In case anyone's interested, here's my latest attempt to mate a POSP scope to a VZ58.

Here is a "before" shot:

I went with a SVD-type mount for the basis of the project. This will be a permanent mod for a VZ58-type rifle to allow mounting of any POSP up to 6X. Larger objectives won't work as they would be too low the the handguard.

Anyhow, first step is to modify a standard POSP SVD mounting plate. This started out as the standard version sold by East Wave. About 1/8" had been milled off the top to fit the milled lightening cut height on the VZ sidewall and clear the lower pins.

Also, I positioned it laterally to get the right eye relief on either a 4X or 6X POSP using an NEA stock adaptor and AR stock, which is a bit longer length of pull than the standard stock. I didn't want to have to remove anything to strip the internals, so recesses are milled into the mount to allow the trigger group pins to be punched out.

Additionally, I had to mill a step precisely into the back of the mount to account for the stepped height of the receiver side wall.

This photo gives a good idea of what it will ultimately look like:

Next, you can see the back of the mount that better illustrates the pin relief holes and the stepped shape of the back of the mount to allow for the receiver step:

Note that none of the holes are co-located with the POSP bearing surfaces. the critical area is about mid-way along the bottom part of the dovetail where the POSP cam locks to the mount.

This next bit is not for the squeamish and is definitely the "point of no return".

Fresh from the welder:

Look at those nice full-penetration TIG welds:

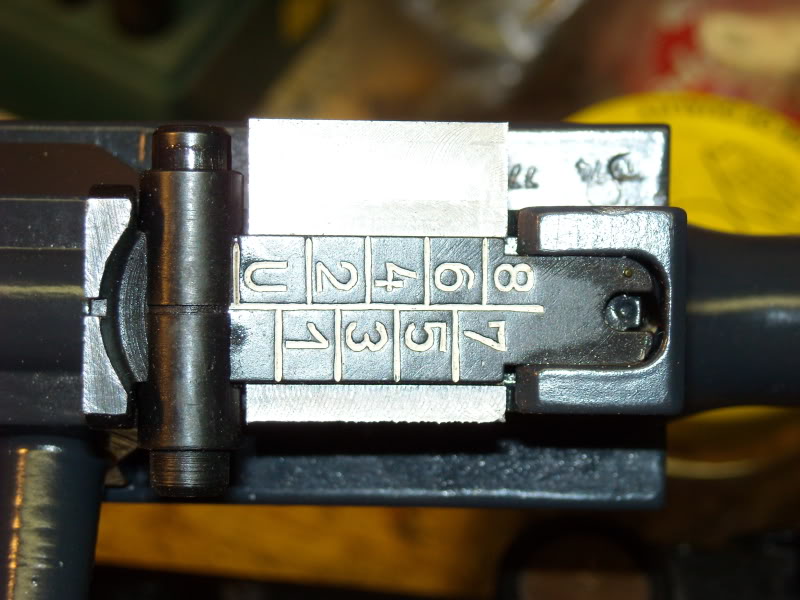

This is how I made sure the serial number is still visible on the rifle (yes, part is photoshopped out):

Tial fit:

This really shows the minimized offset:

Look at that tight 5 thou clearance between to mount arms and the receiver sidewall!

Bottom of mount flush with top of trigger guard, fo you lefties out there...

And after a little cleanup with file and paper:

With the scope offset minimized, I had to fab up a shell deflector.

Started with a chunk of 1018 cold rolled steel and the mill:

Here it is clipped under the rear sight leaf:

Next, I cut a piece of 1018 hot-rolled bar stock and milled some lightening cuts into it and MIG welded it to the rear sight wedge:

Finally, I fabbed up a piece of 1020 colled rolled sheet steel into a deflection shield, drilled some plug weld holes into the tab and then plug welded it to the support arm, then dressed the welds down with an angle grinder and finished dressing it with a file:

And here it is mocked up:

I still have to finish it, probably parkerize it or nitro-carburize it. Not sure yet. It fits nice and tight as it's milled with only a couple thou clearance to the slide and the machining on the bottom fits the spring recess for the rear sight perfectly. The spring tension keeps the deflector in place and it has just enough give to it that it should absorb all the shock of being hit by shells without ever getting near the scope Information

Information

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current.

- Knowledge Library

- MKL Entry of the Month

- Australia

- Austro-Hungarian Empire

- Canada

- Czechoslovakia

- Denmark

- Finland

- France/Belgium

- Germany

- Italy

- Japan

- Norway

- Russia

- South America

- Sweden

- Switzerland

- Turkey

- United Kingdom

- United States

- Yugoslavia

- Is my rifle authentic or a fake?

- Jay Currah's Lee Enfield Web Site

- On-line Service Records (Canada)

- Technical Articles/Research

- Forum

- Classifieds

- What's New?

-

Photo Gallery

- Photo Gallery Options

- Photo Gallery Home

- Search Photo Gallery List

-

Photo Gallery Search

- Video Club

- iTrader

PM

PM