Note: After you click on images to ENLARGE them, you may find they automatically size smaller in your browser's window making them harder to view. The auto sizing is your browser's way of keeping images entirely within the screen size you have set. Move your mouse pointer to the bottom centre of the pic and you will see an options panel appear. There will be a small square box next to the large X, which will have a pointer arrow sticking out of it. If it's illuminated, it means the pic you're viewing can be enlarged, so click on this box and the pic will EXPAND and open to its normal size.

Fore Sight Adjusting Cramps

by Graeme "broadarrow303" Barber

by Graeme "broadarrow303" Barber

If you have collected a military firearm perhaps you too will have experienced the euphoria created by admiring it, reading about it and showing it off to others who are willing to share the passion. This is very often followed (invariably soon after acquisition) by the desire to purchase accessories, tools and any other item that was used with or for its continuance in service. Most extra items are readily available and reasonably priced and can keep the interest alive before another firearm for the collection is sourced. Most collectors acquire extras such as bayonets, slings, ammo pouches, manuals, cleaning gear, armourers tools or any other accessory they manage to lay their hands on.

While many of the extra items were issued with the firearm as part of a soldiers fighting kit there were some that were used by armourers and intended for more specialised functions. Foresight adjusting cramps are one example of such items but little seems to have been written about them.

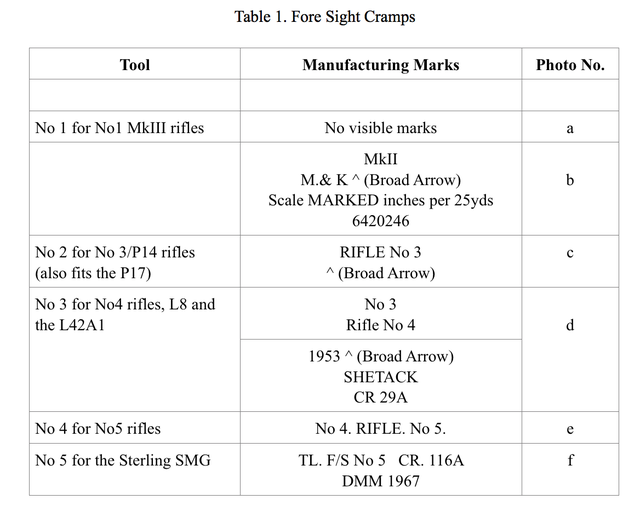

This article is about six cramps from the author’s collection. The numbering system is intriguing, as it seems to be consecutive probably based on the production order of the firearms. The following table identifies the tool number and firearm it fits, and marks on examples in the photographs.

Table 1. Fore Sight Cramps

The No 1, No 4 and No 5 tools were milled out of a solid block of steel with the No 4 tool requiring several intricate cuts to fit around the bayonet lug on the No 5 ‘Jungle Carbine’ rifle. The No 2 and No 3 tools were fabricated from flat steel with the parts for the No 2 tool very crudely cut and welded together. While looking very similar tool No 2 is too narrow to fit over the No 4 rifles fore sight protectors ears. The No 3 tool is however able to function effectively on the P14 rifle.

An occasional photo and caption relating to tools No 1 and No 3 can be found in the informative Skennerton and Labudda publications on the Lee-Enfields and a few websites also provide photos that serve to identify some of the cramps. More precise information about these tools and how to use them is limited to military armourers pamphlets. Tools No 1 (Marks I and II) and No 3 surface from time to time in auction catalogues and on web based auction sites. Tool No 2 is reasonable scarce. Tools No 4 and No 5 are extremely hard to find probably once again a direct correlation to production numbers of the firearms.

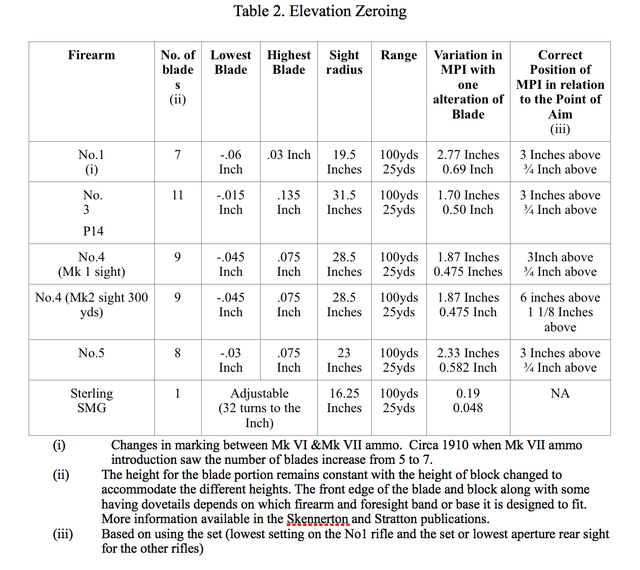

The cramps were essentially designed and manufactured to facilitate the adjustment or exchange of a foresight blade as part of the “zeroing” process. The foresight blades were manufactured in varying heights so any vertical error could be corrected by replacing the existing blade with one of a different height. The blades were either above or below the 0 stamped blade by multiples of .015inch. The tip of the 0 blade when fitted in to a dovetailed base on the firearm was exactly 1 inch above the axis of the bore. All blades were stamped - those below the zero with a minus prefix.

Table 2. Elevation Zeroing

To calculate the difference a change in foresight would make at the target in relation to the point of aim use the following formulae (in Inches).

(Range x Difference in Height of blades) divided by sight radius = variation on target

Alternatively to calculate the correct foresight blade to fit to a rifle to achieve zero use the following formulae (in Inches).

(Sight radius x the height of the group MPI -usually 5 shots- above or below the point of aim) divided by range length = the change in height of fore sight needed

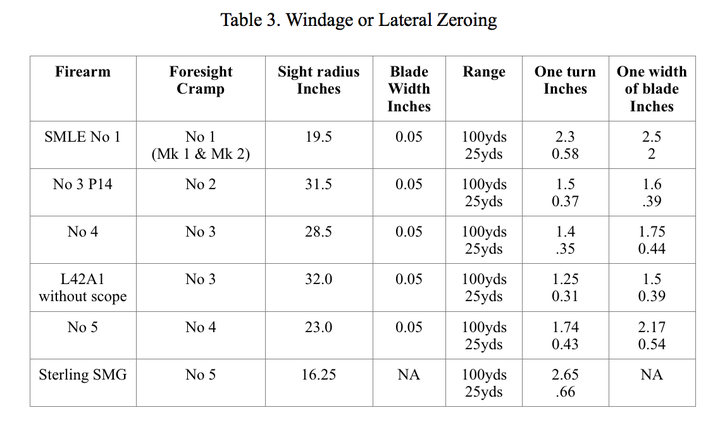

Table 3. Windage or Lateral Zeroing

The following thread measurements were taken from the foresight cramps in the author’s collection (may vary for different manufacturers). Foresight cramp No 1 (Mk 1 and Mk 2) has 22 threads per Inch (1/22) which equals .045 Inch. Foresight cramp No 2 has 21 threads per Inch (1/21) which equals .047 Inch. Foresight cramps Nos 3 & 4 have 25 threads per Inch (1/25) which equals .04 Inch. Foresight cramp No 5 has 23 threads per inch (1/23) which equals .043 Inch.

To calculate the impact of lateral adjustments using the foresight cramp the following formulae (in Inches) should be used.

(One complete turn of the screw cramp x Range) divided by sighting radius then x10 = the lateral adjustment

The front of the foresight base was centre punch mark to provide a reference point (zero mark) for the new blade before the old blade was removed. T bar screws on the cramp were wound out far enough to enable the fore sight blade to lie between the screws. The screws were tightened until the foresight blade was gripped gently then one screw was unscrewed and the other tightened alternately until the foresight blade was removed without damaging the foresight base. The replacement foresight blade was correctly positioned back to the zero position using the T bar screws to push and guide it back in to place. Once the foresight blade was correctly located it was centre punched to lock it in place. The early and first variation of the No4 rifle foresight base was fitted with a foresight blade screw that negated the need for the blade to be secured with a centre punch.

The No1 tool by its design necessitated the removal of the SMLE nose cap in order to slip over the foresight base (refer photo b). The nose cap was replaced once the new blade was correctly positioned. If adjustment or replacement of the foresight blade was required after any test firing the nose cap needed to be removed once again. The design of tools No’s 2-5 were improved significantly as they fitted over the foresight protector and could remain in place after a foresight blade was replaced and during any test firing and subsequent adjustment.

Some tools can be found without military marks suggesting that the trade produced and sold cramps to the serious target shooter as well to be used to improve the accuracy of the many sold out of service firearms that saw extensive use within the target shooting fraternity long after their service life had finished.

Most armourers however reported that they rarely if ever used an adjusting cramp instead finding a hammer and drift much quicker and more efficient to the deft touch of a soldier trained in the art of keeping firearms functional and accurate for the front line soldier.

Tool No 1 Mark I for SMLE rifles (Authors collection)

(Click PIC to Enlarge)

Tool No 1 Mark II fitted to a SMLE rifle (Authors collection)

Tool No 2 fitted to a P14 (No 3) rifle (Authors collection)

Tool No 3 fitted to a No 4 rifle (Authors collection)

Tool No 4 fitted to a No 5 jungle carbine (Authors collection)

Tool No 5 fitted to a Sterling SMG (Authors collection)

References

Skennerton I.D., The Lee Enfield A century of Lee-Metford & Lee-Enfield Rifles & Carbines, Skennerton Publications, 2007.

Labudda B. & Skennerton I.D., Accurizing & Shooting Lee-Enfields, Skennerton Publications, 2005.

Small Arms Part 3 Instructions for Dismantling, Assembling, Testing, Adjusting, Lubricating, Maintenance, and Repair, A.P.1641P, Air Ministry 1943.

Stratton C.R., British Enfield Rifles Volumes 1, 2,4, North Cape Publications, 1997-2000.

Skennerton I.D., The Lee Enfield A century of Lee-Metford & Lee-Enfield Rifles & Carbines, Skennerton Publications, 2007.

Labudda B. & Skennerton I.D., Accurizing & Shooting Lee-Enfields, Skennerton Publications, 2005.

Small Arms Part 3 Instructions for Dismantling, Assembling, Testing, Adjusting, Lubricating, Maintenance, and Repair, A.P.1641P, Air Ministry 1943.

Stratton C.R., British Enfield Rifles Volumes 1, 2,4, North Cape Publications, 1997-2000.

Collector's Comments and Feedback:

Countries

Countries Categories

Categories Recent Article Comments

Recent Article Comments