-

Rivet Tail Variations on No4 Front Handguard Nosecaps

Rivet Tail Variations on No4 Front Handguard Nosecaps

Warning: Extreme Weapons Nerd (Anorakish) Alert!!!

Been studying the exposed rivet tails that retain the handguard nosecap metal a bit (!), lately and just found one lone NON Enfield manufactured assembly that has solid round exposed tails as opposed to the usual Tubular (countersunk looking tail) rivets. Just how common are these?

ID marks on this assembly include a small rounded (normal) "S" on the metal just behind the cutout, and a largish "(EG)" that has lines connecting the ends of the "(__)" top and bottom that is located in the center of the underside of the handguard. Unlike the Enfield "Trials Rifles" these rivet tails are uniformly rounded. Oddly enough, the rear metal clip IS retained by tubular rivets.

Have I missed the boat here, or are these solid rivets a bit unusual on a production No4?

BTW If you've made it this far, but don't know just what a "Tubular Rivet" is, well, in its "undriven" state it looks like a regular solid shanked rivet, but with a hole drilled into the end to a controlled depth. When used with special forming tools, they allow the fabricator to more easily assemble relatively fragile parts (such as thin wood sections) to other parts without damage. The forming tool will flare the hollow end a fixed amount so that it rolls over uniformly, securing the pieces with much less effort than cold forming a solid tailed rivet.

Sometimes I think its time to call the men in the white coats!

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

-

01-08-2010 08:09 PM

# ADS

Friends and Sponsors

-

Legacy Member

Come on now!!! Yellow Flag!!!

All this and NO PICTURES? What's the deal with this JM? Are you going to make me get out my shoe box of top wood and take pictures? By golly, I just might....

Originally Posted by

jmoore

Warning: Extreme Weapons Nerd (Anorakish) Alert!!!

Been studying the exposed rivet tails that retain the handguard nosecap metal a bit (!), lately and just found one lone NON Enfield manufactured assembly that has solid round exposed tails as opposed to the usual Tubular (countersunk looking tail) rivets. Just how common are these?

ID marks on this assembly include a small rounded (normal) "S" on the metal just behind the cutout, and a largish "(EG)" that has lines connecting the ends of the "(__)" top and bottom that is located in the center of the underside of the handguard. Unlike the Enfield "Trials Rifles" these rivet tails are uniformly rounded. Oddly enough, the rear metal clip IS retained by tubular rivets.

Have I missed the boat here, or are these solid rivets a bit unusual on a production No4?

BTW If you've made it this far, but don't know just what a "Tubular Rivet" is, well, in its "undriven" state it looks like a regular solid shanked rivet, but with a hole drilled into the end to a controlled depth. When used with special forming tools, they allow the fabricator to more easily assemble relatively fragile parts (such as thin wood sections) to other parts without damage. The forming tool will flare the hollow end a fixed amount so that it rolls over uniformly, securing the pieces with much less effort than cold forming a solid tailed rivet.

Sometimes I think its time to call the men in the white coats!

-

-

-

Originally Posted by

limpetmine

All this and NO PICTURES? What's the deal with this JM? Are you going to make me get out my shoe box of top wood and take pictures? By golly, I just might....

Regards,

Badger

-

-

Legacy Member

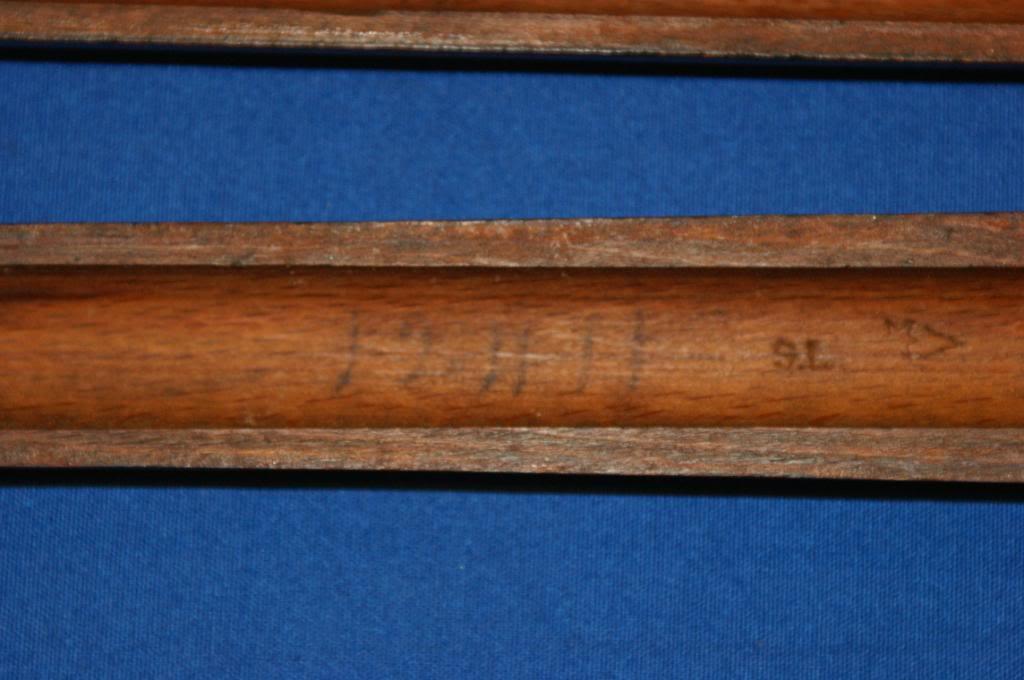

Various top wood rivets

Interesting subject-one that I've not thought about before. Note that the Savage rivets are not hollow as the British ones are. I must look at my LB's.

ones are. I must look at my LB's.

Last edited by limpetmine; 02-26-2010 at 10:47 AM.

-

The Following 3 Members Say Thank You to limpetmine For This Useful Post:

-

Legacy Member

Hollow rivets on my Savage 93C (bottom rivets are 'solid')

Fazakerly FTR in 1952 making it a No4 Mk1/3

Last edited by Alan de Enfield; 01-09-2010 at 05:33 AM.

Reason: bottom rivets

-

Thank You to Alan de Enfield For This Useful Post:

-

See what staying up 23hrs straight does to one's mind? I couldn't manage to loiter about any longer to take pics as its a 30min drive to the house, and I don't drive well while sleeping, unless they're REALLY short naps.

My 9C Savage has solid rivets, also. Oddly enough, due to the US Property marks, Savages are Bubba's favorite rifle around here, so that's my only good one.

Having bucked and squeezed a few rivets, I tend to pay more attention to them than most folk- that's my excuse anyways.

So Enfields, at least some Savages, and my mystery handguard have solids.

If you find some solids on yours -or tubular rivets on a Savage- please note the ID marks on the metal cap and on the wood (probably hidden underneath) and throw the info on here. Also, please note whether the wood in the cutout area was relieved for thr hinged forward band.

If you find some solids on yours -or tubular rivets on a Savage- please note the ID marks on the metal cap and on the wood (probably hidden underneath) and throw the info on here. Also, please note whether the wood in the cutout area was relieved for thr hinged forward band.

Cheap and quick "fun".

Pictures? You want steenkin' peectures? Well, OK, then:

Note the cutout in the wood.

Note- no cutout!

Remember Vultee, anyone?

The handguard riveting was MOST likely done in fixed tooling. However, Enfield seems to have done the trials rifle rivets by hand, no huge surprise given the cost of fabricating dedicated tooling.

BTW the rivets are AN450 tailed types but w/ flat or cheese heads as opposed to the usual AN671 heads.

Last edited by jmoore; 07-08-2011 at 08:15 AM.

Reason: pics

-

-

-

-

We had rivets and a special tool for these at our bigger workshops. The rivets that we had were all flat head, hollowed/tubular at the rivetted end. They came from a company in Aylesbury. The two rivetting machines were

1) the simple support the rivet and use a dolly to turn the rivet over as shown in JM's aircraft set. The ham-fisted among us would crush the wood until you got used to it. And

2) one a more 'complicated' (until you'd used it a few times) rivetter that lived in the sheet metal workshop that spun the rivetting dolly that formed a perfectly rounded tail as shown on AdeE's and JM's photos. This was better because you couldn't crush the handguards.

I seem to recall that while the rivets were available, they were always 'dues-out' meaning that you'd wait ages for them. There was a general G1 or G2 number for a similar rivet that we used instead. Being 'dues-out' meant a good excuse to berate the blanket stackers (the storeman) for being crap at his job and not keeping on top of things or just, well, being a crap storeman was usually good enough

-

Thank You to Peter Laidler For This Useful Post:

-

Contributing Member

And there I was just thinking that JM was trying to stir the forum up a bit, all those blank spots were just memory lapses, happens when you get old.

So now I'm stuck here looking at bloody rivets in different woodwork, I even had a look at the oppositions rifles to see how they did theirs, maybe the Krauts were a bit more uniform.

-

Information

Information

PM

PM

If you find some solids on yours -or tubular rivets on a Savage- please note the ID marks on the metal cap and on the wood (probably hidden underneath) and throw the info on here. Also, please note whether the wood in the cutout area was relieved for thr hinged forward band.

If you find some solids on yours -or tubular rivets on a Savage- please note the ID marks on the metal cap and on the wood (probably hidden underneath) and throw the info on here. Also, please note whether the wood in the cutout area was relieved for thr hinged forward band.