has the real McCoy process and I have seen his Mk5 Sten. Just my view of course!

to do the phosphate and paint as he has the real McCoy process and I have seen his Mk5 Sten. Just my view of course!

-

-

Advisory Panel

If you do prefer to do the finish yourself, the process is quite straightforward.

I have not used Brownell's product - cross border shipping of chemicals is problematic - but a very similar product is available in Canada .

.

The carbine in the photo that I sent you was finished with Radocy brand Parkerizing process, apart from the magazine housing. It was painted. I had to sent the carbine to the RCMP for inspection, and wanted to get it in the mail, didn't have a batch of bits to park, and didn't want to get the system up and running for one piece.

The process is simplicity itself. I prepare the surfaces by blasting them with aluminum oxide grit at about 40 psi, and then immediately park them. Out of the cabinet, the parts are clean and dry. If there is any risk of residual oil or grease, soak the pieces in hot trisodium phosphate solution, rinse, and into the park. A stainless steel pot on a hot plate or bbq works fine. An enamelled roasting pan is also good. A cooking thermometer allows the temperature to be monitored. Just stew the parts until the colour is satisfactory. I do not like the idea of parking bores, and plug barrels using a threaded rod with seals, washers and nuts. Parking is much easier and safer to do than hot caustic bluing. Even then, doing it outside is not a bad idea, there are fumes. Once the desired colour has been achieved, rinse thoroughly in hot clean water. Dry and coat with oil to cure for a day. I have not applied a coating over a parked base. I do not know whether it is best to cure the park, and then remove all traces of oil, and apply the coating, or if the coating can be applied over fresh, clean park. I have only applied coated finishes to freshly blasted surfaces.

Instead of blasting, some folks use an acid etch to give a slight tooth to the surface.

The various spray coatings - some are catalysed to cure, others are baked - are easy to use, and are effective. Matte, semi-gloss and gloss blacks are available. Application may be done with an airbrush or some products come in aerosol cans. These coatings can be applied directly to clean blasted or etched surfaces, if desired.

-

Thank You to tiriaq For This Useful Post:

-

Advisory Panel

Originally Posted by

tiriaq

I have not used Brownell's product - cross border shipping of chemicals is problematic - but a very similar product is available in

Canada

Where? From whom? That's what's been holding me up here...

-

-

Advisory Panel

Go to PJ's Gun and Metal Care Products. I have had excellent results with his park. solution and hot water bluing products. Found his cold blue to be inferior.

-

-

FREE MEMBER

NO Posting or PM's Allowed

peter,

I do not doubt he will do a superb job. I am hoping to learn a few new tricks and skills through this project, and I have never parkerized before. I am also tying to keep the costs in mind to minimize total outlay by using my labor....and....yes...your expertise , which when the opportunity presents itself for a mutual meeting on either side of the pond, we will quaff a few ales of your choosing!

, which when the opportunity presents itself for a mutual meeting on either side of the pond, we will quaff a few ales of your choosing!

---------- Post added at 04:13 PM ---------- Previous post was at 04:10 PM ----------

Originally Posted by

tiriaq

If you do prefer to do the finish yourself, the process is quite straightforward.

Thanks it seems so, and Brownell has a very detailed description of the process to get the results correct. I am looking forward to trying.

-

Legacy Member

Originally Posted by

17thairborne

which when the opportunity presents itself for a mutual meeting on either side of the pond, we will quaff a few ales of your choosing!

Peter is an Armourer so unless he has turned into a xxx since leaving the Army, he wont quaff his ale, he will 'Down' his pint to the chant 10, 9, 8.....3, 2, 1 on yer 'ead!

But then again he did take a commission so it may be a glass of port, and then some burning of the mess piano or other such antics that would get the rest of us mere mortals 14 days in the glass house!

-

Register To Reply

Register To Reply

, which when the opportunity presents itself for a mutual meeting on either side of the pond, we will quaff a few ales of your choosing!

, which when the opportunity presents itself for a mutual meeting on either side of the pond, we will quaff a few ales of your choosing!