-

Legacy Member

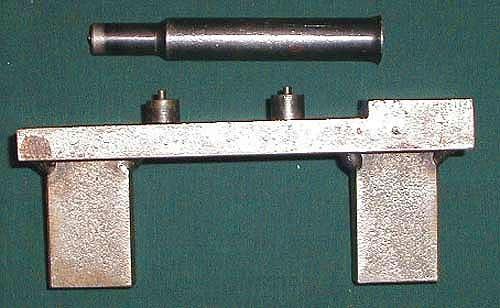

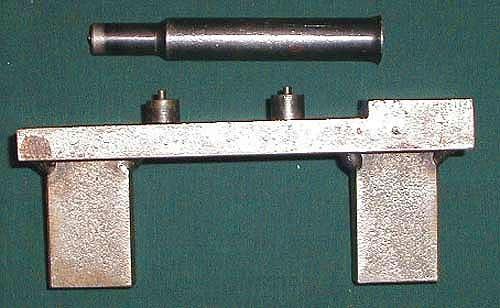

Here's the lovely tool, Peter refers too.

-

The Following 2 Members Say Thank You to nzl1a1collector For This Useful Post:

-

04-23-2014 12:31 AM

# ADS

Friends and Sponsors

-

That's the one............. Another of those tools that for some reason, could only be used properly and effectively by one person. Usually someone that was completely cack-handed at everything else!

There was also another similar tool, with a punch, that was invented to aid the tightening up of the cross piece rivets by, well....., knocking seven bells out of them! This tool worked quite well but a better method was to just carefully mig the loose crosspiece to the blade. NOT allowed of course as it would(?) upset the temper of the blade at that point but if you were quick, not too much heat and careful and didn't quench afterwards, it always seemed to be OK

Last edited by Peter Laidler; 04-23-2014 at 03:46 AM.

-

-

-

Contributing Member

I gave up on trying to build a tool. The steel rivets are simply too hard and have too long an unsupported shank going through the wood portion of the Handguard to work. So, who knows something about rivets that can point me in the right direction? The shank needs to be about 3/32" with a slightly larger rounded head if I can. I need to be able to crush it to pinch the spring to the Handguard without the shank folding sideways into itself and destroying the wood. To be honest in thinking a small pop rivet of some kind may be more practical? Does anyone here have any ideas?

-

-

What about using brass - or isn't that original? Seems to me that like most rivetting jobs, yours is a typical three handed job. One to hold the dolly/forming tool, one to hold the work in the correct place/angle and the other to tap the dolly.

Maybe you're whacking the hammer too hard. It's not ships plates you're rivetting! Better to have a zillion small taps than two great thumps. Mind you, without access to a Ross I might be barking up the entirely wrong tree!

-

-

Legacy Member

Have you tried annealing the rivets, especially if they are old rivets. And perhaps if possible try a mechanical method of forming the rivet. I've used my old heavy RECORD bench vice with a lot of success.

-

-

Contributing Member

Brass apparently wasn't original, but after the fight with these rivets I'm willing to settle for brass gladly. I thought I was being gentle, maybe not enough. The tool I built held everything fairly snugly in place, the end of the shank was down inside a 7/64" hole with a piece of small hobby sized drill bit (can't remember the size, pretty small!) set into the bottom of the hole as a center pin like the tools you guys have shown. The tip of the shank would barely dent on the pin after 5-6 taps and then the shanks would bend in the middle and gouge the wood.

Time to find some brass ones maybe.

I could try annealing them, haven't done that yet! Good idea!

-

-

Legacy Member

The rivets have a flat head. This is supposed to be on the inner side of the retaining spring.

The shaft of the rivet mates with a brass washer which is inserted down in each of the holes in the top of the handguard.

These dinky brass rivets and washers are dimensioned thusly:

Rivet

Overall length: .29" (+.02")

Body dia: .08" (-.002")

Head dia: .13" (+.01")

Head thickness: .02" (+.01")

Washer

Thickness: .04"

Diameter: .2"

Hole: .082"

The screws for retaining the end-cap on early front handguards are dimensioned as follows:

Mild steel, (blued)

Overall length: Max-.22", Min-.215"

Shank length: Max-.165", Min-.16"

Head dia.: Max-.197", Min-.195"

Slot width: .024" +/-.002"

Slot depth: .03"

Thread dia.: Max-.096" Min-.095"

Pitch: 56TPI (Enfield Std, RH)

Not all that surprising that brass rivets became the preferred option for attaching the cap to the front handguard.

-

-

Maybe you should counter-bore the rivet shaft so that you simply need to use a centre punch to spread the end just sufficient to retain the cap. As you will see on the No4 handguard rivets.

There was very probably a foot-operated load limited press at the factories. We had a similar thing in the old sailmakers shops - later called the textile shop and later still, the equipment repairers section for rivetting and putting those eyelet thinggies (they were always called teddy-bears axxholes among the blokes for some strange reason) for ropes and laces etc etc in canvas and tentage stuff. Do the big workshops still have a semi-trade of 'equipment repairers' now Skippy?

-

-

-

PM

PM