-

regarding No 4 and No 5 rifle bedding

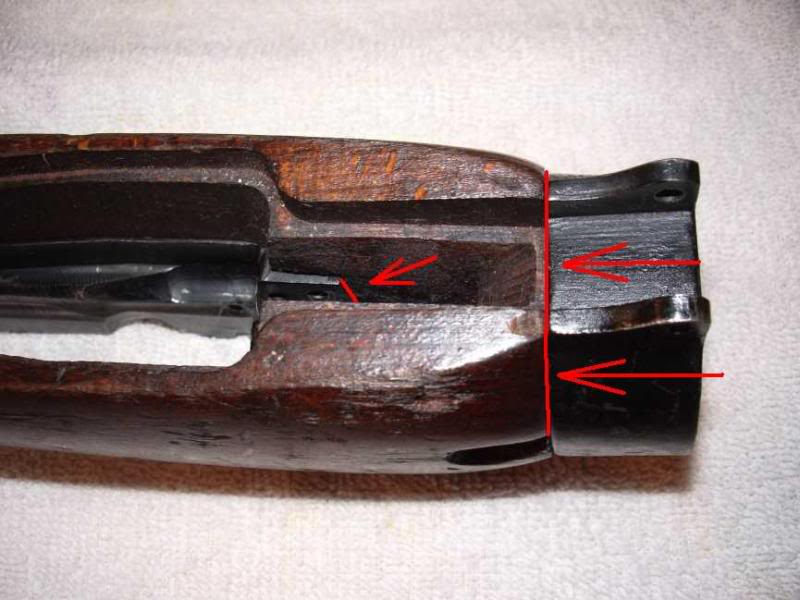

Hi, I've just bought a nice no5, and did a couple of small repairs to the woodwork(the forend). The barrel was sitting to the left hand side of the barrel channel, so i relieved the wood of the forend at the right hand side where it contacts the butt socket/collar. I appear to still have good contact on the wooden recoil shoiulders(I forget what they're called), but I've got a small gap between the collar and the forend. I could take it up with epoxy filler, but I want to keep this one original. Anyone know if this gap will adversely effect its performance, and if so the correct way to rectify it? NB. The gap is only a fraction of a millimeter, 1/4 or so.

Thanks

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

-

10-22-2009 02:55 AM

# ADS

Friends and Sponsors

-

Advisory Panel

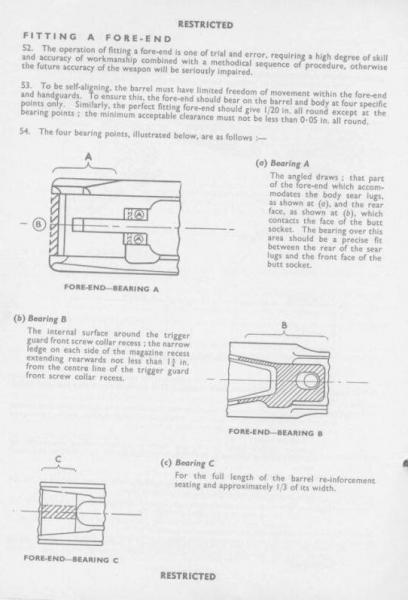

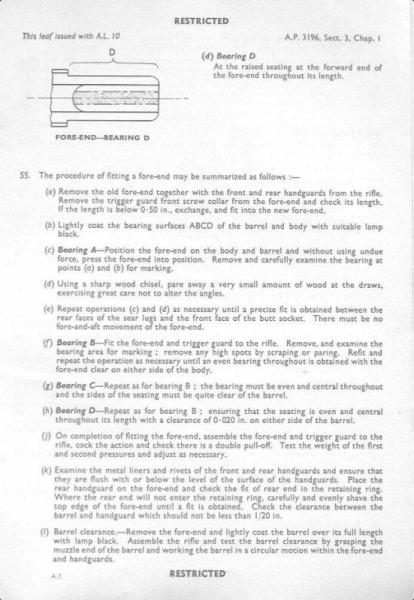

The gap between the recoil lugs and the butt socket should be completely filled by the wood of the draws. A gap may lead to movement of the forend during recoil, and subsequent accelerated wear of other bedding points - particularly the wood under the recoil lugs.

Filling the gap with adhesive tape or resin should give a firm forend fitment, and won't unduly alter the rifle. In service, a new forend would have been fitted anyway.

-

Thank You to Thunderbox For This Useful Post:

-

-

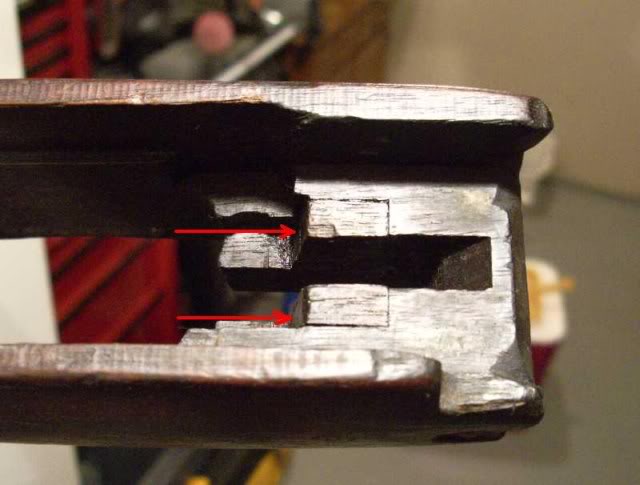

Adhesive tape or resin.....................!!!!! Shame on you Thunderbox! Armourers would chisel the old wood out, make good, then insert a patch of hardwood. Recut the draws and refit the fore-end. Young Armourers weren't allowed to fit new part unless one of the older Armourers (or the in-inspector) sanctioned it. And unless fore-ends were literally oil soaked or badly damaged as to be beyond patching, they were patched.

We called it pride in the job...........

I think that an article about patching the 'draws' has been published already T-bone. If not, just say so and I'll go through it for all to see

-

Thank You to Peter Laidler For This Useful Post:

-

i've searched for patching drawers and got no results, if you could run through the process I'd appreciate it.

-

-

Leave it with me and I'll find an old No5 fore-end to work on next week.

-

-

Banned

-

Legacy Member

Another photo of a arsenal repaired fore stock.

-

The Following 2 Members Say Thank You to SpikeDD For This Useful Post:

-

Banned

Hi, I've just bought a nice no5, and did a couple of small repairs to the woodwork(the forend). The barrel was sitting to the left hand side of the barrel channel, so i relieved the wood of the forend at the right hand side where it contacts the butt socket/collar. I appear to still have good contact on the wooden recoil shoiulders(I forget what they're called), but I've got a small gap between the collar and the forend. I could take it up with epoxy filler, but I want to keep this one original. Anyone know if this gap will adversely effect its performance, and if so the correct way to rectify it? NB. The gap is only a fraction of a millimeter, 1/4 or so.

Thanks

A gap that tiny would be best served by using accraglass bedding, if the wood is not oil soaked so badly as to require such radical measures as cutting away chunks and fitting pieces to replace the damaged wood.

A thin coat of accraglass would be much less noticable than attempting to duplicate the armorers repairs outlined, and probably more successful.

Afterall this sort of inletting work was not taken lightly.

A much worse case would be better served by the inletting of blocks suggested.

Also have you checked the trigger guard for signs of twisting or bending?

One No.1 fore end I fitted would look fine till the guard screws were tightened then it would shift to one side. I finally took a good look at the rails of the trigger guard and saw they were twisted. When tightened the twist put the whole thing out of whack. Once straightened everthing lined up perfectly.

Excessive oil in wood can be leeched away by heating the wood, and by soaking in a trisodium phosphate sollution then drying and repeating. When the solution dries it crystalizes and the crystals draw fat and oil into themselves and push to the surface.

I let dry till the crystals are visible then rinse with hydrogen peroxide solution.

Opening the pores and end grain with thinners, strippers, or acetone helps.

PS

For larger gaps I've used shims of wood veneer stripped from the backing of scrap paneling.

PPS

It just occurred to me that years ago I ran across the rules of a milsurp rifle competition and one thing they did not allow was glass bedding, the rifles had to be bedded just as they would have been in service.

That would probably apply to the target rifle bedding techniques as well. So if you intend to shoot in competition best check the rules for whatever gun club or organization is in control of the particular competition.

Last edited by Alfred; 10-22-2009 at 01:29 PM.

-

FREE MEMBER

NO Posting or PM's Allowed

Think you might be better off with a new fore-end. Making one from a cut down No. 4 Mk 1 fore-end is NOT difficult (and Peter says it was very often done by armourers too). And then bedding the action in with Acraglass and keeping the barrel free floating. When bedding, make sure that it goes in between where your gap is too. Don´t think clubs worry too much about bedding nowadays.

-

Banned

i've searched for patching drawers and got no results, if you could run through the process I'd appreciate it.

Its good to see you are practicing economizing in these grim times, but you might as well get yourself some new underwear. By the time they need patching the elastic is usually worn out anyway.

villiers Think you might be better off with a new fore-end. Making one from a cut down No. 4 Mk 1 fore-end is NOT difficult (and Peter says it was very often done by armourers too).

Unless the fore end is a wreck I think I'd rather repair a correct No.5 fore end than use a repro.

If I'm reading it right theres only 1/4 of a MM of daylight showing, hardly enough to call for anything radical.

Some fore ends could benefit from being relieved a bit at the front of the inletting and then the action being settled a bit further down into the wood.

Then any slack would be taken up by a thin shim on either side of the trigger guard.

Depends on how the action looks in the stock as is. Its pretty common to find enfields that sit a triffle high in the wood and with plenty of spare wood underneath.

PM

PM