-

Contributing Member

No5 MkI legends, truths or bs?

I bought a 1945 BSA No5 MkI recently. Its in excellent shape, aside from a mismatched bolt and stock, but its a perfect shooter.

The seller told me a few stories on it. He said that it was issued in Malaysia and that's why the fore end has varnish on it, and that they often removed the fore end cap and rounded the wood there, like a sporter. Any truth to this?

The fore end looks super dry and has twisted, so if it wasn't done in service I want to strip it and give it a good soaking in RLO before I try to fix the fore end so it doesn't make contact with the side of the barrel. Kind of hoping its just drier than a popcorn fart and has twisted from it. Front band is loose too so I hope things swell up and go back how they should be.

I can post pics tonight.

Thanks

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

-

09-04-2012 04:06 PM

# ADS

Friends and Sponsors

-

Legacy Member

Use raw linseed oil instead, that is the correct stock treatment, after removing any other stock treatment.

instead, that is the correct stock treatment, after removing any other stock treatment.

-

-

-

Advisory Panel

FMP (Federal Malaysian Police) stamped on the left side socket would be a strong indicator of Far Eastern service. Lack of the marking does not rule it out either. Britain sent a number to the police during the Malayan Emergency.

sent a number to the police during the Malayan Emergency.

-

-

Contributing Member

Even if it was there is this finish and fore end something that would have been done in service or has someone else had a turn since?

-

-

Legacy Member

No5 MkI legends, truths or bs?

-

-

Contributing Member

Thank you. Pics up shortly

-

-

Contributing Member

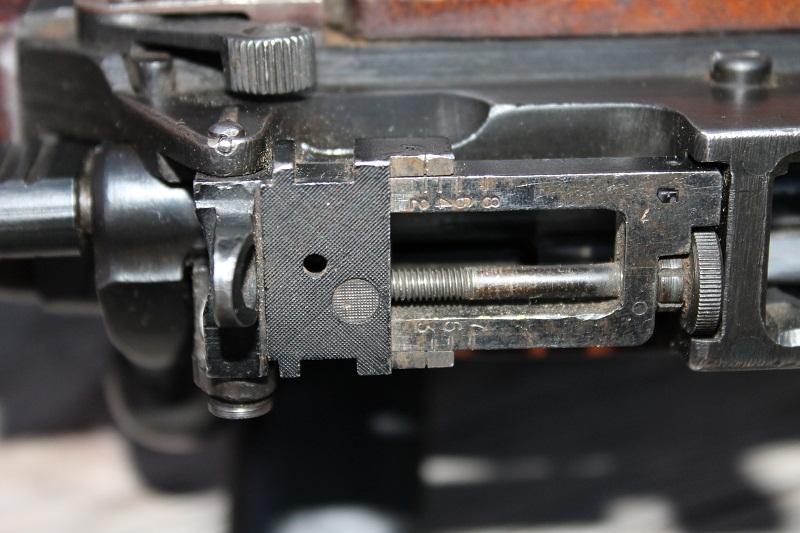

-

-

FREE MEMBER

NO Posting or PM's Allowed

looks pretty good, I'd be happy with that... re truth, when they had metal caps on the front of the forend they were prone to corrosion inside and the caps were sometimes removed and the wood rounded Varnish I don't know, could be anything, incl after service or something just done on the day, it doesn't sound official tho.

Last edited by RJW NZ; 09-05-2012 at 02:21 AM.

-

None of our rifles were ever varnished, ever......... Just try holding a varnished rifle in the rain - of which Malaya in general is well known for. A goodly dose of linseed might help with the warped fore-end but it will not cure it. Dunk the whole thing in very warm to touch oil and let it soak for several hours. Don't think of varnish keeping the weather OUT, think of it as a medium for keeping the wet IN which isn't quite what you want!

When there was any sign of rust or corrosion, and there was inevitably some, believe me...., we would drift out the fore-end cap rivet (I seem to remember that they were brass on the No5... correct me if I'm wrong after all these years) and make good the end of the wood. Then, importantly, glue and plug the rivet hole, make good and then round the end to suit. Then dip fore-end in linseed for several hours. Done hundreds of themPolice, para military Police and Army, from right across the Far East, they all came through the same big UK workshops

workshops

-

The Following 3 Members Say Thank You to Peter Laidler For This Useful Post:

-

Advisory Panel

Here in Mauserland that would be a good find. London civilian proof marks on the barrel (so no problem with using it as a shooter) but the bayonet boss has been retained (here, nearly all have been removed as part of the "demilitarization" procedure). Barrel bluing looks remarkably good for the age. Hang on a mo - weren't they originally finished with Suncorite? So maybe it was refinished in civilian life.

One addition to what Peter wrote. Dunk in linseed oil for several hours - yes. But if you have not got a handy oil tank, or so much oil, just paint the the oil on inside and out, and leave for days, rather than hours.

for several hours - yes. But if you have not got a handy oil tank, or so much oil, just paint the the oil on inside and out, and leave for days, rather than hours.

If you can, forget it for a week or two. Because even if you have removed any varnish on the surface, the pores of the wood will still be fairly clogged up compared with factory-fresh wood, and the oil penetration is thus reduced. General motto: go slowly with old wood, and repeat the oiling until you are satisfied that it is not taking up any more. It may have taken half a century to dry out and warp - do not expect it to return to its original form in half a day - if ever! And for improved initial wood penetration, add a little natural turpentine to the oil. This also fires up the grain so pleasingly that it encourages you to persevere!

Last edited by Patrick Chadwick; 09-05-2012 at 05:06 AM.

-

The Following 2 Members Say Thank You to Patrick Chadwick For This Useful Post:

PM

PM