-

FREE MEMBER

NO Posting or PM's Allowed

Cracked necks in 6.5 x 55 brass.

-

04-17-2010 08:42 PM

# ADS

Friends and Sponsors

-

Advisory Panel

I have seen such cracking in only 2 situations:

1) Cases that had been resized over and over again.

2) Very ancient milsurp cases that had been rotted by the powder.

How old were the rounds that you fired? Were they, maybe, stored at above-average temperatures. That, at any time in the past, could have initiated chemical degeneration and internal corrosion of the brass.

Is your neck sizer really only sizing the neck? The neck should be lightly lubricated, and after sizing you should see a line just above the start of the neck where the lube has been pushed back. Swedish Mausers have chambers a touch longer than a SAAMI gauge would approve of, and are sometimes mistakenly thought to have excessive headspace when they are, in fact, in perfect shape.

Mausers have chambers a touch longer than a SAAMI gauge would approve of, and are sometimes mistakenly thought to have excessive headspace when they are, in fact, in perfect shape.

Do the "lubeline" check. You may need to back off the necksizing die about 1/64". But in spite of that, I think you have a dud lot of ammo.

Patrick

-

-

-

FREE MEMBER

NO Posting or PM's Allowed

Patrick...

I purchased the Winchester rounds new and save the brass several month ago. I'll have to double check the lube line test. All I can say for now is that the jacketed Match King bullets seat quite well. And I had only reloaded the brass twice.

Thanks for your thoughts.

-

FREE MEMBER

NO Posting or PM's Allowed

I´ve never had this in my Swede. I agree with Patrick and think you had some bad cases in your Lot. Ahh wait, i´ve seen this one time by at my .303 by using cases from Federal ammo. I made a test that worked to 80%. After the necksizing i rubbed graphit dust ( from an pencil mine ) around the neck and polished it with an cloth away. The graphite stayed at some places and after firing this rounds there were cracks in the so marked cases. After this i bought new cases from PRVI and had no problem anymore.

Regards

Gunner

-

FREE MEMBER

NO Posting or PM's Allowed

If you have a bunch of these Winchester cases, I'd neck anneal them and see if you have better luck. I used to see this occasionally in some Herter 8X57 cases that were necked down for use in my 7X57 rifles. I'd also agree with just buying new Prvi Partizn brass.

-

FREE MEMBER

NO Posting or PM's Allowed

I would agree that annealing is a great thing to do, to the used cases before you resize them. I think you are crunching the neck/shoulder area with too much lube on the cases. And, have you taken apart the sizer die, and cleaned it out and swasbbed it? Also, I see little benefit in just neck sizing a military gun which is made loose anyway. Try all of the above, but get a sizing lube like the spray lube that puts very little lube on the case and spread it around on the case with your fingers to smooth it out and lessen the thickness.

-

FREE MEMBER

NO Posting or PM's Allowed

Common problem of this class of cases. Just like 5.56 cases and that family even when neck sizing only. Figure out at what firing most of the necks fail. Then back up two reloadings and anneal the necks with a neck annealing ring. You can purchase a commercial unit or make your own from copper tubing. I made mine many, many years ago. Check the internet for instructions.

The cause is from the convergence of gas flow in the sharp neck and the intensity in relation to the bore and the powder types (high energy = temp ) used to achieve the required velocity. It tempers this area badly in a couple firings. It’s the cutting torch effect.

Last edited by JBS; 04-19-2010 at 12:21 PM.

-

FREE MEMBER

NO Posting or PM's Allowed

Headspace?

One more thought,

I showed the brass to the guy at a local gunshop and he instantly suggested that the headspace might be too large and said it probably wasn't safe to fire the gun until a gunsmith checks it out. Does that make sense?

-

FREE MEMBER

NO Posting or PM's Allowed

Originally Posted by

Patrick Chadwick

I have seen such cracking in only 2 situations:

1) Cases that had been resized over and over again.

2) Very ancient milsurp cases that had been rotted by the powder.

How old were the rounds that you fired? Were they, maybe, stored at above-average temperatures. That, at any time in the past, could have initiated chemical degeneration and internal corrosion of the brass.

Is your neck sizer really only sizing the neck? The neck should be lightly lubricated, and after sizing you should see a line just above the start of the neck where the lube has been pushed back.

Swedish

Mausers have chambers a touch longer than a SAAMI gauge would approve of, and are sometimes mistakenly thought to have excessive headspace when they are, in fact, in perfect shape.

Do the "lubeline" check. You may need to back off the necksizing die about 1/64". But in spite of that, I think you have a dud lot of ammo.

Patrick

Not really, didnt seen this at an Swede anytime, and we have an lot of them at our Gun Club. Read again Patricks post.

Regards

Gunner

-

Advisory Panel

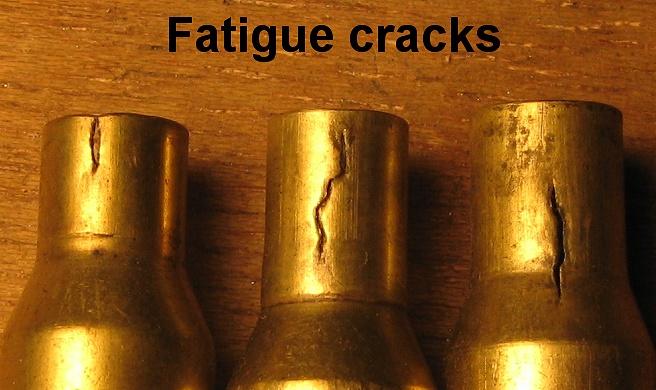

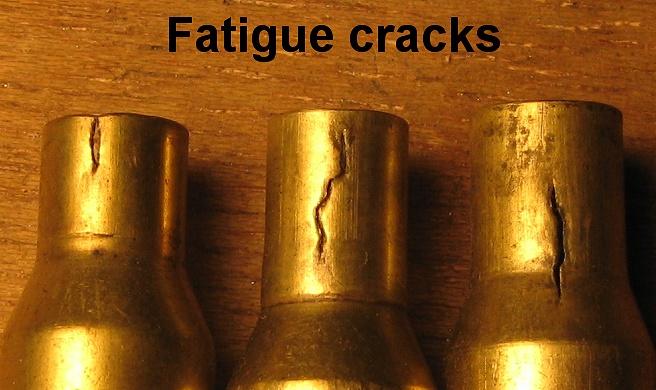

The case in bear's picture doesn't seem to show a typical fatigue crack. Look closely and you may see it was deeply scored, even displacing a bit of brass past the shoulder. This may have occurred during manufacture, sizing, bullet-seating, or feeding. Examine your sized cases for scratches from the sizer collet, completed cases for scratches during seating, and if none are found, remove the striker assembly and feed rounds into the chamber (from the magazine if that's how you are normally operating). Once you find the source of the scratches, a defect inside a die or something along the path the cartridge takes during feeding, correct it with appropriate tools.

-

6.5 x 55 model 96. She seems to shoot well with my reloads and I'm getting pretty good groups (a few 5 shot groups under 1" from 60 yards with open sights and my aging eyes.)

please.... all thoughts welcome!

Information

Register To Reply

Register To Reply