-

Mysteries of the 'A' Suffix

Mysteries of the 'A' Suffix

I’d like to take a sub-thread of x-westies thread (?) a bit further where comments about the A serial number suffix arise. We all know by now that the A suffix indicates a ‘weapon of any description which bear the suffix letter A to the serial number…… blah blah and so on…………..’ indicates that component parts are not interchangeable. We know that this first arose with the trials and pre-production rifles that entered service and later, according to Small Arms Instructions (called, SAI’s for short….) that this also applied across the board, to ALL rifles so marked. It was an important feature in the Armourers world because it applied to Brens and Stens too. Very few Brens but certainly Stens and No4’s and another that we had to look out for was the 3.5” rocket launcher. But I digress.

I had an opportunity to speak to one of the now very old ex Carlisle Armourer instructors for an hour on the phone the other day and I mentioned this subject. And he made a couple of valid points. Incidentally, he was one of those who wrote/drafted the first original EMER’s relating to the No4, taking it away from the older Instructions for Armourers. He said that these A marked rifles were inevitably marked at the factory (but not necessarily so…) where they could not be assembled by the unskilled labourrers for a couple of reasons. The first was within the time frame allowed as they were all on ‘piece’ work (as opposed to ‘peace’ work!) and the second, they couldn’t be assembled using the parts that were supplied. That makes perfect sense so far.

As a result of this, such rifles were diverted to a rectification bay where more experienced, but not necessarily ‘skilled’ workers would attempt to assemble them using whatever means they had at their disposal. This included ring punching oversize holes, clearing out threads etc etc. As a result, THESE rifles were marked with the A suffix on instruction of the Supt of Design and the MoS PLUS the IA (the Inspector or Armourers) because these rifles would inevitable pass through their hands. It was for this reason that the message went out in the speedy Small Arms Instructions.

Another very interesting point is this, that hadn’t crossed my mind was that you will never (? – although I have never looked or noticed) see an A suffix on a BSA or Savage rifle. That’s because they were private companies, making and selling their wares to the Ministry of Supply/Government and if the quality wasn’t good enough or there were faults, then they wouldn’t buy and certainly wouldn’t pay for shoddy goods! I know that later the Savage contracts were taken out of the MoS frame as lend-lease, but…………

There, there’s another little bit of useless Lee Enfield bumph that neither you nor I really knew about.

Not strictly related to this thread is an end-on picture of an instructional barrel section from the Shrivenham technical collection. I can’t tell you any more but the label reads ‘.303” No4, 7”+’. The thickness would indicate a 4” section of barrel from 7 to 11”

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

The Following 16 Members Say Thank You to Peter Laidler For This Useful Post:

Alan de Enfield,

Badger,

Beerhunter,

bradtx,

Brian Dick,

jmoore,

limpetmine,

madcratebuilder,

No4Mk1(T),

Roger Payne,

Son,

Strangely Brown,

Surpmil,

tbonesmith,

Terry Hawker,

tlvaughn

-

01-10-2010 06:55 PM

# ADS

Friends and Sponsors

-

Advisory Panel

Perhaps the perspective is fooling me, but it looks like somebody's aim wasn't the best the day they drilled that barrel.

Very interesting info on the A suffix Peter. I hope you or someone else will be able to 'pick the brain' of that armourer and any of his colleagues of similar vintage who are still with us.

One has the feeling there is so much more information in minds like his that is still not recorded...

-

-

Banned

Originally Posted by

Surpmil

Perhaps the perspective is fooling me, but it looks like somebody's aim wasn't the best the day they drilled that barrel.

Very interesting info on the A suffix Peter. I hope you or someone else will be able to 'pick the brain' of that armourer and any of his colleagues of similar vintage who are still with us.

One has the feeling there is so much more information in minds like his that is still not recorded...

If you would try and save the photo you would see the photo is labeled “eccentric%20barrel%20009.jpg”

eccentric barrel: (of an axis.) not situated in the center.

As an ex-inspector we had a saying “you have to look at the back, belly and both sides.”

Signed

Ed Horton

Eccentric Inspector

Last edited by Edward Horton; 01-10-2010 at 11:31 PM.

-

You would be suprised to see how much non cold hammer forged barrel bores wander. Most barrels are turned on centers after the deep hole drilling is done so that at least the front and back ends run reasonably true. The best barrels TEND to have less wander, but its a major reason that groups "wander" )esp. in lightweights) as things warm up.

Gee, this thread got off topic quick!

-

The Following 2 Members Say Thank You to jmoore For This Useful Post:

-

You're all correct of course. I forgot to add that this barrel has been drilled, finished and welll used in service and has gone eccentric over the course of its length, probably due to hardness problems or impurities in the steel mix.

Going off at a tangent (me that is, as opposed to the hole in the barrel.....), the breech end MUST have been concentric because if it was this eccentric, the striker would miss (? possibly) the cartridge anvil and at the muzzle, an inspector would/should pick it up as eccentric.

But as all engineers know, bringing an ecentric hole back true is a dodgy game. This 2 groove barrel was used to show that if the last 6" were straight then the barrel would reasonably group

-

-

FREE MEMBER

NO Posting or PM's Allowed

Peter, I certainly don't disagree with you, but (you saw that coming) in the case of Fazakerley there seems to have been an 'executive/political/CYA' decision made with regards to stamping the A suffix. Every wartime produced Fazakerley, excepting a couple of very early examples, I've seen has an A suffix. Every A suffix rifle had one or more war expediant part installed.

Brad

-

Advisory Panel

I had a conversation a few years ago with a Lithgow trained barrel straightener. If I remember correctly, he said the bore was completed before the final sizing of the OD. Any that did not drill straight were straightened to the bore so finish cutting the OD would make them concentric- avoiding accuracy problems as the barrel heated up with firing as jmoore intimated.

trained barrel straightener. If I remember correctly, he said the bore was completed before the final sizing of the OD. Any that did not drill straight were straightened to the bore so finish cutting the OD would make them concentric- avoiding accuracy problems as the barrel heated up with firing as jmoore intimated.

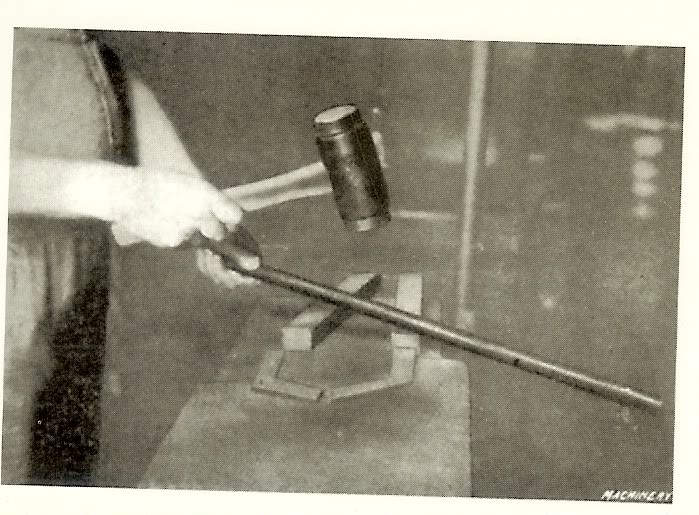

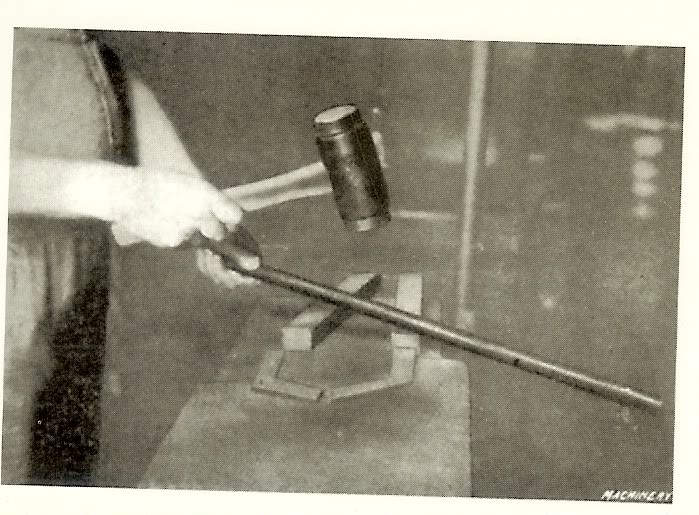

The method was to "read" the barrel by shading (a technique still taught today for the purpose of inspecting for bent, bulged, puckered or ringed barrels) The barrel was then held at one end, rested on the "anvil" at the other, and given a "measured" blow with the soft faced hammer somewhere in between.

The long retired factory hand said only about one in a hundred that tried the job ever got past the first day. You either got it straight away or you never would. The "knack" involved knowing from one look, where to hold it, rest it, hit it and how hard. After a couple of hits, if it wasn't right it was scrapped.

I tried straightening a barrel once (LSA)- for about three days! I finally got it right, fitted it and tried it out. It didn't stay straight....

On the topic of barrel manufacturing, I read a piece by a particular "widely revered" gun guru where he said he'd spent time in England ......

......

"Years ago I had a chance to spend some time in England. I met a fellow who was a British Army Armorer. He and I talked over beers about rifles and all sorts of WWI and WWII weapons in general. I brought up the topic of head spacing in the Enfield Rifles . He told me that they were taught to " To provide enough head spacing as to allow the soldier to carry a dry pair of socks" in these rifles. The reason being war time production of ammunition and the very different climates these rifles were to be used in. I asked him how they adjusted the head spacing, did they use the numbered bolt heads for the No4 rifles, or the varying length No1 type bolt heads to adjust the head spacing?. If they could get them,yes. But the number they needed was not always available out in the field. 95% of the time the bolt body was shortened or replaced from another rifle being used for parts."

. He told me that they were taught to " To provide enough head spacing as to allow the soldier to carry a dry pair of socks" in these rifles. The reason being war time production of ammunition and the very different climates these rifles were to be used in. I asked him how they adjusted the head spacing, did they use the numbered bolt heads for the No4 rifles, or the varying length No1 type bolt heads to adjust the head spacing?. If they could get them,yes. But the number they needed was not always available out in the field. 95% of the time the bolt body was shortened or replaced from another rifle being used for parts."

Another part from earlier in his post...

".303 Military brass has a very thick web in the casing which when fired in an Enfield rifle with excessive head spacing may not show any signs of case stretching. When the shooter tries a commercial loaded round and sees a bright band or an " hour glass" shape just in front of the rim, they assume that the brass is somehow faulty. Not true. It is your rifle. Any time you see a stretch mark or the case fails and parts in two just in front of the rim, its caused by excessive play. 8 of of 10 ten times it is excessive head spacing. The other causes are a too long chamber where the case is " blown out" to fill the shoulder area, or the chamber is out of round, drilled off center. Beleave it or not, this is not uncommon with these rifles. You gather up 10 Enfields and you will see fired cases from a couple of these rifles that show and off center / out of round chamber."

I offer this for comment, isn't it more likely that all the problems seen or imagined by this person were caused by undersized "SAAMI spec" brass sitting in the bottom of the chamber with a slight gap above?

If this has gone too far off Peters original post (pic of barrel segment...?) then please delete.

-

-

Legacy Member

Had a good book (for Christmas) on the subject of making rifle barrels. There are 62 pages devoted to Enfield barrels and it goes into great detail about straightening them.

Heavy reading for a non-engineer, but interesting non the less

ISBN 1-55918-280-6

Extract :

"The straightening of the barrels is conceded to require the greatest of skill of any operation in the manufacture of rifle barrels. As the writer of this article spent nearly a third of a century in the occupation of straightening barrels, and as there has probably never been a comprehensive article written on this subject before, the operation will be treated exhaustively here in the hope that a real understanding of the method of rifle barrel straightening may be conveyed to the minds of the readers. ........."

"...... In straightening a rifle barrel, the three important tools required are a shade, a straightening block and a hammer ..............."

-

The Following 2 Members Say Thank You to Alan de Enfield For This Useful Post:

-

Shortening the bolt body to accommodate CHS............ Surely...... From the bolt head end, you wouldn't achieve anything because it's threaded.... And shortening it at the bolt head end would just increase the gap between the cocking piece and the rear face of the bolt. And reducing the length of the locking shoulders would just INCREASE CHS.......... Have I got something wrong.

The moral of the story is don't believe an Armourer....unless he's been an Australian Armourer too!

Armourer too!

-

-

Advisory Panel

-

PM

PM