-

FREE MEMBER

NO Posting or PM's Allowed

Hi Alan, I'm not sure if this will post again but here goes.

I've been reading these posts on 308/7.62 and head space and am now not only baffled but worried...

I fully get the business about pressures and different measuring standards, not to mention thicker cases and the whole biz. No worries, I'm not reloading, no problem there, but I'm baffled as to head space.

What's concerning is that as you've pointed out the different gauges bear on the chamber in slightly different places and that in turn means that measurements taken at the cartridge base might be correct safety wise but will probably be different number wise for each gauge if measuring the length of the firing chamber to the cartridge base.

eg if I get my 7.62 ishapore, and use a no go for 308 winchester in it, is it possible that it might say all is OK, but when I use a 7.62 no go gauge it might say all is no go...and all that comes about as a result of the no go gauge being slightly further in or out depending on its design.

I know this because at the moment my rifle is too tight, so its very easy to see the differences.

When I strip the extractor off and firing pin out, and test the bolt and head with a 7.62 round in the chamber, then a 308 winchester round, and then one of those safety fire fake cartridges (?name) the bolt tightens up in three distinctly different spots, roughly about 15 degrees apart.

If I resurface the bolt face so that its correct with the .308, will it now be too loose for 7.62?

One measurement would reassure me if someone knows it; with a 7.62 round chambered, what is the acceptable maximum and minimum gap between the cartridge base and bolt head face?

Ok, now that would be great if I'm shooting nato rounds.

If I'm using 308 winchester, what is the acceptable max and min gap allowable between the cartridge base and the bolt head face?

Quote from Peter above;

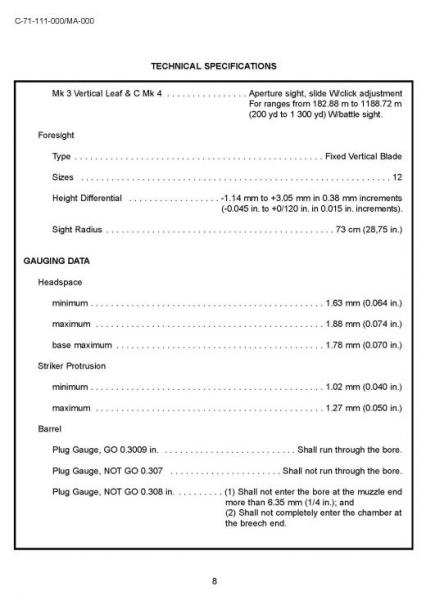

As for 7.62mm CHS gauges, in Britain , we had MANY variables. BUT, so far as this forum is concerned, we only had ONE set for bolt action rifles..., from the L8 series, right up to the L81 and that is 1.628 GO and 1.635 NO-GO.

, we had MANY variables. BUT, so far as this forum is concerned, we only had ONE set for bolt action rifles..., from the L8 series, right up to the L81 and that is 1.628 GO and 1.635 NO-GO.

Can I interpret that to mean a maximum gap of 7 thou, ie the difference, for 7.62 rifles?

sorry if we've covered this, but its giving me a headache trying to decide exactly how to make my too tight rifle safe to shoot. thanks to all...

-

08-01-2009 07:10 AM

# ADS

Friends and Sponsors

-

Legacy Member

You are not alone. I dont completely understand this issue either, (rimmed cases like the 303 are simple to understand) so being a bit of a "scaredy-cat" I decided to do what it says on the rifle.

If its proofed for 7.62 thats what I use, If it proofed for 308 thats what I use. (and headspace gauges to match)

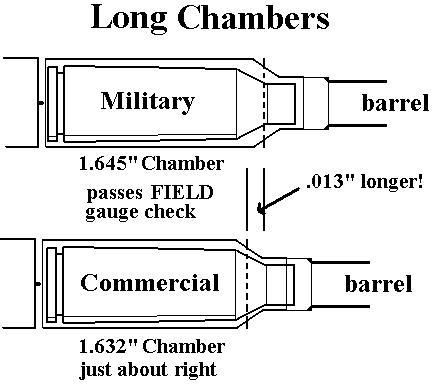

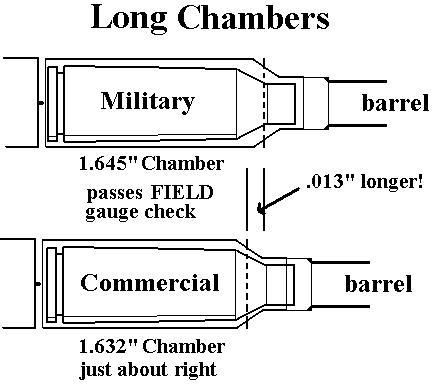

There is a difference of 13 thou in the chamber so swapping around will / can increase your headspace by 13 thou.

-

-

Banned

-

Legacy Member

The .303 British had a long history of evolution in the British military.

had a long history of evolution in the British military.

It began as a black powder cartridge chambered in a black powder rifle design. Both cartridge and rifle were changed to cross into the smokeless powder era.

Then comes war upon war in which the .303 cal Lee-Enfield was used.

Subsequently the .303 cartridge was changed more than once. It was also used in a variety of machine guns some that were not of British origin.

I have never seen original chamber and head space specifications for the .303 British cartridge or the Lee-Enfield rifle. By original I mean the original engineering drawings for both the black powder and smokeless powder cartridges and chambers. I suspect that over time there were changes in both the cartridge's and chamber's dimensions for the .303 cartridge as used by the British. This probably includes the headspace gauging standards. I have read of some comments that tolerances of British ammunition as well as trench warfare conditions lead to the demise of the Ross rifle and that Ross rifle chambers were then reamed over size in an effort to insure they would function. I have also read that the Ross rifles were considered to be very accurate. To some degree rifle accuracy is known to be related to a precision chamber.

John Sukey's comment brings up a point. What chamber will you get if you purchase on old original British sporting rifle in .303 especially non-Lee-Enfields such as double rifles, those made on Dutch M95 actions and the slant box Mausers?

The round was originally chambered in the US in the 1895 Winchester lever gun. It may have been chambered in other US sporting rifles such a the 1885 Highwall, Remington-Lee rifles and maybe others. In any event the standards in the US would have been established at that time. It seems to be SOP to claim that SAAMI standards are wrong as compared to current British standards. However it is my hypothesis that SAAMI standards are the original standards adopted by the US during original production of the cartridge and chamber combination. The US commerical arms producers had no reason to change their standards to parallel any British changes required by combat experience. Within a few years the .303 chambering was dropped in US commercial rifle production leaving only the production of ammunition in the US. While the SAAMI standards may not match up to Lee-Enfield specifications they may very well match up with the Model 95 Winchester specifications.

So there may be two sets of .303 standards for good reason. In the US we do not have large quantities of British military ammunition or brass. Until recently for decades we only had the brass and ammunition produced by 2 or 3 US commercial producers. Using this brass it takes special attention to detail to reasonable case life when reloading. This is important to anyone that shoots a good bit because 500 cases now cost the same as a decent rifle.

Most of the gauge makers are chamber reamer makers and they make untold variations of wildcat chamber reamers. I am sure that any of the gauge makers will make any head space gauge you require as a special. Just wave money at them.

All of this discussion seems unusual to me. In the collector world there are many that shoot their rifles little or none. I am not sure why they would even participate in such a thread. Those that are shooters but do not reload might have limited interest since they are going to discard their brass. Those that both shoot and reload would have signifcant interest since there is some motivation to insure they are getting the most enjoyment for their $$$.

Originally Posted by

John Sukey

It would be nice if Clymer provided headspace gages to BRITISH MILITARY SPECS instead of SAMMI specs.

What are the odds that you would find a .303 rifle set up to SAMMI specifications rather than British? How many current sporting rifles are made in .303???????

As far as I am concerned, SAMMI gages are a waste of time in .303 and the person who was thinking 30-40

Krag

rim thickness is the same as British .303

must have been smoking funny cigarettes!

-

Thank You to ireload2 For This Useful Post:

-

Advisory Panel

I suppose the bottom line here is, the SAAMI specs are not applicable to .303 British chambered milsurps for the simple reason they were never taken into account when the specs were done. By default, refer to the British H/S specs of .074" NO GO.

chambered milsurps for the simple reason they were never taken into account when the specs were done. By default, refer to the British H/S specs of .074" NO GO.

As you suggest, there should be very little concern about any of these sets of data due to the individuals own circumstances, except for re-loaders of commercial brass for milsurp rifles. The idea of having slightly tighter H/S for this situation to increase the lifespan of the brass is a $$$ consideration only and not in any way associated with safety concerns.

Of the several head separations I have seen and asked the shooters about, none could say they realised the case had failed untill they opened the bolt. I carry a ruptured case extractor to the mound, but have never needed it. I have seen one bloke have to use his during a rapid and still got ten shots away (with a compulsory reload) in 70 seconds. It's not the end of the world, just a little delay.

-

-

FREE MEMBER

NO Posting or PM's Allowed

Nicely described Ed. Dave_n

-

Banned

-

Banned

Originally Posted by

Son

I suppose the bottom line here is, the SAAMI specs are not applicable to .303

British

chambered milsurps for the simple reason they were never taken into account when the specs were done. By default, refer to the British H/S specs of .074" NO GO.

As you suggest, there should be very little concern about any of these sets of data due to the individuals own circumstances, except for re-loaders of commercial brass for milsurp rifles. The idea of having slightly tighter H/S for this situation to increase the lifespan of the brass is a $$$ consideration only and not in any way associated with safety concerns.

Of the several head separations I have seen and asked the shooters about, none could say they realised the case had failed untill they opened the bolt. I carry a ruptured case extractor to the mound, but have never needed it. I have seen one bloke have to use his during a rapid and still got ten shots away (with a compulsory reload) in 70 seconds. It's not the end of the world, just a little delay.

Son

The American SAAMI sets standards for civilian commercial ammunition and firearms only and it has NOTHING to do with American military standards or British and Commonwealth military standards. (Note: for some reason the M-14 and the Canadian FN C1A1 (FAL) have the same headspace settings and I think the British L1A1 has different headspace settings?)

FN C1A1 (FAL) have the same headspace settings and I think the British L1A1 has different headspace settings?)

My 1943 American Remington made Springfield 03-A3 30-06 ate Winchester cases in its long and fat military chamber like my .303 Enfield does, BUT Winchester cases in my 30-30 and .243 Winchester have NEVER given me any problems what so ever.

Our American SAAMI commercial cases were never designed to shoot in fatter and longer military chambers and this is one of the reasons why some match grade M-14s are rebarreled with SAAMI chambers and set to SAAMI headspace settings.

Below a complete set of American .308/7.62 headspace gauges in .001 increments.

Son, headspace standards are set by whose shoes or boots you are wearing and by what country the shoes and boots are located in.

I don’t wear military combat boots anymore and I have to take orders from the SAAMI on the care and feeding of my brass.

Look at this way Son, what do you think the headspace settings are for the Chinese copy of the American M-14 rifle are, the Chinese do not like the U.S. or the SAAMI. (read below)

http://www.fulton-armory.com/M14S_Eval.htm

-

Advisory Panel

Our boots may be on different sides of the planet, Mr Horton, but we sing from the same hym sheet.

For interest sake, the H/S gauges for an Aussie L1A1 are 1.6325 inch (accept), 1.638 inch ("soft body reject") and 1.640 inch (reject)

-

-

Advisory Panel

Head clearance is what matters

Dear All,

I have followed all these threads on the ever-exciting topic of headspace, and wonder why so much energy is devoted to the matter. As has recently been noted:

1) If you are a collector who does not shoot, the subject is academic.

2) If you shoot, but do not reload, the subject is academic as long as the headspace is not so extreme that cases separate on the first (and only) firing, which could really spoil your day out at a competition.

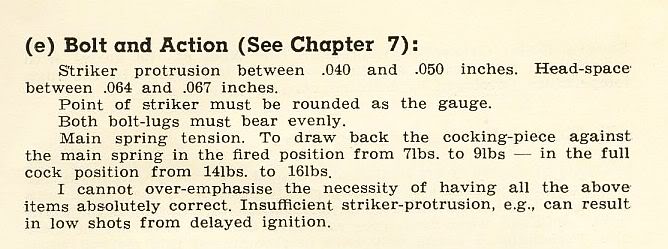

3) For target shooters who do reload, all the information presented up to now can be boiled down to the following, for practical purposes:

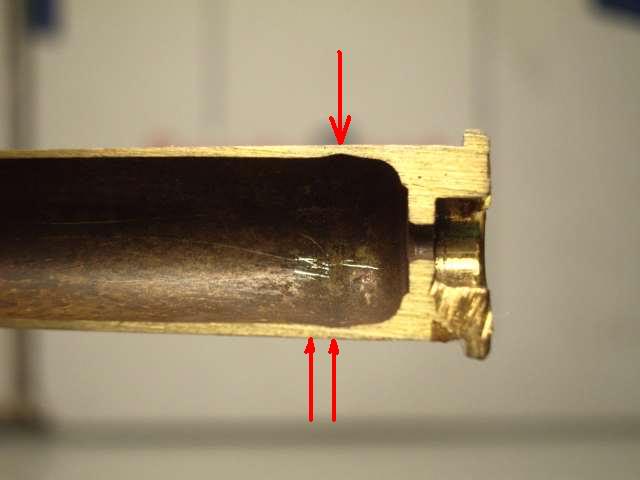

The headspace for a rimmed cartridge is the space between the bolt face and the face of the recess in the chamber that takes the rim. The stretch of the cartridge case is basically determined by the DIFFERENCE between the headspace and the thickness of the rim itself - something which I would call the head clearance between the rim and the (head)space into which it has to fit. In other words, the end play of the cartridge in the chamber. The matter is complicated by the dynamic effects of bolt/chamber compression and expansion, but the first step is to have that clearance as small as can be without it actually becoming negative (which would mean you couldn't close the bolt on the cartridge. So if the rim thickness varies from one manufacturer to another, then an obvious move is to use those cases which have the thicker rims.

The next step,followed by all Enfield shooters of my acquaintance her in Mauserland, is never to full-size rimmed cartridges, but only use neck sizing. Of course, the die must be set up (as also noted in recent postings ) to allow for the spring-back in the press, otherwise the result can be a case with the neck too far forwards that has to be cammed into the chamber, and can be very stiff to extract. Neck-sizing means, in effect, sizing the case as for a rimless cartridge, so that rim thickness and the head clearance are no longer the determining factors. This treatment reduces the end-play of the cartridge in the chamber to pretty much zero.

Dear Friends Across the Pond. You may not be aware that SAAMI was only set up in 1926, and many of our old service rifles were made long before. And although I pointed it out a year or so ago on the old board, only now are a few people in this forum reluctantly coming round to the idea that the British Empire utterly failed to make rifles to SAAMI standards. How very short-sighted! And failed to make a system suitable for endless reloading of cartridge cases. How wasteful!

Empire utterly failed to make rifles to SAAMI standards. How very short-sighted! And failed to make a system suitable for endless reloading of cartridge cases. How wasteful!

Turning off the sarcasm button and moving sideways a moment, consider the renowned M96 Carl Gustav (a.k.a. Swedish Mauser) rifles. Just about all made before SAAMI or even CIP. They swallow SAAMI no-go gauges without any problem. And cases fired in my Carl Gustav cannot be chambered at all in my Schultz & Larsen M69 match rifle (CIP standards). But head separation is not a subject for discussion - just use neck-sizing.

Mauser) rifles. Just about all made before SAAMI or even CIP. They swallow SAAMI no-go gauges without any problem. And cases fired in my Carl Gustav cannot be chambered at all in my Schultz & Larsen M69 match rifle (CIP standards). But head separation is not a subject for discussion - just use neck-sizing.

Or take a look at the bolt on the Swiss G96, 96/11 or K11, with lugs at the back. Then try and find "head separation" on the forums that cover Swiss rifles. No luck.

G96, 96/11 or K11, with lugs at the back. Then try and find "head separation" on the forums that cover Swiss rifles. No luck.

Synthesizing what has been put forward on this forum, a general recipe for milsurp and their brass is

1) First fire-forming with a slightly greasy case to get the maximum forming effect. I.e. merely wipe lube off case after sizing, but do not degrease it.

2) For all subsequent reloads, use neck-sizing with a properly adjusted press.

3) Except for that first fire-forming, keep all loaded cases dry to avoid continual and unecessary stress on the bolt lugs.

4) Forget SAAMI gauges, except for US-made rifles and ammo.

As usual, feel free to disagree, even heartily, but politely!

Patrick

-

, we had MANY variables. BUT, so far as this forum is concerned, we only had ONE set for bolt action rifles..., from the L8 series, right up to the L81 and that is 1.628 GO and 1.635 NO-GO.

Register To Reply

Register To Reply

in my American SAAMI Precision Mic gauge, it is .0015 (1 ½ thousandths) LONGER than my American Winchester .308 cartridge or 1.6295 and might be a tight fit in some chambers.

in my American SAAMI Precision Mic gauge, it is .0015 (1 ½ thousandths) LONGER than my American Winchester .308 cartridge or 1.6295 and might be a tight fit in some chambers.