-

Question about the plunger on the No1Mk3 (and: another refurbed)

Hi everyone,

While I refurbed this rifle: Refurbed No1Mk3* - Military Surplus Collectors Forums

A question occurred to me. On the No1Mk3, in the forend near the muzzle, there is a plunger with a spring. This plunger rests on the nose cap, and pushes upwards on the barrel. Doesn't this tend to make the barrel muzzle "want" to contact the top side of the hole through which it protrudes aat the front of the nose cap? I can't figure out the dynamics involved.

Lou

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

-

02-07-2010 07:34 AM

# ADS

Friends and Sponsors

-

Advisory Panel

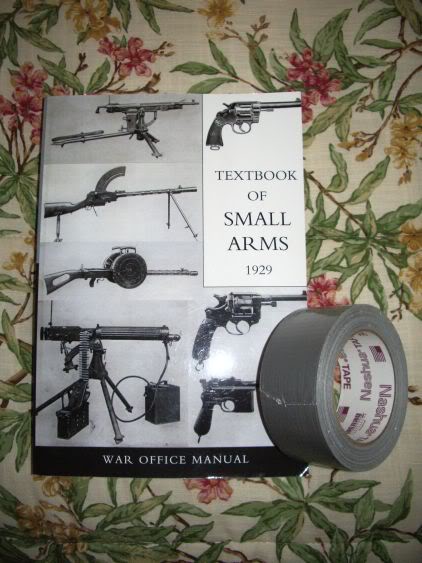

Reading "Textbook of Small Arms, 1929" might prove enlightening. In short as a bullet moves down the barrel, the barrel vibrates and the muzzle moves in different directions. If uncontrolled, the bullet hits the target at different points due to the changes in position of the muzzle. The forestock spring loaded bearing point was a means of insuring that the muzzle/ barrel would be in the same position for each shot.

-

-

-

Banned

-

Advisory Panel

Originally Posted by

louthepou

Hi everyone,

While I refurbed this rifle:

Refurbed No1Mk3* - Military Surplus Collectors Forums

A question occurred to me. On the No1Mk3, in the forend near the muzzle, there is a plunger with a spring. This plunger rests on the nose cap, and pushes upwards on the barrel. Doesn't this tend to make the barrel muzzle "want" to contact the top side of the hole through which it protrudes aat the front of the nose cap? I can't figure out the dynamics involved.

Lou

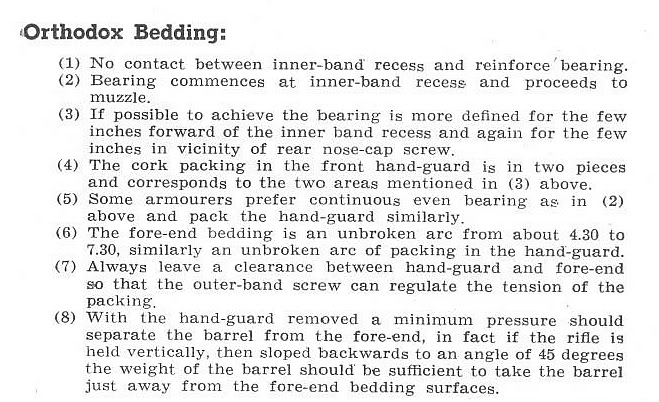

Yes, the nosecap actually pulls the barrel back down again, in a correctly set up No1. There should be a tiny gap at the bottom of the aperture in the nosecap where the barrel protrudes.

When (c.1900) they chopped off the barrel of the Long Lee and lightened it for the future "short" rifle, they obviously ended up with a host of accuracy problems relating to bedding and barrel vibration - that was fairly new knowledge in those days, given that most preceding rifles had been fully stocked and bedded. The SMLE's complicated bands, springs & bedding points all appear to be fixes derived from trial-and-error. If WW1 hadn't come along and forced production of millions of No1s, I imagine they would have fairly quickly moved to a heavy-barrel No1 with much simpler bedding - an earlier version of the No1 MkVI and No4.

-

-

FREE MEMBER

NO Posting or PM's Allowed

Or perhaps a P13 Mk.?, Thunderbox.

Brad

-

Thanks guys, quite helpful.

Ed, therefore I'll have to find some way to do without the duct tape on my recently acquired, number-matching Lithgow .

.

-

-

Banned

-

Phew, I'm glad that someone else answered that! As apprentices, the lessons on harmonics, vibration and all the other properties of hollow tubes lasted an age so I learned it all parrot fashion. Later in more advanced mech eng. theory, this stood me in good stead because I could still quote it parrot fashion!

-

-

Advisory Panel

Phew, I'm glad that someone else answered that! As apprentices, the lessons on harmonics, vibration and all the other properties of hollow tubes lasted an age so I learned it all parrot fashion. Later in more advanced mech eng. theory, this stood me in good stead because I could still quote it parrot fashion!

Peter you learned it on the job, I had it in Engineering School and later had to acually use it in trying to calm down vehicle steering wheels and steering column shake in four cylinder cars at idle with the air conditioning one. Engineering is engineering no matter what the use.

-

-

Banned

Phew, I'm glad that someone else answered that! As apprentices, the lessons on harmonics, vibration and all the other properties of hollow tubes lasted an age so I learned it all parrot fashion. Later in more advanced mech eng. theory, this stood me in good stead because I could still quote it parrot fashion!

Mr. Laidler

Harmonics in hollow tubes is all about up pressure and Viagra.

PM

PM