-

Legacy Member

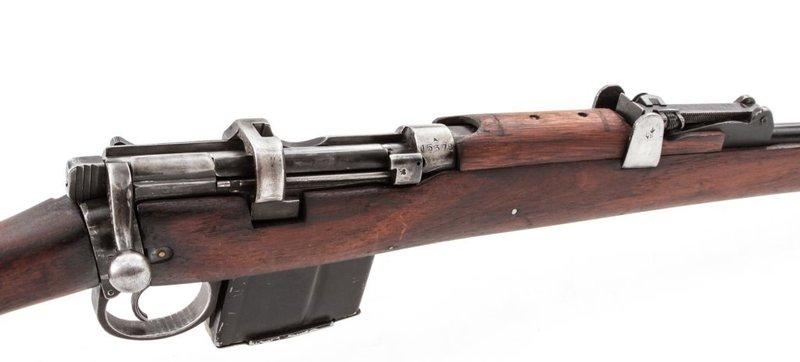

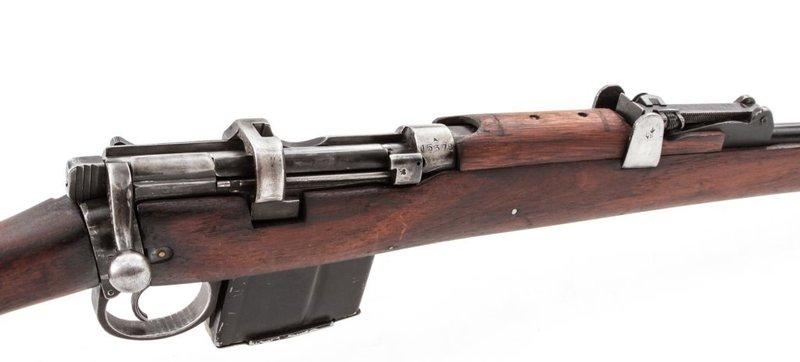

1st post! Ishapore 2a1 sporter restoration

Hello Milsurps!

This is my first thread here, and I hope I fit right in. If you catch me doing something I shouldn't, please slap me on the head with a strongly worded reply, but also let me know how to correct what I did wrong.

I recently acquired an Ishapore 2a1 sporter. Wanted an enfield in 7.62 and wanted a sporter to give some TLC to. The barrel, receiver, bolt body, rear sight leaf, and magazine all match.

Dumb things I did:

- Not firing the rifle before proceeding with teardown

- Not reading articles, books, and posts here before I started

My plan is to:

- Fit new fore stock

- fit nose cap

- fit forward handguard

- re-fix butt stock

- fit butt pad better

- refinish metal to protect it (probably parkerize)

- obviously get as many parts as needed to restore to military configuration

Here is the rifle I got:

************************************************** *************************

Work has begun:

Broke the rifle down to all the bits. Couldn't remove the rear sight base, but was able to remove the front sight base and key.

Removed the remaining paint patches (mixed paint by the way) and de-blued the parts:

While I was waiting on the fore stock and other parts, I decided to tackle the butt stock:

Will be using a piece of walnut from the shortened, crached, and poorly fitted fore stock:

New Fore stock arrived. I didn't notice a problem right away, and began fitting at the same time as trying to understand how to properly fit it.

after getting it on the receiver and then watching some videos I realized that I got lucky. The sides are apparently not required to hug the receiver, so my gaps are not all that horrible, but ugly.

And then I see this!!! The stock is warped!!!

Off to steaming the stock:

And reverse twisting using leather shims under the opposite edges of the stock.

Worked!!! But the nose cap machining was actually done on the twisted stock, so the holes are off axis.... This makes the nose cap sit nicely while not secured, but the moment you put the screws in, it cants by 20-25 degrees. Here it is loosely placed on the forestock.

Butt stock re-patched:

Butt plate fitted a little better:

As I learned, the wood was supposed to be removed from the back side of the fore stock, so I patched up the recesses inside that I prematurely cut (not knowing how to fit the fore stock correctly)

Getting pretty good contact on the back side now, and the fore stock now fits tightly onto the receiver.

Starting to shape:

Constantly checking barrel alignment and making sure (according to the now-seen videos) the barrels floats where it should and rests where it should.

Nose cap slips right on...

Alignment is not bad:

Got some of the gun oil and grease out of the stock using the calcium carbonate / acetone mix

I think I understand how the receiver should be bedded, so...

Shaping the fore stock to match the receiver and trigger guard (yes, after making sure the trigger guard is properly straightened and has good contact).

And now, I am bedding the nose cap... Since I had to change the direction of the screw holes, and force the nose cap to sit correctly... Will update when that is done.

So... Please let me know what I am doing wrong, etc. (I have another fore stock on hand).

Thank you in advance.

MV.

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

The Following 9 Members Say Thank You to MosinVirus For This Useful Post:

-

03-22-2016 07:15 PM

# ADS

Friends and Sponsors

-

FREE MEMBER

NO Posting or PM's Allowed

Welcome to Milsurps. Nice Job. Thanks for sharing. Not many are willing to put the time and effort into restoring a sporter.

(I'd guess Captain Laidler will suggest to you that the oak pegs be put into the repair on the butt adjoining the butt plate

will suggest to you that the oak pegs be put into the repair on the butt adjoining the butt plate )

)

Good luck with the next stages.

-

-

Legacy Member

Originally Posted by

Seaspriter

Welcome to Milsurps. Nice Job. Thanks for sharing. Not many are willing to put the time and effort into restoring a sporter.

(I'd guess Captain

Laidler

will suggest to you that the oak pegs be put into the repair on the butt adjoining the butt plate

)

Good luck with the next stages.

Thank you. I have some pegs on the inside of the repair, as in, I drilled both the patch and the stock, and when gluing together put the pegs into respective holes. Meanwhile I was thinking how if those pegs were "threaded" they would probably hold even better, but I roughed them up nicely so there should be plenty of Grab-n-hold.

-

Thank You to MosinVirus For This Useful Post:

-

Contributing Member

Great article and photos.

IMO very good wood work/craftsmanship.

Ed

-

-

Legacy Member

Originally Posted by

ed skeels

Great article and photos.

IMO very good wood work/craftsmanship.

Ed

Thank you. Still not sure if I will be using this forestock or going with the other one I have. Not happy with the nose cap.

Also, can someone please confirm whether the buttstock should have a slight gap between the receiver socket and the corresponding shoulder on the buttstock, or if I should get the buttstock "married" to the receiver better? I mean u could try and make sure that the head of the stock contacts the receiver at the same time as the "shoulder" contacts the socket wall edge.

-

-

There should be a gap between the butt and the butt socket when the stock bolt is done up what we call 'xxxxing tight'. We say about 1/16". This is because the butt is seated tight within the taper of the butt socket and not along that edge..

I know the more expert will disagree with me on this..... but......... There are two types of wood. Wood that HAS warped and wood that hasn't warped - YET! If your fore-end has warped then you can steam and oil and all these other things but it WILL revert back to how the natural tendency of the wood takes it. Fit a non warped one while it's apart! If you refit a warped/straightened fore-end you will never trust the rifles accuracy again. Just my opinion based on nothing more positive than experience

We peg our wood patches to illustrate that they have been done properly, by Armourers and that they'll last for 100 years

Brian at BDL in SC has superb UK

in SC has superb UK Military phosphating facilities. I bet he could set your bolt and CHS up while it's there

Military phosphating facilities. I bet he could set your bolt and CHS up while it's there

-

The Following 3 Members Say Thank You to Peter Laidler For This Useful Post:

-

FREE MEMBER

NO Posting or PM's Allowed

Brian at

BDL

in SC has superb

UK

Military phosphating facilities

Brian Dick phosphate two Lee Enfields for me, with superb results. Excellent quality -- first class.

phosphate two Lee Enfields for me, with superb results. Excellent quality -- first class.

-

Legacy Member

There should be a gap between the butt and the butt socket when the stock bolt is done up what we call 'xxxxing tight'. We say about 1/16". This is because the butt is seated tight within the taper of the butt socket and not along that edge..

I know the more expert will disagree with me on this..... but......... There are two types of wood. Wood that HAS warped and wood that hasn't warped - YET! If your fore-end has warped then you can steam and oil and all these other things but it WILL revert back to how the natural tendency of the wood takes it. Fit a non warped one while it's apart! If you refit a warped/straightened fore-end you will never trust the rifles accuracy again. Just my opinion based on nothing more positive than experience

We peg our wood patches to illustrate that they have been done properly, by Armourers and that they'll last for 100 years

Brian at

BDL

in SC has superb

UK

Military phosphating facilities. I bet he could set your bolt and CHS up while it's there

Thank you very much for the information. I am no expert in anything, so no arguments here.

I started fitting the new forestock last night. Got it fitting very tight, realized that its inletting will not let it sit high enough on the receiver. I haven't really checked where it makes contact yet, but by the feel of it I think it is at the barrel/receiver joint.

In any case, the new forestock is warped in the opposite direction to the first one , and also bent at the same spot.

So, I guess this one is also junk, based on what you just posted. Do you by chance have a source for better forestock for 7,62?

Thank you for confirming the buttstock fit. I will make sure to leave a gap.

Does CHS mean check head space?

Originally Posted by

Seaspriter

Brian Dick

phosphate two Lee Enfields for me, with superb results. Excellent quality -- first class.

Thank you. I will certainly contact him.

-

-

Legacy Member

-

Thank You to MosinVirus For This Useful Post:

-

Legacy Member

So, I just got a new butt stock today. And fitted it. Very tight, with a 1/16" gap between the socket and the shoulder of the stock. Tried to put the bolt in as far as it will go and it only gets to about half way into the socket. With the old stock it sat just under the wall that faces the forestock. I took the new stock off and just tried to see how far the bolt will go in the stock itself to exclude possible misalignment issues with the receiver...

It went as far as before. Or not far enough. The tip of the bolt gets to about 1/4" short of being even with the head of the buttstock.

Could this bolt have been shortened?

-

PM

PM

)

)