-

Contributing Member

Originally Posted by

Sapper740

micmacman, yes it's difficult to build a completely accurate M16A1. I built mine a long time ago when NoDak Spud was the only game in town for retro lowers. Fortunately, I grabbed a couple of the short lived Sportsman's Guide's M16A1 parts kits while they were available and built myself a very good replica of the rifle, no fun button, of course. I take it out now and then to Carbine matches at my club which brings a laugh from everyone since I usually bring one of my custom built full-race AR's.

yup , i always meant to grab one of NoDaks top cocker uppers ,put it off for too long , when i went to go and grab it they were out ,and as you know they just stopped the retro line all together , are they even still in business?

---------- Post added at 07:50 AM ---------- Previous post was at 07:41 AM ----------

Too bad, I've had about three steel old style wrenches here that I've been using forever. They've never let me down...

i am seriously doubting Colt used any anti seize or nut butter , once i get the D ring cut off i will score the barrel nut on opposite sides and touch some heat , and the pipe wrench will do the rest , scoring the sides is a trick i figured out removing neutered Mak90 front sight bases ,it allows the metal to flex just enough that when you apply pressure it relieves its grip it has enough to allow it to free up

-

Thank You to micmacman For This Useful Post:

-

02-01-2024 08:50 AM

# ADS

Friends and Sponsors

-

Contributing Member

Originally Posted by

micmacman

i painted the receivers

I built an A2 clone (loosely defined) from an original colt upper I found. The upper had original dark grey, slightly green tinged, finish. I wasn't able to find a clean, non-billboard lower with actual words on the safety selector, so I went with a "Property Of" repop lower from palmetto state when they became available. The black anodizing, and not very good prep underneath (markings had a faded halo around them) bugged me to no end. After a lot of reading, I went with Norrel's molycoat and a cheap harbor freight airbrush kit. BANG. so easy. it adheres wonderful over the original anodizing (after degreasing). Went with the "Colt Gray". Ended up being a small touch lighter than the upper, but it passes the 20ft stare test. I then bought a bottle of his Socom black, and did a test piece of aluminum bar. I think If I blend the two 50/50 it will be the perfect match to the late 90's, early 2000's A2's.

I highly recommend Norrell's molycoat for these things. Stay away from the rattle can's.

-

The Following 3 Members Say Thank You to ssgross For This Useful Post:

-

-

Contributing Member

i will definetly give that Molycoat a go , once i button up al the pokers i have in the fire currently im doing a A2 dissipater , A2 upper , carbine length barrel with rifle gas , rifle length A2 HG's , A2 2 position stock

-

-

Contributing Member

Originally Posted by

micmacman

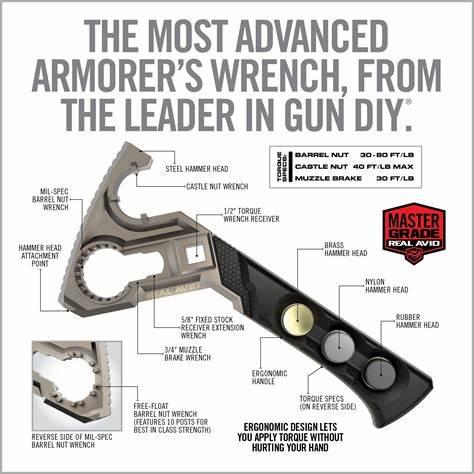

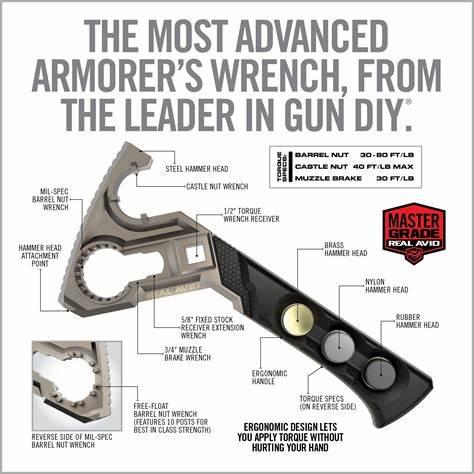

ran into a hiccup removing the barrel nut from the HBAR, it literally snapped 2 pins off my armorers wrench and when they let go it boogered up the nut , no big deal the FF tube has its own barrel nut , its a Rock River Arms NM A2 FF system, so I'm going to cut the D-ring off and touch a little heat to it and pipe wrench it off, don't ever buy a wheeler armorer wrench

Wheeler has a "Basic" with three pins, and a "Professional" with pins around the full half-circumference. Which was it? I use a 2-pin wrench for faster spinning the part on or off, but I use a full engagement of half-circumference wrench for full torque to install or remove.

-

-

Contributing Member

Originally Posted by

MAC702

Wheeler has a "Basic" with three pins, and a "Professional" with pins around the full half-circumference. Which was it? I use a 2-pin wrench for faster spinning the part on or off, but I use a full engagement of half-circumference wrench for full torque to install or remove.

the one i had it had the 3 pin on one side and the multiple on the other , which for what ever reason did not mesh upas well as the 3 pin so i was using the 3 pin , the Real Avid i have due tomorrow doesnt rely on pins

-

-

Advisory Panel

Very fancy... I use a strong arm on my little steel wrench and it didn't hurt me either. Just so they're aware.

-

-

Contributing Member

Originally Posted by

MAC702

Wheeler has a "Basic" with three pins, and a "Professional" with pins around the full half-circumference.

if I recall, the wheeler one you have to remove the front post to get at the nut. There is a very high quality and $cheap$ one I found on eBay that a guy makes himself which is a crescent, just wide enough to slip around heavy barrel. If you grind the ends a bit more open, it slips over a free float tube to get at its nut as well. Searched for it just now and don't think he's making them anymore. I think my wheeler wrench is kicked under a toolbox...somewhere.

-

-

Contributing Member

-

-

Contributing Member

Originally Posted by

Sapper740

they do , the wheeler was a $40 wrench the Real Avid is a $80 with not a single bad review , i iike the handle because your not grabbing sharp edges , is an actual edges not just the other end of a multi toll , i bought the wheeler because at the time i was outfitting with all the tools and served me well untill i put it on that bear of a barrel nut

-

Thank You to micmacman For This Useful Post:

-

Legacy Member

Nice work on the distressing of the finish. Looks "been there done that"

-

The Following 2 Members Say Thank You to HOOKED ON HISTORY For This Useful Post:

PM

PM