-

FREE MEMBER

NO Posting or PM's Allowed

-

02-02-2011 11:15 PM

# ADS

Friends and Sponsors

-

Advisory Panel

Interim comments - more to follow

Originally Posted by

killforfood

Surprisingly when I look down the barrel with my naked eye, it actually looks pretty good. Using +2.00 diopter reading glasses, it appears as a mild rough spot in otherwise smooth rifling. For now I’m not going to worry about it. I’ll concentrate on correcting the front sight, my own sight ....

100% agreement here. Correct the sight picture before doing anything else.

DId you take a close look at that foresight as I suggested. Spray it with the best penetrating oil you can find. Then a bit of tapping with the brass drift on the foresight blade, left-right AND fore-aft. Not heavy, but sharp taps. If there is a dovetail in either direction, then this micht just crack the bond enought that it shows up under a watchmaker's eyeglass. If you have not got one, such an eyeglass is a must. It is VITAL for the next problem...

Originally Posted by

killforfood

...and also do something about that horrendous trigger pull.

Joel, this is where it can get dangerous! I shall be posting a section on this problem.

Originally Posted by

killforfood

...If the accuracy is still unacceptable, then I’ll consider crowning or even back-boring (yuk!)but only if absolutely necessary.

That will also require its own section.

Patrick

-

-

-

Advisory Panel

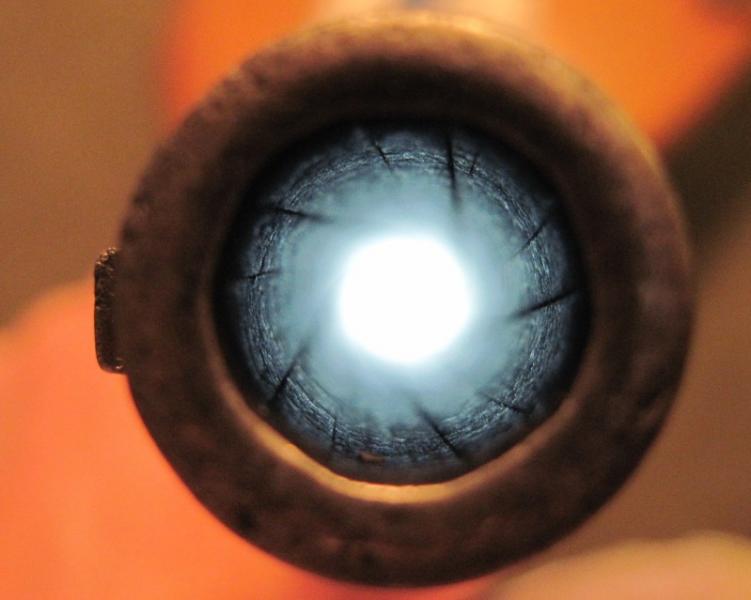

"Craters of the moon"

Good morning Joel, and thanks for the pictures of the muzzle.

The moon craters do, of course, look horrible, but as previously explained, after the fouling shot in a BPCR, the "crud-riding" effect means that they much less important than one might think, as long as they are small and average out as far as possible bullet deviation is concerned. The deeper scoring is much more significant. And most important is the muzzle itself. However, all is not lost. You have demonstrated that the rifle shoots without tumbling the bullets. The craters can be softened by polishing the bore with Neco lapping paste (look it up!). The muzzle will have to be the subject of a seperate section, and as I am presently composing some thoughts on the problem of the heavy trigger, the muzzle will have to wait for a couple of days.

Don't worry - we'll fix it!

Patrick

-

Thank You to Patrick Chadwick For This Useful Post:

-

FREE MEMBER

NO Posting or PM's Allowed

Patrick,

I’m fairly certain that the front sight does not have a dovetail but I’ll take a closer look with a jeweler’s loupe. I also at first thought I saw signs of a dovetail but I think its wishful thinking by both of us.

Rolling Block Parts offers a taller sight blade that would be correct for a #5 action.

I will need to measure my front sight base and see if it’s even large enough to allow a standard sized (whatever that is) dovetail cut. If I do cut a dovetail in the front sight, I will want to make sure that there is a good selection of blades that will fit. I hate one-off proprietary anything.

In the mean time I’ll probably hand file a brass blade and affix with JB Weld. At least this way I can experiment with blade heights and shapes without doing any permanent damage.

I’ve been giving trigger modifications some thought. On my modern firearms I’ve made extensive modifications to the triggers with no risk to collector value. I will need to be much more conservative with the rolling blocks case hardened surfaces. Rolling Block Parts offers a reduced pressure trigger return spring for $15 but I would rather bend my own. I keep a selection of music wire for just these occasions. I’ll take a close look at the engagement surfaces and see if they can be reduced or tolerate a slight angle change. This is where things can get controversial or downright unsafe. Years ago I had a so-called gunsmith reduce the trigger pull on an AR15. He messed up the timing so badly that I had to install a new trigger group. I’ve not allowed anyone, gunsmith or not, to touch my triggers since. I should’ve thanked him. His incompetence forced me to learn one of the most gratifying modifications that can be done to a good rifle. I will pit my 10/22 or AR15 triggers with modified stock parts up against any of those fancy shmancy $200 drop in contraptions. OK enough bragging. I’ll be extremely lucky to cut the rolling blocks trigger pull weight in half and even at that it will be twice what a good trigger should be.

Patrick, I look forward to your suggestions in this area.

Joel.

-

Advisory Panel

Refurbishing an Argentine RB - Part 17 - some thoughts on the trigger

Originally Posted by

killforfood

....and also do something about that horrendous trigger pull....

Joel, before you do anything with the trigger action, please read the following.

SAFETY WARNING

Trying to adjust the trigger pull is potentially very dangerous! This is one field where you must either go to a gunsmith who knows something about old rifles (they are not common) or LARs (Winchesters have a similar trigger mechanism, and often an enormously heavy trigger, maybe out of fear of "manufacturer's responsibility") or just leave it.

If you do anything yourself you are walking a high wire without a safety net. But it is no bad idea to have a better understanding of the way trigger components interact, so you can at least make a plausibility check on what the gunsmith says and does. And bearing in mind your previous bad experience, ask in detail what he intends to do before he does something irreversible.

Many old rifles have been ruined by incompetent work on the trigger setup. It is one of Bubba’s favorite fields of activity. He thinks “a quick touch with the file, and hey presto, I have a lighter trigger pull”.

NEVER touch any engagement surfaces! On rifles of this vintage they are case-hardened, and filing or grinding will rapidly cut through the case-hardening. The result is a trigger that may, initially, seem to be improved, but will rapidly wear to the point that it becomes dangerous.

There are 4 points to be studied. Get out the exploded drawing you posted at the beginning of this series:

1) The trigger spring. Item 27 in the drawing. This bears down on the back ledge of the trigger itself (Item 31. Its function is to lever up the trigger and push the sear (the engagement surface at the front of the trigger, which engages with the cocking notch) into the noch and hold it there. As the spring is a through-hardened item it can be lightened by very cautious grinding along its length, on the top surface, away from the engagement surface. But the lightening effect is minor, and it is dangerous if the spring is so weak that the rifle will not cock reliably.

2) The mainspring. Item 23. This can also be lightened. The downside is that it can easily be made so weak that the hammer will not ignite the primers. As the springs were originally made to some nowadays-unknown specification that must have produced an acceptable value with acceptable tolerances, and springs usually weaken with age, excessive spring stiffness is not usually the cause of trouble.

3) The sear. This is the engagement surface at the front of the trigger lever. Its engagement with the cocking notch on the hammer (Item 10) is the most critical part of trigger action, and the part most frequently ruined by Bubba. To inspect the sear and the cocking notch, you need that eyeglass I mentioned a couple of times! Ideally, under the eyeglass the sear should show a clean edge, slightly polished with use, not rounded more than a couple of thou, and without burrs or notches. Typically, a good sear is effectively glass hard on the surface, and severe wear is more likely to have occurred in the next component...

4) The cocking notch. Take a look at the hammer. Item 10.

There are actually 2 notches. The one at the front is deeper than the notch at the back. This is the half-cock notch. When you half-cock the RB, as I recommended for the cartridge length/head clearance measurements, the sear slips into this notch and holds the hammer out of contact with the firing pin. A relic of muzzle-loading days, this was intended to allow the shooter to carry the rifle loaded but not fully cocked. A useful function that combined readiness with a measure of safety before modern rifles were designed with full-cock safety catches. To ensure a function that is secure against extreme vibration or accidental contact with the trigger, the half-cock notch is cut very deep. You can see under the eyeglass that the half-cock notch AND THE SEAR have a negative rake angle, like a pawl in a ratchet, so that the pressure of the mainspring acts to tighten them together. The capital letters in the previous sentence are to draw your attention to the most frequent form of dangerous Bubbaring - filing or grinding of the sear.

The danger becomes apparent if you now study the cocking notch. Whereas the half-cock notch is usually so deep that it will hold the sear even if the sear surface is damaged or rounded off, the engagement of the sear and cocking notch is much more critical.

THIS INTERACTION IS THE MOST CRITICAL (AND POTENTIALLY DANGEROUS) PART OF THE MECHANISM.

You really must have an eyeglass to evaluate it. The cocking notch is much shallower than the half-cock notch. And the negative rake angle on the cocking notch is much finer. The larger the negative rake, the firmer the “hook” action of notch and sear, and the harder it is to press the trigger. Reduce the angle, and it becomes lighter. Make the angle positive, and the rifle cannot hold full-cock at all. As the angle approaches zero, it becomes progressively more dangerous, as the “hook” action becomes unreliable, until any vibration will suffice to trigger the rifle. And the angles on the two engaging components must match, otherwise there will be a contact along a line, rather than an area, and this too will lead to excessive wear.

Unfortunately, this is exactly where Bubba likes to play. Filing off the sear edge soon cuts through the case-hardening. The edge may seem sharp, but soon wears and becomes rounded, this means that the engagement with the cocking notch becomes dangerous, and another rifle is passed on to an unsuspecting buyer. Which is why the buyer must always be suspicious of any old rifle which seems to have a nice light trigger action!

As I mentioned before, a good sear is glass hard on the surface. Any wear or Bubbaring will usually result in a lighter not a heavier trigger pull. As springs do not normally become stiffer with age, rather the reverse, an unusually stiff trigger pull is therefore more likely to be the result of wear, burring or corrosion in the cocking notch. This can be corrected, but should be undertaken by a gunsmith.

The other factor not yet considered is the depth of engagement. You can see how not only the rake, but also the sheer depth of the half-cock notch makes it impossible to “fire” at half-cock with a normal human finger. Firing at full cock means applying enough force to pull the sear back out of the notch against 1) the trigger spring (fairly weak) and 2) the mainspring (very strong) over a sufficient distance that it slips out of engagement. So if the trigger is extraordinarily heavy, it may be that the notch is too deep, as a result of wear or corrosion. A VERY cautious reduction of the depth of the cocking notch can thus effectively reduce the trigger weight, without changing anything else.

Somewhere on the internet I once found a diagram of what needed to be done. It was nothing more complex than soldering a piece of brass or nickel-silver into the cocking notch, and then filing this down (very carefully, to avoid damaging the corner of the cocking ledge) to achieve a safe let-off. On double-set triggers, this effect is achieved by the little adjusting screw between the two triggers, and, like a double-set trigger, if you go a gnat's whisker too far you will have a trigger that is dangerously sensitive or does not hold at all.

I am sorry to hear that you had such a dismal experience with a gunsmith. The best answer would be if you could find one who is a real craftsman, and not a part-swapper. Like real mechanical clockmakers, they are getting rare. Mechanical craftsmanship takes time, time costs money, and too many customers just want a quick, cheap fix. The best way is probably by asking around to find one that others with similar problems can recommend from good experience.

I must repeat the warning: If you do this kind of work yourself, you are walking a high wire without a safety net.

Patrick

Last edited by Patrick Chadwick; 02-03-2011 at 01:39 PM.

-

-

FREE MEMBER

NO Posting or PM's Allowed

I just called Kenn Womack at Rolling Block Parts to order my cleaning rod. We talked about my sight problem and he mentioned that he used to own a rifle nearly identical to mine. It had a novel solution to correct the front sight height and allowed for correction of windage as well. The attachment fits over the original sight and is held in place with a set screw. It can be removed at any time with no damage to the original sight. He sold the rifle to a gentleman that actively shoots competition with it and that lives fairly close to me. Kenn was kind enough to give me the gentleman’s phone number. I’ll see if I can get pictures.

Patrick,

I will need some time to digest your latest post. I appreciate the obviously extensive effort that went into penning it.

Thanks, Joel.

Last edited by killforfood; 02-03-2011 at 02:19 PM.

-

Advisory Panel

Originally Posted by

killforfood

I just called Kenn Womack at Rolling Block Parts to order my cleaning rod. We talked about my sight problem and he mentioned that he used to own a rifle nearly identical to mine. It had a novel solution to correct the front sight height and allowed for correction of windage as well. The attachment fits over the original sight and is held in place with a set screw. It can be removed at any time with no damage to the original sight.

That sounds like a good idea. A very good idea indeed!

Patrick

-

-

Advisory Panel

Last edited by Patrick Chadwick; 12-29-2021 at 11:18 AM.

-

-

FREE MEMBER

NO Posting or PM's Allowed

Information

Hello

This information may be interesting to usted.En pages (181-211) marked inside the book (Note: the numbering does not correspond to the PDF-189-221), is a complete dissection of the rifle to Remington model 1870.Espero helps.

regards[

Download Armas-de-fuego.Barado-y-Genova-1881.pdf - BitShare.com - Free File Hosting and Cloud Storage

-

Legacy Member

a bit of patience will pay you a lot

As most of the other guys have said.

Take a good look at it and clean it, then assess the barrel and springs. your rifle looks all original and untouched, well worth saving.

I have several of these Argentinian RB's, they are 11.15x58 calibre, the EN on the barrel flat says it's an Army issue. Even what looks like a 'bad' bore will shoot well, cases can be easily made from the .348 Winchester ones, and if you do need action springs, send me a PM as I have a lot of parts, actions, trigger guards with springs and screws, I can set you up with what you need.

It's a good rifle to shoot, more powerful than your average BP RB, plus it has the later rotary extractor. As to your woodwork, try an Oxalic acid solution on the oil stained areas, this will bleach the muck out and a rub with linseed/turps (50/50) mix will restore the color.

Keep us up to date and good luck

Col

-

Register To Reply

Register To Reply