-

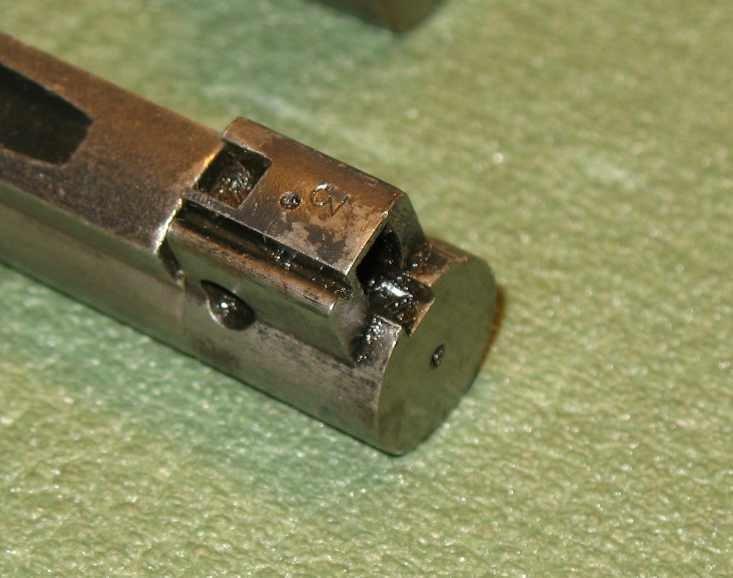

As I understand it, the Gauge bolt was ground and then calibrated to the EXACT spec. No plus or minus.., it was exact. The hardening was also extremely hard too so DON'T use one in your rifle. If I remember correctly, the channel down the top locking cam groove was hollow, right through on the No4 gauge bolt so that the standard and the gauge could never be mistaken. Can you confirm this DRP?

We also had similar breech blocks for the BESA, Bren and Vickers plus the Vickers lock parts

-

Thank You to Peter Laidler For This Useful Post:

-

06-19-2011 11:25 AM

# ADS

Friends and Sponsors

-

Advisory Panel

-

Thank You to Thunderbox For This Useful Post:

-

-

Advisory Panel

Thankyou Thunderbox and Peter!

Would it be possible to combine the two posts into an MKL entry on the topic? It would be very handy to be able to reference it to help persuade potential reactivators of DP rifles that there is more to headspace than the length of the bolt head,

entry on the topic? It would be very handy to be able to reference it to help persuade potential reactivators of DP rifles that there is more to headspace than the length of the bolt head,

-

-

From Peter Laidler 's post: "As I understand it, the Gauge bolt was ground and then calibrated to the EXACT spec. No plus or minus.., it was exact."

's post: "As I understand it, the Gauge bolt was ground and then calibrated to the EXACT spec. No plus or minus.., it was exact."

One would expect that there were at least three gaging bolts- One of maximum allowable size, one of minimum size to check NEW manfactured action bodies for proper clearance, and one that was used at the shop/overhaul level to check for maximum allowable wear- "field gage". (Probably at least one more for the FTR program, which Captain Laidler notes was held to 80% of "new" remaining service life.)

Gaging bolts themselves WOULD have allowable tolenaces, but held to a maximum of 1/10 of the production tolerance- probably closer. (I.e., if the mfg. tolerance of a certain datum was 0.002", then the worst a gage tolerance could be is 0.0002". And the tooling to check the gage ought to be held to 0.00002"!!! At some point, this requirement can no longer be met, but today it's at the atomic level...)

Last edited by jmoore; 06-20-2011 at 02:47 AM.

-

-

Got that and the reasons JM but in service we only had one bolt. Kept by the examiner in an oily tray with its certificate of calibration after being calibrated annually. It doesn't look like the long locking shoulder was hollowed right through either. Ours were all silver too, just like the SMLE bolt shown by thonderbox.

The trouble with this now is that every would be expert will want an inspectors gauge bolt!

-

-

Advisory Panel

Got that and the reasons JM but in service we only had one bolt. Kept by the examiner in an oily tray with its certificate of calibration after being calibrated annually. It doesn't look like the long locking shoulder was hollowed right through either. Ours were all silver too, just like the SMLE bolt shown by thonderbox.

The trouble with this now is that every would be expert will want an inspectors gauge bolt!

Nah, bugger them , just me!

It would be safe to assume that such an animal only existed in small numbers- possibly two only per unit which had cause to draw the gauge. Would I be right in saying the only unit(S) with such an entitlement would be highest repair before factory, and the factory themselves? Here in Aus that would probably mean (on today's system) there would be four in the country, maybe five. Perhaps there were more in Great Britain .... They would be very expensive to manufacture/ replace, and requiring annual calibration makes them NOT a desirable item to have if you don't need one.

.... They would be very expensive to manufacture/ replace, and requiring annual calibration makes them NOT a desirable item to have if you don't need one.

End result, Thunderbox, I'd think you can safely file yours behind the budgies teeth with regards to rarity.

-

-

"inspectors gauge bolt"- you're right! there would only likely be one of those available (outside the OEMs or FTR facilities). And probably only one available per shop unless it was big.

So, likely VERY few survive.

Hmmm....Maybe a rental service, like the chamber reamer rental guys? But a HUGE deposit required- refundable upon return and inspection.

-

-

These gages photo-ed above would be JUST for checking the condition of the locking surfaces, yes? It's not a multi-function gage, or, if it IS, what other features does it check, exactly?

ETA: Oops! Shoulda re-read Post #6 first:

Originally posted by Peter Laidler :

:

"This gauge bolt also dictated wear in the boltway. For example, the smaller left locking lug MUST clear the nose of the sear when loading and unloading. If it does foul, then the gauge bolt is used to verify that the body is worn and not the new bolt. This test should be carried out with the bolt lightly pressed down towards the sear nose to give an accurate assessment of the condition of the body. Obviously, it could also be used as a gauge to test other worn bolts too but in those cases, we had the 'inspection standards' specifications to refer to."

ETA2:

Back to my original thought:

Thinking about another similar thread where the radial play of the bolt seems excessive (i.e. "sloppy"). Would not a gage pin of the appropriate diameter be suitable for checking the "slop"? Pretty cheap to check in this case, as most tooling supply houses will sell gage pins individually- just need the maximum allowable diameter and possibly the allowable distance the pin can slide into the body as it seems most wear would be at the rear of the bolt raceway.

Last edited by jmoore; 06-20-2011 at 07:48 AM.

-

PM

PM