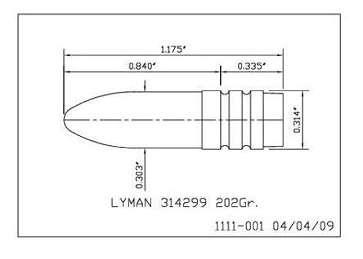

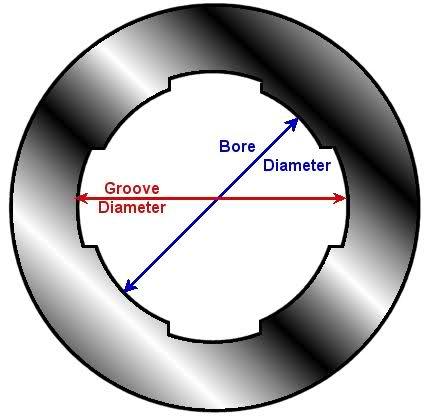

I have two Mk1* lee enfields in pretty good nick with good , early deep rifling in both barrels . I have shot commericial jacketed ammu . [150 and 175? gr ] with 06 and 08 and feel I can do better . Since these rifle barrels were originally shot with a 210 gr prog. I was wondering if anyone out there had already experimented along these lines and possiblely get a 210 gr mold ?! Lee only make a 185 gr and I found another at 195 gr . Im talking about cast bullets of course . Appriaciate all advice - thanksInformation

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current.

- Knowledge Library

- MKL Entry of the Month

- Australia

- Austro-Hungarian Empire

- Canada

- Czechoslovakia

- Denmark

- Finland

- France/Belgium

- Germany

- Italy

- Japan

- Norway

- Russia

- South America

- Sweden

- Switzerland

- Turkey

- United Kingdom

- United States

- Yugoslavia

- Is my rifle authentic or a fake?

- Jay Currah's Lee Enfield Web Site

- On-line Service Records (Canada)

- Technical Articles/Research

- Forum

- Classifieds

- What's New?

-

Photo Gallery

- Photo Gallery Options

- Photo Gallery Home

- Search Photo Gallery List

-

Photo Gallery Search

- Video Club

- iTrader

Register To Reply

Register To Reply