-

Legacy Member

Monk, just a side note if your brass has the what I call " ring of death" like Parashooters picture it's already to late to reload that brass. The next firing you will have case head separation. To avoid use the O ring trick with NEW brass only.

-

-

03-19-2013 07:23 AM

# ADS

Friends and Sponsors

-

Advisory Panel

-

The Following 4 Members Say Thank You to Parashooter For This Useful Post:

-

-

Legacy Member

A cost efficient way to neck size is to use a Redding Type S neck bushing sizer die for the .308 Win. This short fat die will size many different cases with the proper bushing. If you go to the trouble you can also use the bushing with a neck expander ball though I don't bother. The last time I counted there were about 40 different rounds that I could size with this one die including the .303 Brit.

I think 338 is the largest caliber the bushings are made for that will work and any case from a .30/06 down to a .22-250 should resize.

-

Thank You to ireload2 For This Useful Post:

-

Legacy Member

Many thanks to all for a interesting and informative thread. A real help.

Cheers

-

-

Legacy Member

Rounds fired in my no.4 will not fit in my no.1 so I have to keep my brass separate. I neck size my .303 brass also.

-

-

FREE MEMBER

NO Posting or PM's Allowed

I have three .303 British caliber rifles; a Lee Enfield No.4 Mk.I, a Martini-Metford ACIII, & a Ross Mk.II***. I keep a separate batch of cases for each rifle, only neck sizing the brass in an RCBS .303 British Neck-Size die, but I find I even have to back it off about 1/2 a turn when sizing the cases fired in the Ross due to its 'round-shouldered' chamber.

caliber rifles; a Lee Enfield No.4 Mk.I, a Martini-Metford ACIII, & a Ross Mk.II***. I keep a separate batch of cases for each rifle, only neck sizing the brass in an RCBS .303 British Neck-Size die, but I find I even have to back it off about 1/2 a turn when sizing the cases fired in the Ross due to its 'round-shouldered' chamber.

-

FREE MEMBER

NO Posting or PM's Allowed

I am new to reloading for the British Enfields so bear with me. It appears the obvious cause of the brass stretching and the accompanying head separations is excessive headspace. I understand the Enfields have generous chambers for "battlefield clearance". Could this problem not be cured by replacing the bolt head? If not, when reloading for a max spec. chamber, I use the following procedure. When using new brass, expand the case neck to either 8mm, or .35 caliber. Resize in the .303 neck sizing die until the case is a crush fit in the chamber, and reload the cases as usual. Upon firing the body of the case will expand to the oversize chamber without stretching the brass. Thereafter, you will only need to neck size your cases.[COLOR="black"][COLOR="black"]

Enfields so bear with me. It appears the obvious cause of the brass stretching and the accompanying head separations is excessive headspace. I understand the Enfields have generous chambers for "battlefield clearance". Could this problem not be cured by replacing the bolt head? If not, when reloading for a max spec. chamber, I use the following procedure. When using new brass, expand the case neck to either 8mm, or .35 caliber. Resize in the .303 neck sizing die until the case is a crush fit in the chamber, and reload the cases as usual. Upon firing the body of the case will expand to the oversize chamber without stretching the brass. Thereafter, you will only need to neck size your cases.[COLOR="black"][COLOR="black"]

---------- Post added at 02:34 PM ---------- Previous post was at 02:31 PM ----------

Originally Posted by

enfield303t

I always put a stip of green masking tap on the lid of the powder dispenser and write on it the powder I have been using. Comes in handy if you don't empty it when you are done and get back to reloading a few days or weeks later.

I use an index card that I insert inside the powder measure so that it is visible through the measure wall. On the card, I write the powder, the charge, and the date with a Sharpie, or other marker. Just another method of jogging the memories of those of us who have been pulling on a RL press for a few decades.

-

Advisory Panel

Originally Posted by

Sawfish

It appears the obvious cause of the brass stretching and the accompanying head separations is excessive headspace.

I am really not sure that this usual explanation is sufficient. My experience is that the before/after cases in my Enfields look just like those in Parashooter's excellent series of photos. The first time I saw this, in the "armory mint" No.1 Mk5 (how about that for the first Enfield?) it looked so extreme that I wondered if the rifle had been rechambered to .303 Epps or some other exotic wildcat.

This almost grotesque difference in the shoulder position, coupled with the space in the chamber, must surely mean that not only does the body of the case expand (as can be seen by the reflection in the transition from base web to case body) but, while this is happening, the body/sidewall of the case is also being stretched forwards as the shoulder is forced up to the shoulder in the chamber. By the time (and even if it happens in microseconds, it is still a certain time) the shoulder finally stops, it has moved forwards by a much larger amount than that permitted by any head clearance between the case and rim.

The usual explanation for the bright line is that when the case has expanded to grip the walls of the chamber, the base is then driven back, and this stretches the case to produce the hazardous bright-line, indicating an imminent failure.

While this is certainly true, I suggest that it is not the only cause, but a second stage that comes into play after the sidewall-stretch effect described above. This double-stretch would explain why Lee Enfields appear to be susceptible to producing a cartridge head separation with a head clearance that is less than on two rifles I measured and tested with a head clearance of in one case 40 thou (an Arisaka with Norma cases) and in the other case more than 50 thou (a Bubba-ed 1903-A3). In fact, it seems that Bubba had managed to set the barrel of the 1903 one turn forwards, so the cases were being held by the extractor! The Springfield produced the ominous bright lines, the Arisaka just produced fat cases, no bright lines.

with Norma cases) and in the other case more than 50 thou (a Bubba-ed 1903-A3). In fact, it seems that Bubba had managed to set the barrel of the 1903 one turn forwards, so the cases were being held by the extractor! The Springfield produced the ominous bright lines, the Arisaka just produced fat cases, no bright lines.

Summarizing, the trouble is exacerbated by new cases made to CIP/SAAMI standards fired in rifles that were probably never made to those standards, standards derived after most of those rifles were made! And I suspect that modern manufacturers form the cases to CIP minus a production tolerance, so that no-one can possibly claim that his rifle was damaged by an oversized case.

My conclusion may not be obvious, but it is this: rimmed cases suffer badly if the shoulder is set way short of the shoulder in the chamber, because the forward movement of the cartridge base when it is struck is limited to that allowed by the head clearance of the rim. In other word, the stress is trying to tear the body off the base before the case shoulder has moved up to touch the chamber shoulder.

But in the same situation, rimless cases with a short length to the shoulder can move forwards as far as the extractor permits. This may be far larger than the movement permitted even in an on-the limit Enfield (see the examples above) but actually reduces the first-stage stress on the case!

How much the extractor actually limits the travel will depend on the individual rifle, and a whole sackful of headspace gauges will not help much in recognizing or curing the problem. The only cure is to use cases that fit the rifle. Which, for reloading, means necksizing cases to leave the shoulder untouched after first firing, for bolt-action rifles, or barely touched (for SLRs).

P.S. For new readers not familiar with the term head clearance: it is the end play of a real cartridge in the rifle under investigation. And rim thicknesses can also vary! So bin those gauges and check your rifles with the cases you are going to use. And check again if you change to a different case manufacturer.

I shall now retire to the cellar and await the incoming barrage of (hopefully) productive comments!

Last edited by Patrick Chadwick; 05-31-2013 at 07:28 PM.

-

-

Legacy Member

Patrick, I agree with your assessment I think,

Head space is the gap between the head of the case and the bolt face. Whatever the cause ie rim thickness,stretched receiver of excessive gap can be rectified by #1 longer bolt head or #2 forcing the rim against the bolt face. Since a longer bolt head really isn't a option on a #1 mk3 I use a rubber washer to facilitate #2.

In short an excessive gap between rim/bolt face is the main cause of incipient case head separation on the Enfield IMHO...

-

-

Advisory Panel

Incoming!

Originally Posted by

Patrick Chadwick

. . .the body/sidewall of the case is also being stretched forwards as the shoulder is forced up to the shoulder in the chamber. By the time (and even if it happens in microseconds, it is still a certain time) the shoulder finally stops, it has moved forwards by a much larger amount than that permitted by any head clearance between the case and rim.

The usual explanation for the bright line is that when the case has expanded to grip the walls of the chamber, the base is then driven back, and this stretches the case to produce the hazardous bright-line, indicating an imminent failure.

While this is certainly true, I suggest that it is not the only cause, but a second stage that comes into play after the sidewall-stretch effect described above. . .

I've seen this idea in a lot of places, including some widely published manuals. Unfortunately, it's not not an accurate appreciation of the sequence of events when a rifle cartridge is fired. If you think about it, you'll understand why no brass is actually moving forward during firing.

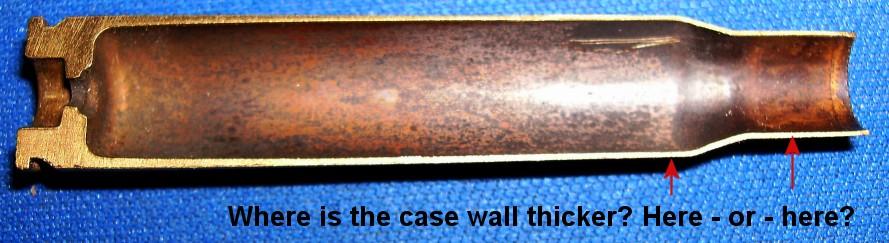

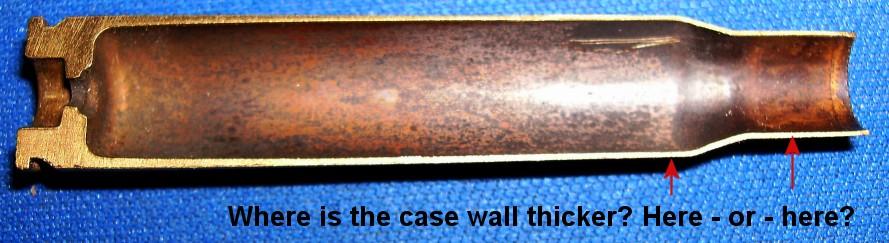

1. The very first part of the case to expand under firing pressure is, naturally enough, the thinnest, softest, weakest portion. In bottleneck cases, this thinnest portion is the area nearest the junction of body and shoulder. Thanks to the way cases are drawn, as cylinders with walls tapering toward the neck, the mouth is the thinnest portion only before the neck and shoulder are formed. When the new case is necked down from cylindrical to bottleneck form, the thickness of the neck increases, leaving it a bit thicker than the area immediately behind it. After the necking operation, the finished case is given a final neck and shoulder anneal, making the thinnest section also the softest.

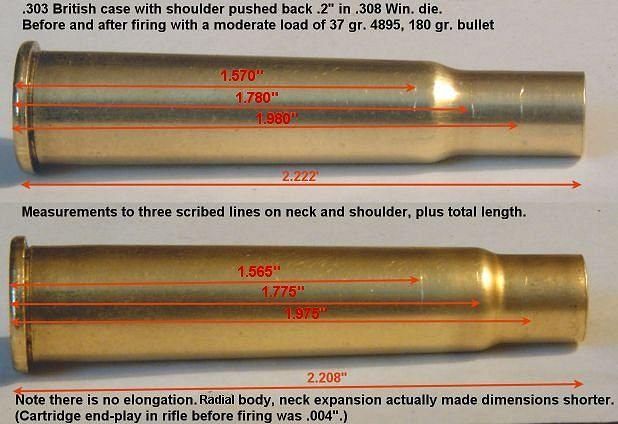

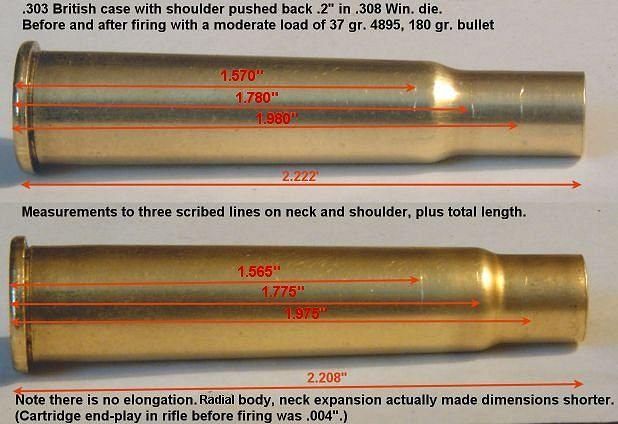

2. As pressure builds during powder combustion, this thinnest, weakest portion of the case expands outward to fill the chamber. Being a solid (at the highest temperature it normally reaches during firing), it cannot and does not "flow" forward. If you fire a cartridge with minimal end play ("head clearance"), or with effective lubrication between case and chamber, you will observe that its length actually diminishes as some material used to increase girth is "robbed" from length (the rest being robbed from thickness as the brass stretches radially).

(I suspect the oft-repeated assertion that brass "flows forward" during firing originated with handloaders who measured cases after firing and sizing but never bothered to measure fired cases before sizing. During full-length sizing, of course, the case is constrained at its base while the forward body and neck are reduced. With effective sizing lube present, the material displaced during this reduction escapes in the only direction open - forward into the neck. The result is a case with slightly thinner walls and measurably greater length than before it was fired.)

3. This initial expansion of the thiner sections occurs well before pressure rises high enough to stretch the heavy lower section (when end play is present or the bolt face is movable). If case and chamber are clean and dry, the expanded forward section now adheres firmly to the chamber, holding it in place against any further displacement of material. When pressure climbs enough to overcome the strength of the hard, heavy lower wall, it stretches somewhere between the unexpanded base and the expanded sidewall.

4. In rear-locking actions like the Lee, firing pressure also compresses the length of bolt between locking lugs and bolt face while simultaneously stretching that part of the receiver between lug recesses and breech face. This normal elastic response to the sharp thrust of the cartridge base on the bolt face adds to any case wall stretch due to cartridge end play. This is a significant reason we see diminished brass longevity with stiff handloads in the Lee-Enfield.

The same effect is observable when comparing Swiss 7.5 services rifles - the rear-locking 1911 vs. the front locking K31 - although this rimless cartridge suffers from none of the shoulder clearance issues ascribed to the Lee-Enfield.

7.5 services rifles - the rear-locking 1911 vs. the front locking K31 - although this rimless cartridge suffers from none of the shoulder clearance issues ascribed to the Lee-Enfield.

5. The supposed difference between shoulder positions of British service .303 cartridges and commercial production has been wildly exaggerated (perhaps based on some abnormal samples). In my experience, there is very little, if any, visible difference -

service .303 cartridges and commercial production has been wildly exaggerated (perhaps based on some abnormal samples). In my experience, there is very little, if any, visible difference -

6. One more point to consider: If brass stretching forward during firing were part of the problem, would initial firing with a spacer holding the case head back against the bolt face be effective for enhancing case longevity?

-

The Following 3 Members Say Thank You to Parashooter For This Useful Post:

PM

PM