-

Legacy Member

For those not wanting too much of a hassle trying to find a good tool for removing the split-face nuts, I have found suitable replacement ones pretty easily in most good hardware stores. These are slotted tips for the common hex-bit handles; the special one shown is cataloged as a "spanner" tip. See picture. I use the 1/4" bit, #12 as shown.

You can deepen the slot to any length or width needed.

-TomH

-

The Following 2 Members Say Thank You to TactAdv For This Useful Post:

-

05-06-2017 08:33 PM

# ADS

Friends and Sponsors

-

Legacy Member

Thank you very much for your helps!

I have thought to build a tool similar to this one, but of smaller diameter.

This will ensure that the nut is held perpendicular to the shaft.

-

Thank You to Luis Bren For This Useful Post:

-

-

Legacy Member

If you strip ( cross thread ) the nut and the stem you can re-thread them with metric M5x.5 die and tap. This size is very close and will work . And the die and tap cost less than $15..00 with shipping.

-

The Following 3 Members Say Thank You to tr63 For This Useful Post:

-

Legacy Member

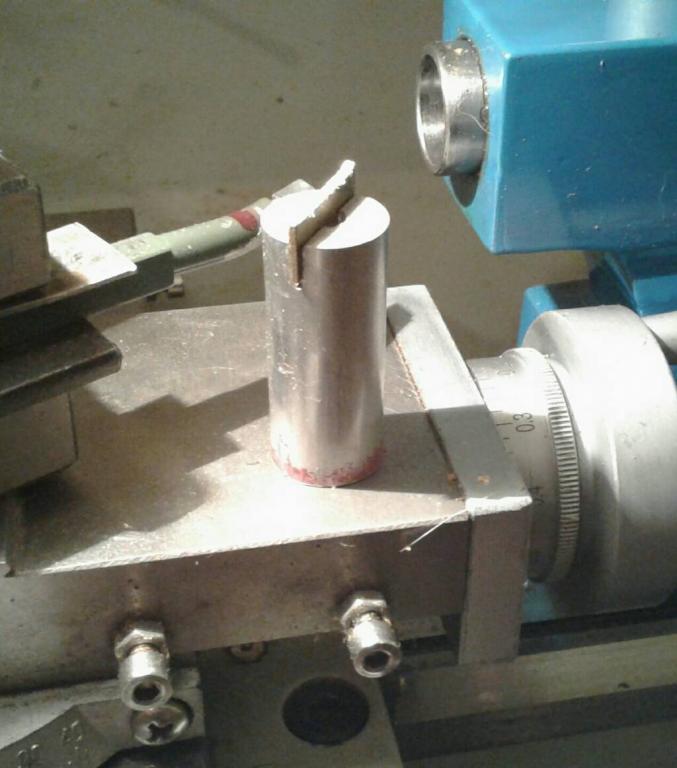

This is one I made quickly from scrap a few years ago after cross threading a nut. It works every time with out fail. I had it out doing some BSA handles so grabbed some photos.

Attachment 83714Attachment 83713

-

The Following 2 Members Say Thank You to Brit plumber For This Useful Post:

-

The one in thread 12 is identical to the ones we made during our apprenticeships. And I've still got it! 54 years and still going strong.

It ensures that a) it will only go into the hole in the grip square on and b) that the nut sits on the tool absolutely square and c) it will do both the outer and inner nut.

These old time Armourers have got to get up to date and get out a bit more haven't they........?

Last edited by Peter Laidler; 05-07-2017 at 06:17 AM.

-

The Following 2 Members Say Thank You to Peter Laidler For This Useful Post:

-

Legacy Member

-

Thank You to Luis Bren For This Useful Post:

-

Legacy Member

Now that I have been able to screw the nut easily with that piece of sheetmetal, I will try to make with the file and the lathe the tool that shows us britplumber!!

Last edited by Luis Bren; 05-08-2017 at 08:25 PM.

Luis

-

-

Legacy Member

-

-

That tool is all very well - providing that the nut doesn't need to screw down past the end of the carrying handle catch (shown in thread 12). If it does, it's useless because your tool will bottom out! You'll need to make it just like those old fashioned Armourers made them - Large diameter hole, as per thread 12. Then it will do BOTH jobs, properly.

Reminds me of my friends leaky MGB gearbox in a manner of speaking. I told him to take the inspection cover off and check that the filler plug wasn't leaking. He didn't...., but did look down from down and along the engine bay. A week later he told me that there was STILL oil leaking from about that point. So I asked whether he had done what I suggested. Well.....,, yes and no was the reply. He had looked DOWN at the filler plug area. 'But I suggested that you look AT the filler plug, side-on' I said. When the inspection hatch was removed and it was looked at PROPERLY, sure enough, oil was badly leaking from the bottom of said filler plug. I told him "..... it's no good looking from the TOP of the filler plug, just do it properly because the oil is leaking from the BOTTOM". Problem solved

Last edited by Peter Laidler; 05-15-2017 at 06:58 AM.

Reason: clarify a point

-

Thank You to Peter Laidler For This Useful Post:

-

Legacy Member

I made one like the one shown in post 12 however it didn't last long. The problem wasn't the tool but the lack of maintenance carried out on the Brens on the UK market and the seized nut ripped the prongs off.

market and the seized nut ripped the prongs off.

I only use my tool for putting the fiddly nut on now, the big nut I use the multi tool but I put the nut into the handle first and then insert the stem. Keeps it all square. As you will probably agree Peter, lots of these fiddly assemblies are an acquired technique.

-

The Following 2 Members Say Thank You to Brit plumber For This Useful Post:

PM

PM

i was able to screw again the nut!

i was able to screw again the nut!