-

This is a nice project to watch.

-

-

10-03-2010 11:14 PM

# ADS

Friends and Sponsors

-

-

The Following 2 Members Say Thank You to Claven2 For This Useful Post:

-

-

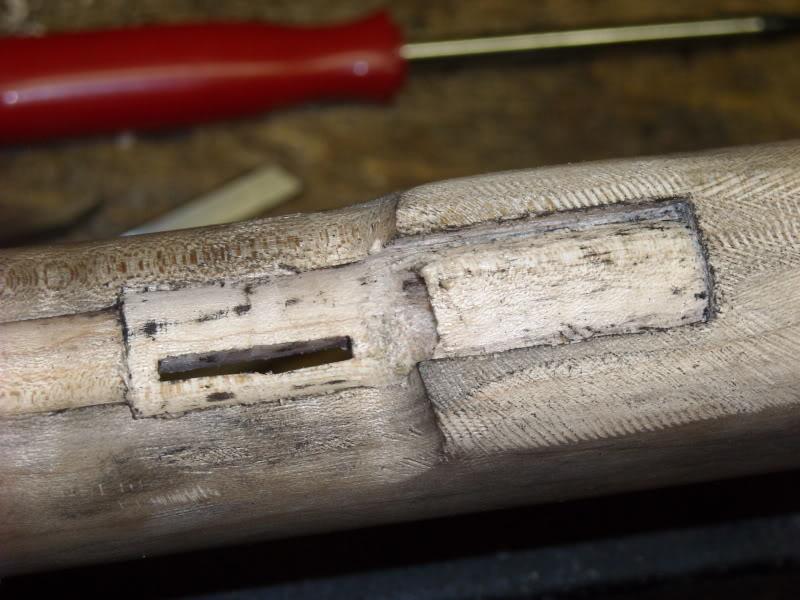

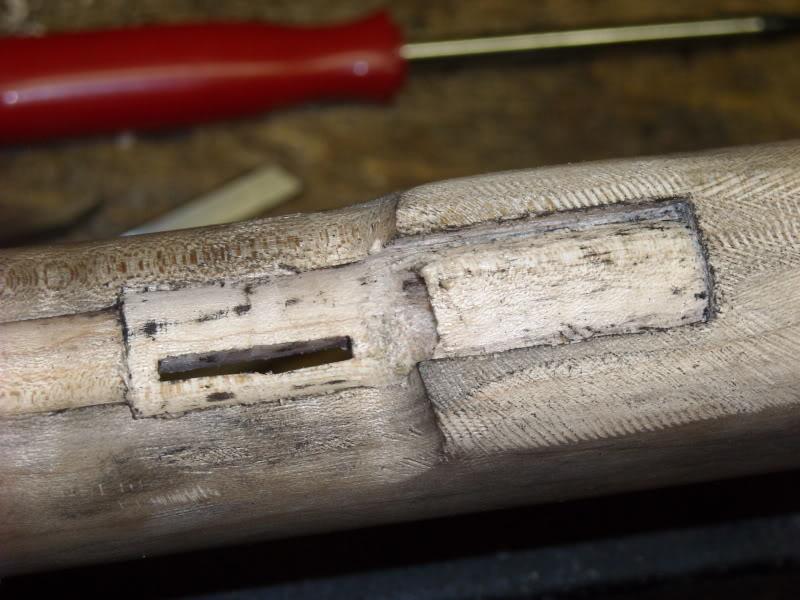

ok, well next I decided to inlet the rearmost ramrod pipe. There are three ramrod pipes on this type rifle and the rearmost is by far the most difficult to inlet (so you start with it - lol). It's also the easiest to locate for obvious reasons. See the photo, there is a step in the forestock where it goes.

Now there is the easy way (i.e. lazy and improper way) to inlet the rear ramrod pipe and then there is the right way. The right way is a lot harder to do but has the advantage of being right - lol. The easy way is to simply mill or chisel out the area under the pipe flange, leaving it unsupported by the wood of the stock. The right way is to carefully inlet it so wood remains under the flange to support it. You do this by outlining it with pencil, chiselling smaller than the pencil lines and ultimately by switching to inletting black until you can inset a length of ramrod dowel.

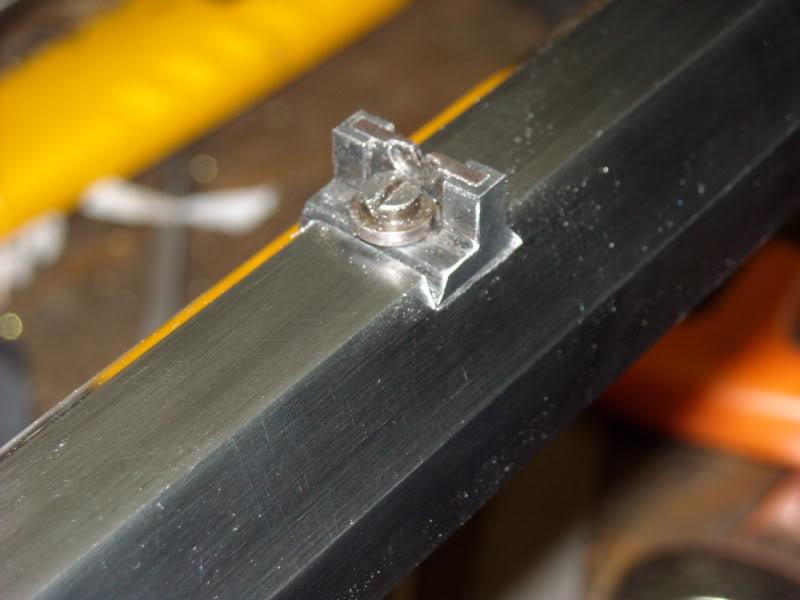

There is also a tab on the bottom of the pipe to allow you to pin it in place. I inlet these by drilling a series of under-width holes and then filing them into a slot.

You will notice the forestock is too big in this area and you will have to rasp or plane the stock down so it blends well with the ramrod pipe as you progress and don;t forget inletting black - your best friend! Also, use a small round file to slightly bevel the entrance to the stock's ramrod channel hole.

And finally, you will be done.

See how nice and proper that inletting looks compared to if I had just milled the wood away under the pipe flange? Before you pin it (later as I will do them all at the same time in the mill later on), make sure one last time that the ramrod will go through all three ramrods without binding - this last one is the most finicky - by far.

Now the next step now that the rear ramrod pipe is located is to use it to dimension off the drawing and mark (in pencil) the location of the three barrel tenons and cut the dovetails into the barrel to hold them. These are on the bottom flat. You always install the one back at the tang first and work your way forward.

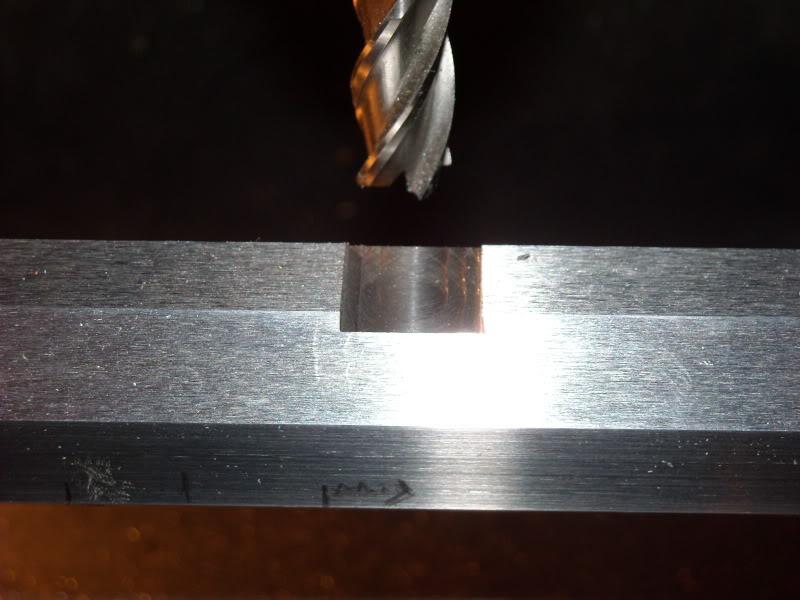

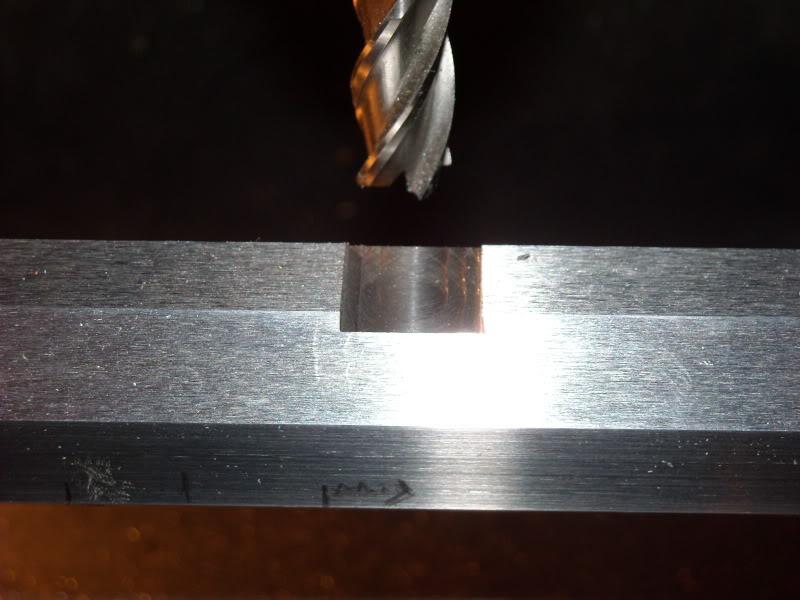

There are LOTS of ways to install these that will work, but if you have the right gear (a large enough milling machine) - this is the BEST way to do it. As I said, mark the locations in pencil. The exact position of the tenons doesn't need to be precise, but you want them to looks uniformly distant from where you will be mounting ramrod pipes. It also helps if the tenons are more or less equidistant from each other. Mount the barrel with the bottom flat facing up. I use a .375" end mills to make starter cuts and then measure the TOP of the tenon dovetails at the tenon. I subtract 10 thou and this becomes the width of my cuts. Each tenon is hand made and you need to measure each one individually and mate it to a dovetail cut. They are NOT INTERCHANGEABLE. Measure twice and cut once.

Once all three dovetails are roughed out by and end mill you COULD use a dovetail end mill, but in my case the tenons themselves are not that uniform and the sides aren't very parallel, so I'm cutting the dovetail angles with a file. Here is where a home-made tool REALLY comes in handy. I took an equilateral triangle file and un a large grinding wheel I ground one flat smooth so it won't cut. Place the smooth face against the bottom of the dovetail rough-out and file your dovetail relief angles - the file won't cut down, only laterally to make a nice dovetail and you can control the angle to match the tenons TOTW sent you.

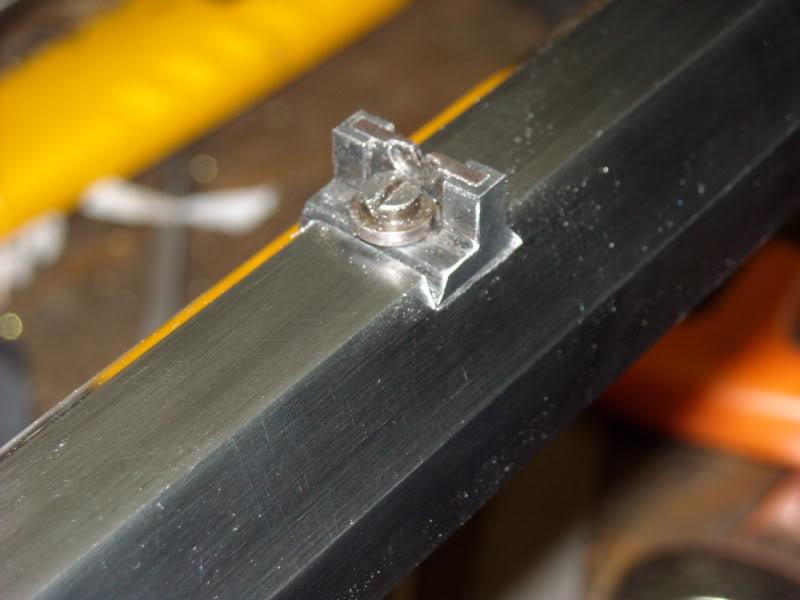

Do not overdo the filing. While the dovetail is still slightly too small, choose the smallest side and start it in with a small jeweller's hammer, then use a brass punch and a larger ballpeen to beat it in. It should be VERY hard to beat in. I like it if the barrel actually shaves a little material off the tenon itself - then you know you have a wickedly tight fit. You never will remove these tenons again, so get 'em in there tight.

Now because we don't want to booger up our inletting all sloppy-like, we file the sides of the tenon and the top of it os that it is seamless with the contours of the barrel flats. Before filing, I take a small punch and push the burred edges of the barrel's dovetail down tight to the tenon's top edge with a few good hammer smacks (the dovetail top edges expand from beating in the tenon). when done, the tenon should almost look like it grew there. Next we will inlet this one into the stock before we install the next tenon.

Союз нерушимый республик свободных Сплотила навеки Великая Русь. Да здравствует созданный волей народов Единый, могучий Советский Союз!

-

The Following 3 Members Say Thank You to Claven2 For This Useful Post:

-

Is "inletting black" something you can buy at a specialized wood working shop, or something you make up?

-

-

brownells and TOTW sell it, among others. It's a sold product like shoe polish except a lot more viscous (wet). It goes on like paint but doesn't dry like paint does.

This is the stuff I use. A little goes a long way.

http://www.trackofthewolf.com/catego...um=INLET-BLACK

Союз нерушимый республик свободных Сплотила навеки Великая Русь. Да здравствует созданный волей народов Единый, могучий Советский Союз!

-

Thank You to Claven2 For This Useful Post:

-

ok, well not much progress in the last few days as a couple things have come up, firstly I got the flu and secondly I got two vintge BP guns in that need restoration and preservation before I can get back to this project, so likely this will be on hold for a couple weeks.

Nevertheless, I did inlet the first tenon and dovetailed in the second tenon to the barrel. When inletting the first tenon (closest to the breech) you dap some inletting black on it and carefully insert the barrel in line with the stock until the black transfers. I use a very small drill and drill out a line of narrow holes then use a tiny file to elongate them into a slot.

the tenons should be about 1/2" to 1" behind where the ramrod slots will be positioned os that there is meat between them - this will lower the chance of lateral stock splits over time.

More to follow.

Союз нерушимый республик свободных Сплотила навеки Великая Русь. Да здравствует созданный волей народов Единый, могучий Советский Союз!

-

-

FREE MEMBER

NO Posting or PM's Allowed

Claven,

I have done some restoration work on some pretty beat up rifles... almost a "kit" rifle in nature based on the parts that I got. Anyway, I wish to think you for the step by step method. From what work I have done, I will attest to the difficulty of doing a good job. I appreciate the time and effort. Looking forward to more!

-

Well, sorry for taking so long since my last post. I've actually done a bit of work on this gun here and there over the last few weeks, but with the holidays, etc., progress has been very slow. The lock showed up about 3 weeks ago as well. It's mostly rough cast with machining only on the areas necessary to assemble it. It will need a lot of finishing work, but will be nicely serviceable.

I also inletted the rest of the ramrod pipes, I'll post photos of those later, but for now here is the barrel sight work I wanted to do before fixing the barrel to the stock.

The barrel dovetails were cut on the mill as stright end-mill cuts and hand-fitted with the above safe-edge triangular file.

The rear sight is off an old anschutz rifle that I milled narrower. Not period correct, but it more or less looks the part and is elevation adjustable, though discreetly.

The L&R lock:

Союз нерушимый республик свободных Сплотила навеки Великая Русь. Да здравствует созданный волей народов Единый, могучий Советский Союз!

-

Thank You to Claven2 For This Useful Post:

-

-

-

-

The Following 3 Members Say Thank You to Claven2 For This Useful Post:

PM

PM