-

Legacy Member

Thank you Mr. Horton. Some more questions.

I don't know how I missed the .303 case gauge on the Wilson website.

I looked at the RCBS website, and saw their cartridge gauge, but saw they did not offer it in .303. I believe what you are telling me is that I can get .303 shoulder movement information from using the .308 RCBS Cartridge gauge. Is this true?

I am familiar with the differences in backthrust based on chamber conditions. I recently saw a series of pictures of .30-30 cartridge case heads with pressure indicating film on them: oiled cartridges showed the most pressure, followed by cartridges with the precise headspace of the chamber, the least pressure shown by chambers .010" over cartridge headspace. When studying action springyness, I'm going to have to pay particular attention to maintaining several standard chamber conditions: not just oil, but the same headspace.

-

-

04-06-2009 06:25 PM

# ADS

Friends and Sponsors

-

Banned

-

-

Legacy Member

EH posted

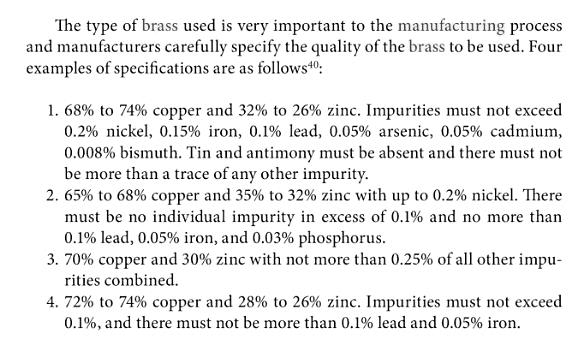

>>>If I remember correctly cartridge cases are made from five different grades or specifications of brass and American .303 cases are one or two grades below what would be used in the upper pressure category as in the .308 Winchester and above.<<<<

Do you have any citations to back this up?

-

-

Banned

-

Legacy Member

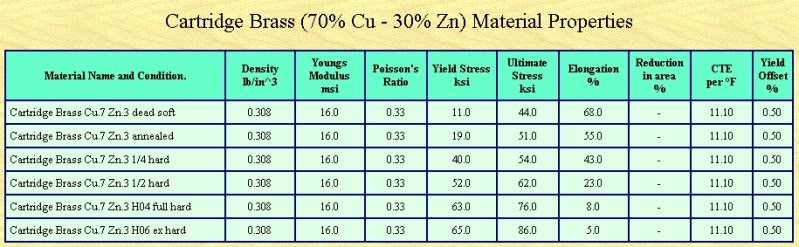

Your listing is of the different material conditions for 70/30cartridge brass.

Depending on how the cartridge is manufactured including annealing all the material conditions from full hard to annealed may be found in the same case. Some cases may even include the extra hard and dead soft condition.

If you would like to see the military specifications they can be found at the US government "Assist" web site. Pick the quick search option and enter key word for a title such as "cartridge"

As you learn to use the site you will figure out how to get to cartridge and then within that document you will find a specification for "brass, cartridge"

Last edited by ireload2; 06-04-2009 at 01:56 PM.

-

-

Banned

-

Legacy Member

-

Thank You to ireload2 For This Useful Post:

-

Banned

Ireload

You are not telling me anything I do not already know because I have been reloading for over 40 years and we have gone over all this before. The best method I have found for fire forming .303 cases is using the rubber o-ring method and you will have zero case stretching because you have zero head gap clearance.

In the posting at Gunboards that was deleted I went into detail on this method, in Parashooters Headspace 101 he used nylon monofilament instead of the rubber o-ring to hold the case against the bolt face and reloaded the cases 19 times without any case stretching.

The secret is in the fire forming and not letting the case stretching in the web area get started in the first place.

I also said before the American manufactures are loading factory ammunition to below 43,000 CUP and are using a lower pressure rated cartridge brass which makes them fall apart above that pressure.

-

Legacy Member

You may have a lot of reloading experience but so do I. Plus my entire working career had been involved in machining, metal working and engineering.

You assert good things about your method but have you actually shot any brass to destruction?

What size O ring are you using so I can duplicate your tests?

I would like to try the O rings with .444 brass and .405 brass.

One of the reasons that you may have found no thinning in the HXP brass you have I believe you said it had been fired in a machine gun. That might make a big difference if the machine guns is much heavier and stronger than a Lee-Enfield action.

Is the machine gun fired HXP still available anywhere.

Have you checked your fired brass in the Wilson gauge?

It seems you conveniently ignore my questions.

-

-

Banned

You are forgetting something very important here, I did not ask you for any advice nor do I want any of your advice, the main reason you came here is to extend the argument, fight, disagreement we had at Gunboards to this forum.

This thread last saw activity before you asked your question on April 6, 2009 and that was over a month ago, the only reason you are here is to stir up more trouble like you did at Gunboards. Take your grudge, ego and B.S. and go someplace else.

Have a nice day

PM

PM