-

Originally Posted by

Patrick Chadwick

DON'T TRY IT

I have not yet succeeded in finding anything resembling standards for the .43 Spanish chambering. Any drawings that may exist could only be taken as guidelines.

The bore should be somewhere in the region 0.410" to 0.430" mm, and although the grooves are much deeper than for modern calibers, you have to recognize that this is nearer to a 44 than a 45. You would not try to drive a 45 bullet through a 44 barrel.

The groove diameter will be somewhere around 0.440" - 0.450". Modern handgun bullets are far too hard to be driven through a bore by hand, unless you use the kind of force that is going to be hazardous for your barrel. It will not be feasible to get the degree of upset/obturation/bump-up - call it what you will - that is required to fill those deep grooves.

YOU MUST USE A SOFT LEAD BALL OR BULLET if you want to get the groove depth.

A 429-430 lead bullet might go, but that would only give you the bore diameter, not the groove diameter. OK - that would be better than zero information, which is our present state of knowledge! But if a 429 bullet will not go down with the brass rod method, give it up and knock the bullet out again.

I think the first step is just to roughly measure the groove dia. with a pair of calipers at the muzzle if it's not altogether bell mouthed.

Contrary to Patrick Chadwick, I'm thinking those above bullets may just work.

I believe those Speer bullets are swaged, not cast and are dead soft. So if your bore (grooves) runs 0.447"+ then I think it'll work fine. Just start it w/ a large hunk of nylon or delrin, IF they are the swaged type. I've done similar plenty of times w/ no ill results.

One COULD also reduce the diameter of the rear of a test bullet to reduce the bearing surface. Stupidly, if you have a lathe available w/ collets, just squeeze the back end a bit. Almost no force would be required!

-

-

12-04-2010 03:51 PM

# ADS

Friends and Sponsors

-

Another idea is to get some similarly sized fishing lures or other soft lead plug and a piece of steel flat bar. On a solid surface like a tile floor or a piece of sheet steel, roll the plug under the bar while putting pressure on it. Measure often - it will elongate and the diameter will shrink. When you get within 5 or 10 thou of the calliper measure groove depth, stop. You now have an appropriate slug.

Союз нерушимый республик свободных Сплотила навеки Великая Русь. Да здравствует созданный волей народов Единый, могучий Советский Союз!

-

Thank You to Claven2 For This Useful Post:

-

-

FREE MEMBER

NO Posting or PM's Allowed

-

Advisory Panel

A photography tip

Originally Posted by

jmoore

the muzzle if it's not altogether bell mouthed.

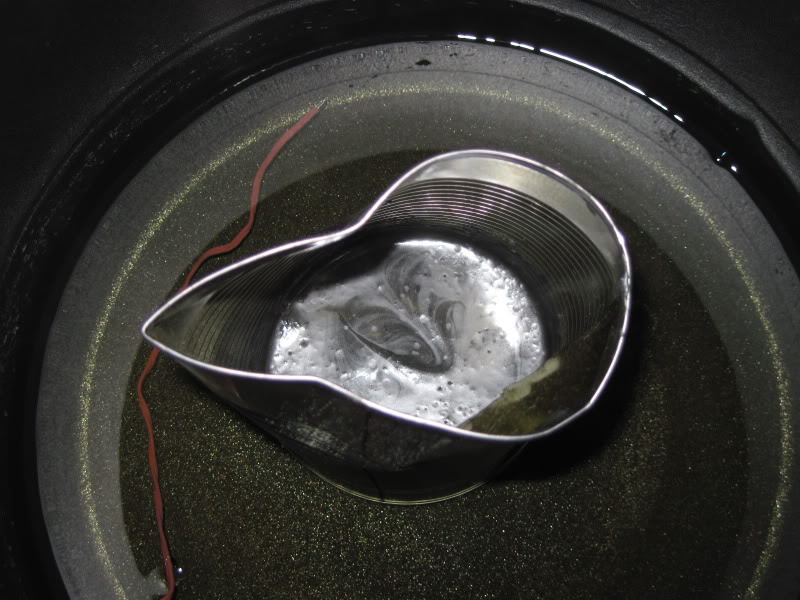

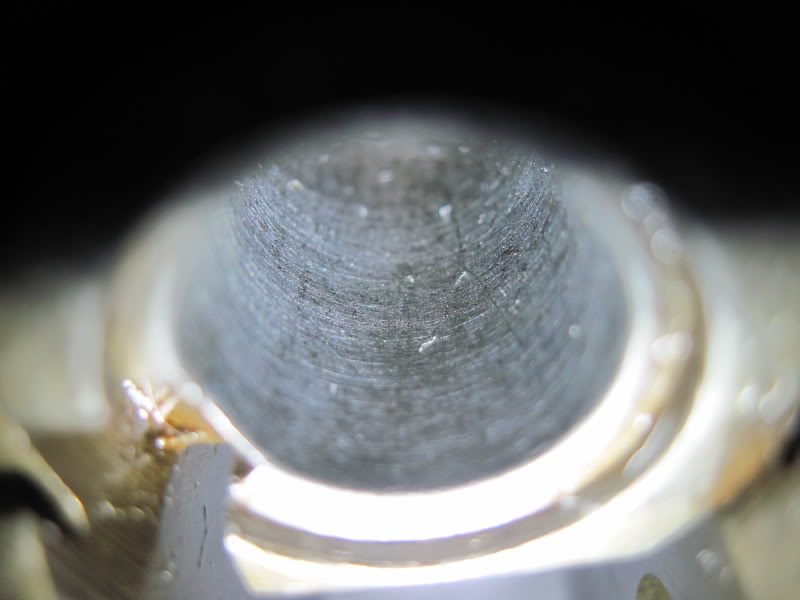

I think we would all find it useful to have a pic of the muzzle end of the rifling now.

You previously posted pics of the throat end. They came out very well, because the chamber was in shade. so you could focus on the throat, which is lit up better than the surroundings.

However, at the muzzle end it is the other way around - the bright surroundings of the crown and background make it impossible to get a good photo of the vital last half-inch of the rifling.

Use a piece of plastic pipe, cardboard tube etc to make a hood for the muzzle, and then you can focus a camera on the rifling, which will then be brighter than its surroundings.

Last edited by Patrick Chadwick; 12-05-2010 at 01:47 PM.

-

Thank You to Patrick Chadwick For This Useful Post:

-

FREE MEMBER

NO Posting or PM's Allowed

Originally Posted by

jmoore

I think the first step is just to roughly measure the groove dia. with a pair of calipers at the muzzle if it's not altogether bell mouthed.

Contrary to Patrick Chadwick, I'm thinking those above bullets may just work.

I believe those Speer bullets are swaged, not cast and are dead soft. So if your bore (grooves) runs 0.447"+ then I think it'll work fine. Just start it w/ a large hunk of nylon or delrin, IF they are the swaged type. I've done similar plenty of times w/ no ill results.

One COULD also reduce the diameter of the rear of a test bullet to reduce the bearing surface. Stupidly, if you have a lathe available w/ collets, just squeeze the back end a bit. Almost no force would be required!

I have some 44cal lead bullets that would work except that they are hard cast for my 44mag.

-

Advisory Panel

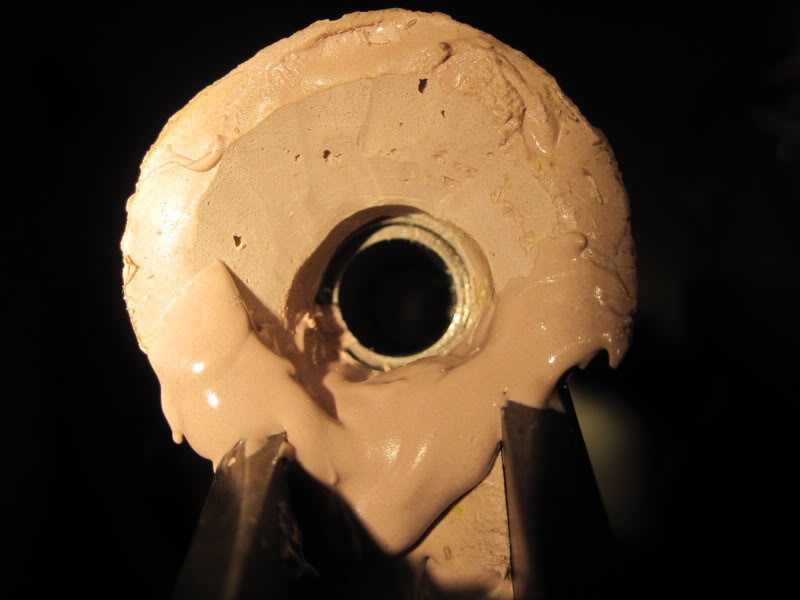

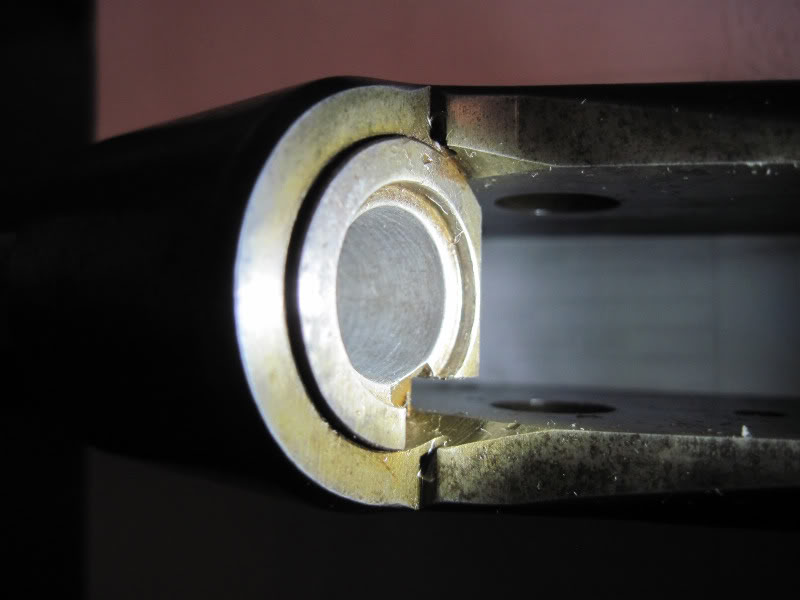

Refurbishing an Argentine RB - Part 9

Measuring the chamber

Joel, you have done a splendid job.

To instantly put your mind at rest, the rifle appears to have a perfectly normal .43 Spanish chambering, with acceptable military tolerance. I see no evidence that it has been reamed. You can order the 43 Spanish reloading material without worrying that it might be wasted.

Originally Posted by

killforfood

So Patrick, how did you know that this wouldn’t have a long throat when so many do?

All BPCRs have short throats to provide well-defined engagement of the bullet with the rifling. A long throat would let the bullet "jump the grooves" i.e. it would charge straight over a gradually tapered rifling, becoming partially stripped before finally engaging.

The comparatively long, gradual squeeze that can be used with jacketed bullets which already engrave with a thou or so of rifling will not work with soft lead.

We can now compare the meagre data I have on cartridge dimensions with your measured chamber dimensions: I have two sets of figures, one metric, one imperial. You will see that the agreement is not very close. I have no way of telling whether the figures are derived from drawings or measurements on original (unfired?) cartridge cases.

Originally Posted by

killforfood

Overall chamber length from breech face to the beginning of the rifling is 2.660”.

Looking at your pics, the neck section ends about 0.15" short of the left-hand caliper jaw. This would allow a case length of nearly 2.5" before the neck jammed.

I have 56.58 mm = 2.28" or 2.25" as figures for total case length.

You are OK

Originally Posted by

killforfood

Just ahead of the rim in the web area it was .526”

I have 13.31 mm = 0.524" or 0.516"

You are OK

Originally Posted by

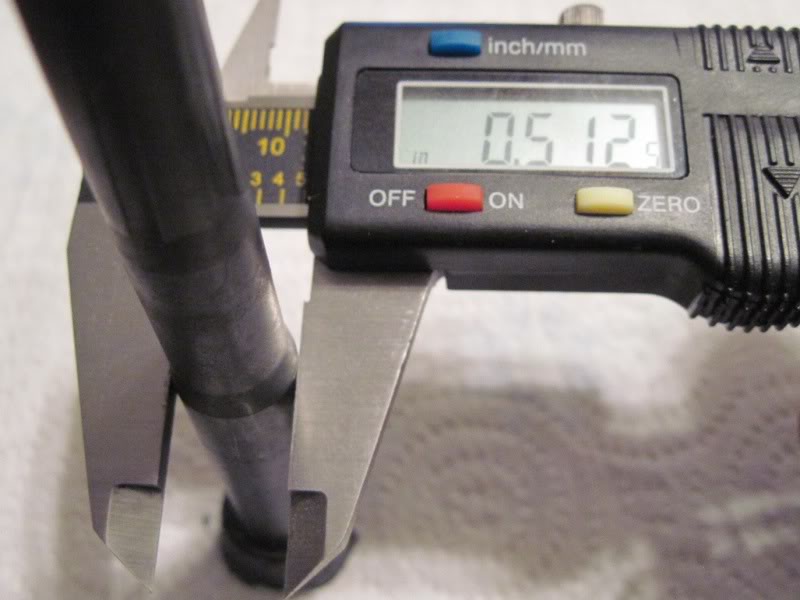

killforfood

The shoulder diameter is .512”

I have 12.77 mm = 0.503" or 0.512

You are OK

Originally Posted by

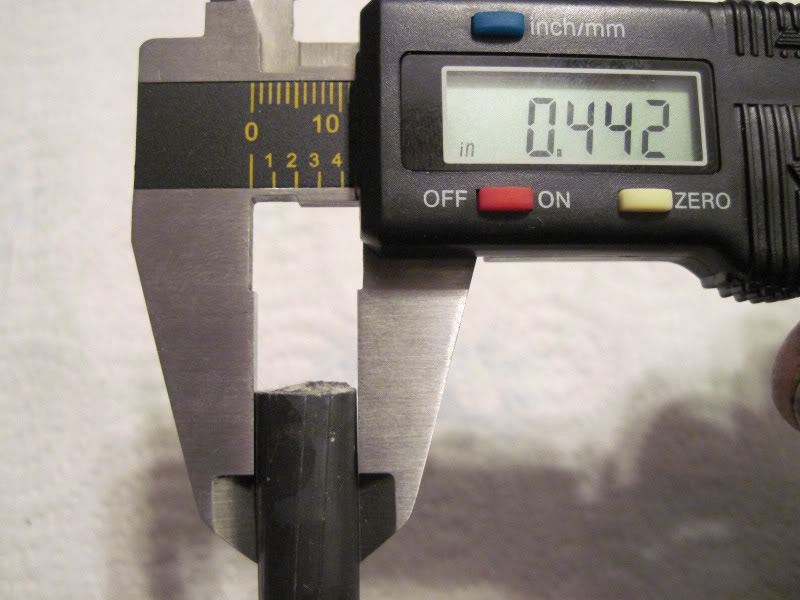

killforfood

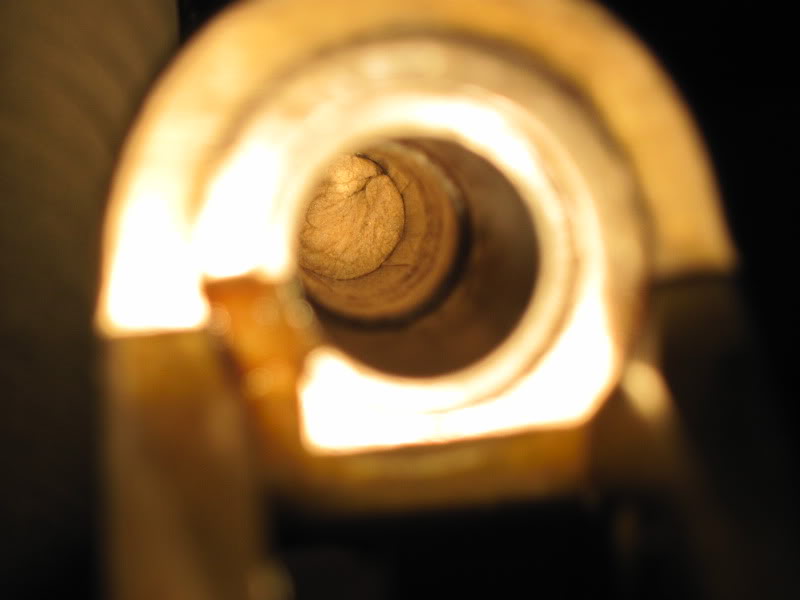

Groove diameter .442”

You will not be able to get a 452 slug down that bore with the brass rod method. 10 thou over groove size will NOT go. Even a "soft" lead pistol bullet will have a Brinell hardness of at least 15, more likely 20.

Originally Posted by

killforfood

This gave me a groove depth of .006”. Subtracting two groove depths gives me a bore diameter of .430”.

So you not only have a rifle in chambering 43 Spanish, the bore diameter is actually 0.43". It is not always so.

Originally Posted by

killforfood

The end of the neck is .460”

I have on record 11.54 mm = 0.454" or 0.455" for the cartridge.

You are OK

Originally Posted by

killforfood

The neck just in front of the shoulder is .464”

I have 11.55 mm = 0.455"

You are OK

Finally, rim thickness. You have not measured that yet. My figures are 2.26 mm = 0.089" or 0.065". That's quite a difference, but all that matters is that the bases of the cartridge cases that you buy will actually go into the recess and allow you to close the block. Looks like your rim recess is about 0.09-0.10" deep. For rim diameter I have 16.54 = or 0.635. That is not usually a problem.

At this point, I must advise you not to let yourself be scared by headspace doom-and-gloom soothsayers who have no idea about BPCRs and who will try to convince you that your rifle is going to blow up if the headspace is not correct to the micron. In such old rifles the secret of using those expensive cases over and over again is neck sizing, and nothing else. Fortunately, in the case of 43 Spanish there is probably no SAAMI data available for the armchair experts to get steamed up about (at least I hope so).

So once those cases have had a first firing, they will have expanded to fill the chamber as is, not as should be, and the cartridges will thereafter be headspacing on the shoulder. This means, of course, that those cartridges are only suitable for that rifle. For instance, I have an 1871 Mauser rifle and an 1871 Mauser Jaeger, and must keep the batches separate for each rifle. Not your problem yet, but give it time...

The only thing which you MUST check is that the block really does lock up tight. As the block rotates in the action, any slackness will mean that the cartridge base will become skewed if the block opens a bit on firing and can rotate backwards.

Conclusions:

- with the usual precautionary AFAICTWAHTOIMH !

You rifle is chambered for 43 Spanish. It has not been rechambered.

You will need lead-tin alloy bullets with about 5% tin - 95´% lead.

The lead must be reasonably pure - lead flashing as used by roofers is OK. Wheel-weights from the local garage are most definitely NOT suitable. The easiest way to get the tin content is to mix in lead-tin solder in the appropriate amount. At this point, please read up the thread on the 1871 Mauser, if you have not already done so.

You now need to order a bullet mould.

RCBS 82040, for a 0.439" 370 gn. bullet or Lyman 2640186 / 0.439" / 370 gn. will both work as cast.

When you have gained some experience with BP reloading, and are tuning for maximum accuracy, then you could try RCBS 82093 for a 0.446" 370 gn flat-nose bullet, or 2640110 / 0.446" / 340 gn. But in both cases you will need to size the bullets down to no more than 0.443". The full 0.446" may well go through the bore, but could cause a neck jam in the chamber. To evaluate that possibility you must first have the brass, so that you can measure the neck wall thickness.

We have now gone as far as we can with theory at the moment. In the end, that muzzle and crown (or rather, lack thereof) is going to be a decisive factor. So could you please make a couple of pictures of the muzzle end of the rifling, as suggested in my previous posting?

End of Part 9

Last edited by Patrick Chadwick; 12-05-2010 at 01:45 PM.

Reason: typos

-

-

Advisory Panel

Originally Posted by

killforfood

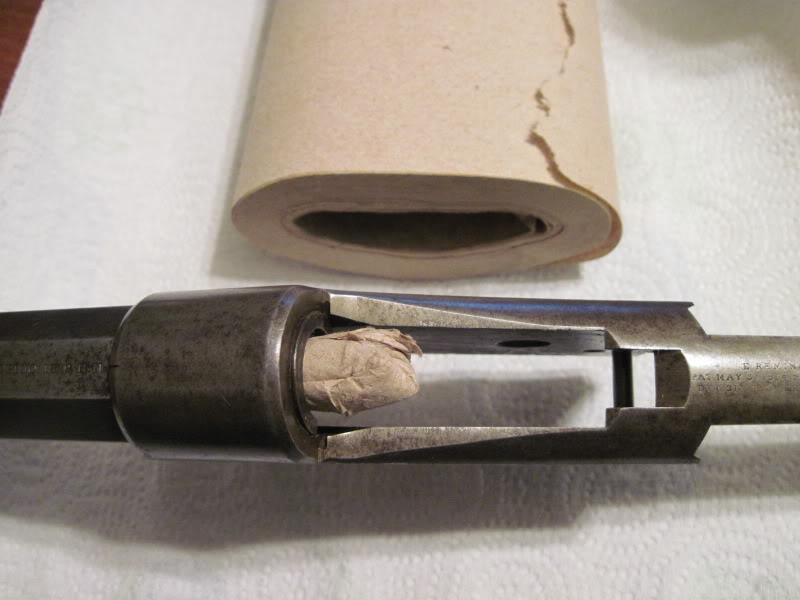

I assume Patrick that you will still want me to slug the bore to ascertain it's full length condition.

Yessir!

-

-

I think I'm going to have to respectfully disagree that Wheel Weight alloy is not suitable for BPCR. I shoot wheel weight all the time in Martinis and rolling blocks without issue. What makes the difference is the projectile design. If you have many narrow driving bands or paper patch, the alloy isn;t that important. If you shoot solids with long smooth sides, then yes, you need very soft lead. On my PP loads, I could probably use solid steel projectiles with no ill effect as the projectile is actually 1 thou under bore size. The grooves are engaged by the paper jacket only.

On my unpatched rounds, I use beeswax/crisco lubed bullets with several wide grease grooves. The bearing surface on the rifling is comparatively small, allowing harder wheel weight alloy to be used satisfactorily. The bottom line is that bullet design is as much a factor as alloy.

Here are my martini bullets:

On the left is a 440gr paper patched bullet, on the right a 490gr beeswax and crisco lubed bullet. I shoot these in Jamieson cases through a bone-stock Enfield made MkIII martini. with no issues whatsoever. Load is 85gr of GOEX FFg by volume.

At some point you will have to decide to either use real black powder (recommended by me) or substitute (not recommended by me, but others will try to steer you that way). IF you use black powder (I also don't recommend BP substitutes for a variety of reasons including pressure curves), you will need to learn about wax cookies, pan lubing, double-boilers, wad cutting and a number of other arcane 19th century rituals

Left to right: Kynoch commercial round, two of my PP loads, and a 1902 British Ordnance cartridge:

Ordnance cartridge:

And to prove I'm not just spinning a dit, here is a recovered lubed 490gr with obvious Henry rifling on it

Last edited by Claven2; 12-05-2010 at 05:41 PM.

Союз нерушимый республик свободных Сплотила навеки Великая Русь. Да здравствует созданный волей народов Единый, могучий Советский Союз!

-

The Following 2 Members Say Thank You to Claven2 For This Useful Post:

-

Advisory Panel

Yes But...

Claven2, I know your arguments are valid, but I don't want to put Joel off completely by drowning him in complexity. A couple of weeks ago he just wanted to know whether he should "give it a try or run for my life".

He has now been led down that delightful garden path which shows you that you can do a lot more than you think, but it also costs a bit more than you expected, and the fat end with old bangers comes with the care and feeding - when you discover that dies, cases and moulds etc cost more than the rifle.

I find your thin-band bullets a very good idea, and am already thinking how I could try it out, but was that an off-the-shelf mould? Or a custom job? And would you care to tell Joel what you paid for those Martini cases - it might put him off getting one!

So maybe I am keeping it deliberately a litte bit Yes/No without a lot of "maybe, if you do this and buy that and adapt the other". When I started with BP I heard so many conflicting opinions that it took me a long time to sieve out the gold from the dross. Joel is rocketing in weeks up a learning curve that took me years, showing some real pack-rat initiative in his work, and producing excellent results. Let's feed him the tricky stuff slowly, I think he's hooked now...

Er... Joel, if you're reading this...don't let differing opinions stop you turning that RB into a whizz-bang shooter! How's the "boning up" coming along?

As Kipling wrote:

"There are nine and sixty ways of constructing tribal lays,

And every single one of them is right!"

Last edited by Patrick Chadwick; 12-05-2010 at 06:40 PM.

-

-

Advisory Panel

BTW Joel, the pictures of the Martini cases from Claven2 illustrate my previous posting

Originally Posted by

Patrick Chadwick

So once those cases have had a first firing, they will have expanded to fill the chamber as is, not as should be, and the cartridges will thereafter be headspacing on the shoulder.

The cartridges at left and right are original, unfired. There is in fact a CIP specification sheet for the 577-450 chambering. But as you can see, the "real" shoulders on Claven2's cases are quite different to what came out of the factory. Full sizing will overwork those cases. But by using neck sizing (which I am sure Claven2 does) they will last a very long time - and knowing what they cost (I also have Jamison cases for my Martini), they have to last.

-

PM

PM

.

.