-

Legacy Member

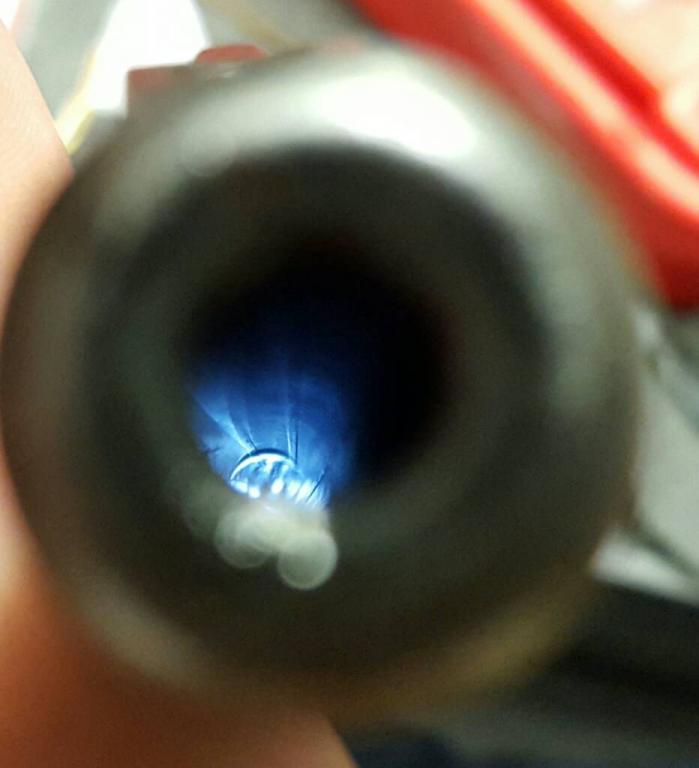

Bore condition and photographs

Last edited by Sentryduty; 03-11-2016 at 11:49 AM.

- Darren

1 PL West Nova Scotia Regiment 2000-2003

1 BN Princess Patricia's Canadian Light Infantry 2003-2013

-

Thank You to Sentryduty For This Useful Post:

-

03-02-2016 05:07 PM

# ADS

Friends and Sponsors

-

Legacy Member

-

-

-

Legacy Member

I am not precisely sure, could be a rifling defect from the factory, could be a place where the front sight screw holes nearly broke through into the bore when they were drilled, or some other weird damage that happened before it came into my family's hands.

Checking my shooting log, the best 3 shot group this rifle would turn out was just under 1" @ 25m, so about 4 MOA, it is literally the worst grouping .22 I have ever shot, including some Norinco stuff.

I thought it was unusual at the time but all these years later I think I have a good indicator why.

Last edited by Sentryduty; 03-11-2016 at 11:49 AM.

- Darren

1 PL West Nova Scotia Regiment 2000-2003

1 BN Princess Patricia's Canadian Light Infantry 2003-2013

-

-

FREE MEMBER

NO Posting or PM's Allowed

looks like an oil ring to me. Common in .22's.

-

Legacy Member

It's not a bulge but a projection?

-

-

Legacy Member

Originally Posted by

martins8589

ooks like an oil ring to me. Common in .22's

Please explain what an "oil ring" is. That is a new term to me.

The interaction between barrel condition and accuracy is quite a mystery to me.

Ed reluctantly no longer in the Bitterroot

-

-

Legacy Member

Originally Posted by

WarPig1976

It's not a bulge but a projection?

The is correct, I spent a fair bit of time squinting down this tube, expecting to find a ring, but it is only this little crescent at the top of the rifling, everything else is fine. It does project into the bore and is probably swaging the bullets down as it passes this portion.

I did some reading that apparently the barrels are easily removable from this action with a single screw. That being the case, I may just slug the bore with a lead .22 projectile and see what it looks like after a trip through the barrel.

- Darren

1 PL West Nova Scotia Regiment 2000-2003

1 BN Princess Patricia's Canadian Light Infantry 2003-2013

-

Thank You to Sentryduty For This Useful Post:

-

Legacy Member

Ahh, a little JB bore paste some super glue and a big hammer, should clean right up.

-

-

Legacy Member

Well, I did have the thought that this might be some extreme case of localized leading of the bore, but really I cannot imagine any good reason for a leading issue to build like this. Since you fellows have the interest, I will look at this a bit further.

Updates will be pending.

- Darren

1 PL West Nova Scotia Regiment 2000-2003

1 BN Princess Patricia's Canadian Light Infantry 2003-2013

-

-

Advisory Panel

First of all, try to soften up the obstruction by moving a swab soaked in acetone up and down around the affected section. If this does not remove the protrusion, may I suggest that you then try the method I used (very successfully!) on the Hannover "Pickelgewehr".

https://www.milsurps.com/showthread.php?t=49231

(Post 7 in the thread)

The trick is a brass slug turned to a close fit in the bore, with a thin ring (about 1mm) of groove diameter left projecting as a driving band. And the slug is then indeed driven down the barrel as described in the link. If the protruding ring is a) some kind of fossilized gunk, this method will get it out without damaging the bore.

It ought to work. The protrusion seems to be too symmetrical and smooth to be either b) a near-breakthrough of a drilled hole, or c) a rust blister.

a) should be cleared.

b) is probably a hopeless case for table-top methods, as the slug will not shear off barrel metal.

c) may be broken up, leaving rust pits. but will afterwards require a lot of shoot/clean shoot/clean sessions to smooth down rough edges.

The slug should be of hard brass or even bronze, but not, of course, steel!

A countersunk brass screw of suitable diameter might work, the countersunk head providing the "driving band".

I'm guessing (hoping?) that it is indeed a) fossilized gunk, as it looks like the residue one would see if a well-meaning person oiled the bore heavily, and then left the rifle lying on its side for a few years, while the oil collected at the lower side of the barrel and then gradually dried out.

Give it a try, and good luck!

Last edited by Patrick Chadwick; 03-03-2016 at 03:05 PM.

Reason: ...thin ring (about 1mm) of groove diameter...

-

Thank You to Patrick Chadwick For This Useful Post:

PM

PM