-

FREE MEMBER

NO Posting or PM's Allowed

Fire lapping a 303?

I'm reading an awesome book called the 1995 Precision Shooting Annual and there's a really interesting subject called fire lapping. I wondrin if we have any experience here with doing this to a 303 barrel or an H barrel? That leads to the question of, just what is the general state of the internal surface of a 303 barrel like when comparing machining or chattering marks? Are they good, bad, average? Are H barrels a paragon of top machining, or ...?

Would I be better off believing in the force before pulling the trigger?

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

10-12-2010 05:50 AM

# ADS

Friends and Sponsors

-

Advisory Panel

I don't think .303 barrels were any better or worse than others produced by similar methods. There was a period when a sample of No5 rifles were draw lapped at the factory, but IIRC there was no noticeable improvement in accuracy.

Do you have a new barrel? Unless it's had less than 200 rounds through it, the job is probably already done.

There has been a lot of discussion about artificially "running in" barrels. (benchies and varminters) Most seem to come to the decision that all you are doing is prematurely wearing the bore.

Follow a run in procedure like fire one round and clean- repeat for several rounds. Then fire five rounds and clean- repeat a few times. The idea is to wear off/smooth the high points without clogging the low points with copper.

-

The Following 3 Members Say Thank You to Son For This Useful Post:

-

-

Legacy Member

Having measured several MINT "H" barrels, ( the owners had to crack the seal on the factory bags to get the measurements); I have a few observations:

The bores of these barrels appear to have been lapped by hand to a very fine finish. In several samples, there is small, but measurable "belling" at the muzzle end.

The grooves, however, appear to be as they were left by the last pass of the rifling tool. Some are better than others.

I have not slugged any barrels to establish groove diameter variations. It gets tricky when trying to measure 5-groove jobs as well.

The problem with lapping of any rifled barrel is that the effect on the lands is greater than on the grooves. Original barrels were specified at .303" "accept" diameter of bore and with a reject diameter of .305". They were lapped BEFORE being rifled. If your grooves are looking a little "agricultural", there is not much you can do. Elbow grease and a stiff stainless steel brush may help, but probably not much. This is exacerbated by the fact that .303 military barrels can run out to .320" diameter, as per the various original factory drawings. A nominally .312" slug is not going to help much, no matter how much grinding paste you apply. You could try hammering a cast .323" (8mm) bullet through and going from there. Alternately, there is the technique of casting a slug onto the end of a rod that is centred in the barrel. Lotsa Fun!! Really early SMLE barrels that were factory lapped to a TAPER are a thing all on their own. Gauging them must have been a hoot!

The biggest problem with lapping, whether on a new or "pre-loved" barrel, is the risk of "belling", especially at the muzzle. For this reason, good barrel makers who pre-lap their barrels generally do several things to avoid annoying their customers.

1. Make the blank several inches longer than the nominal catalogue length.

2. Lap very carefully by hand, using guides to maintain co-axial travel of the lap.

3. CLEARLY indicate the breech and muzzle ends of the blank. Some makers put a saw-cut an inch or so back from the muzzle, just so you definitely get the hint. "Direction" of the rifling is especially important with buttoned barrels; marginally less so for cut-rifled types. Given that the breech-end is going to be opened out for the chamber, there is no real problem with a tiny amount of "belling" there.

Fire-Lapping works best on barrels that almost don't need it!

Unless you also have a nice stash of Mk7 projectiles or a pallet of Mk7 Z ammo, invoking "The Force" may be a good thing.

-

The Following 4 Members Say Thank You to Bruce_in_Oz For This Useful Post:

-

Advisory Panel

I have one of those taper-bored barrels on a rifle here. I think they bored and reamed first, then reamed the taper, then rifled to a constant diameter. When it has just been cleaned, it appears as if the first 6 inches of rifling are terribly worn, almost completely shot-out at the leade but improving markedly and regularly for exactly 8 inches from the bolt-face, but when you dry it out and look again, you can see that the rifling is sharp for the full length, lands are nice and sharp.

As you said, I have NO idea how they gauged them; only thing I can think of is that they were gauged before they were rifled. But then, that WAS over 100 years ago; skilled labour was cheap.

I have often wondered how a brand-new one would shoot, made with button rifling on modern equipment.

.

Last edited by smellie; 10-12-2010 at 03:56 PM.

Reason: clarify.... wrong word

-

Thank You to smellie For This Useful Post:

-

Banned

-

Banned

Originally Posted by

smellie

I have often wondered how a brand-new one would shoot, made with button rifling on modern equipment.

.

Smellie

I'm always amazed at how well an "old" Enfield shoots compared to the average new rifle, I broke my .243 in cleaning as recommended after each shot for 5 rounds and then every 5 rounds for 50 rounds. When I got home I let foam bore cleaner soak overnight and was amazed how much copper was still in the bore. Breaking in the new average button rifled bore with the cleaning regiment above is a waste of time. Shooting a new rifle and then using a bore brush and copper solvent will not take the rough high spots out of your bore, that only comes from shooting, age, or fire lapping.

The cleaning regiment does nothing for group size which were better the next trip to the range from a dry fouled bore.............only time will tell. (and a lot more shooting and reloading)

-

Legacy Member

A side note on tapered bores:

The barrels for the GE M134 "Minigun" are tapered internally. The spec. calls for the BORE to be tapered towards the muzzle. Groove diameter is more or less constant.

There were obviously gauges used by Ordnance inspectors. No doubt these gauges were to measure bore diameter at specified points from the breech end.

Apparently, Harrington and Richardson, who made a large quantity of these barrels, worked out a neat solution: a STEPPED bore. Instead of making an incredibly expensive, full-length reamer or having a herd of elves lapping them out by hand, they appear to have made a barrel with the minimum diameter rifling all the way and then run in (probably helical) reamers to achieve a "virtual" taper consisting of several stepped diameters. If they "gauged" OK and functioned to spec, what was the problem?

The finished barrels were full-length hard-chromed internally.

In a wonderfully strange historical convergence, some of these barrels found their way onto the small run of AIA "B3" rifles.

-

Thank You to Bruce_in_Oz For This Useful Post:

-

Legacy Member

Remember, "Broken in" is the beginning of "Worn out"!

Fire lapping or pressure lapping is not new and not a good idea, pressing lapping compound into your bore at 50,000 + PSI is not a good idea,

if you want to smooth or break in your bore the 2 correct methods are hand lapping (easy to do but also easy to screw up) or shooting, shoot, clean, look, shoot again repeat.

-

-

FREE MEMBER

NO Posting or PM's Allowed

The funniest story in the book is a police dept who bought a series of pre embedded loaded cartridges for a Galil; All four grits, 10 shots each, and 20 shots of 1200 grit', and as quick as you could cycle the gun and change 5 mags the job was done!

After a few warnings about that and the value of taking more time the comments are about a .308 that opened up from .3075 to .3095 (20 thou!) and get this, the groups went from 3 inches to 3/4".

There's other stories about rolling bullets in valve grinding paste to do the job, ... easiest way to end up with a shotgun I'd think.

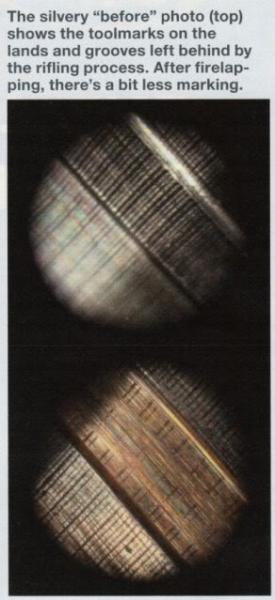

Those pics of Eds with the chattering marks are basically shocking, no wonder the copper hooks into the barrel.

Are there custom barrel makers who set out to make barrels that don't have chattering marks, seems there'd be quite a market, or do we have technology limitations?

Last edited by RJW NZ; 10-13-2010 at 12:04 AM.

-

Advisory Panel

Seeing those photos certainly makes one understand the benefits of "ball burnishing".

“There are invisible rulers who control the destinies of millions. It is not generally realized to what extent the words and actions of our most influential public men are dictated by shrewd persons operating behind the scenes.”

Edward Bernays, 1928

Much changes, much remains the same.

-

Information

Information

Register To Reply

Register To Reply