-

You do that, I'm already well into this silliness.

Everything else I do to waste time costs more!

-

-

05-01-2010 08:23 PM

# ADS

Friends and Sponsors

-

Banned

Originally Posted by

Surpmil

JM, you're wasting your time. PO Ackley already did the destruction tests a long time ago.

They tell nothing relevant to this "debate".

Why don't you get a nice 1950s No4 Mk2 and strip off the wood, set it up in a fixed rest with remote trigger release, arrange a garden hose to spray a mist of water over the bolt and magazine and fire off as much .303 as you care to waste?

You can check the HS with HS gauges and feeler gauges at the start and after every 10 or 100 rounds.

Having done that, you can proceed to do the same in 7.62mm.

My guess is you'll waste a lot of ammo and determine nothing, but if you want a relevant project, that would be it IMO.

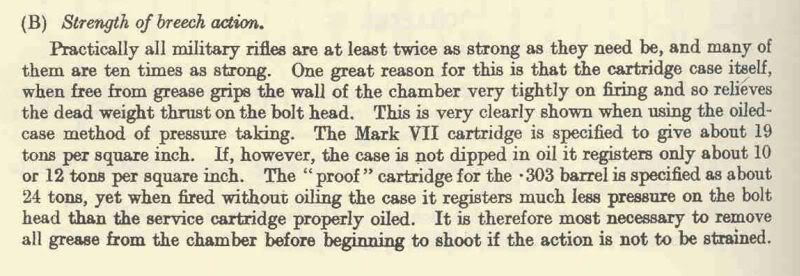

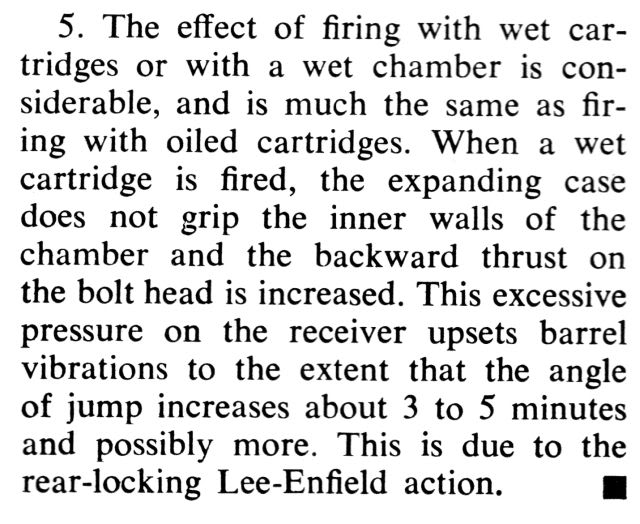

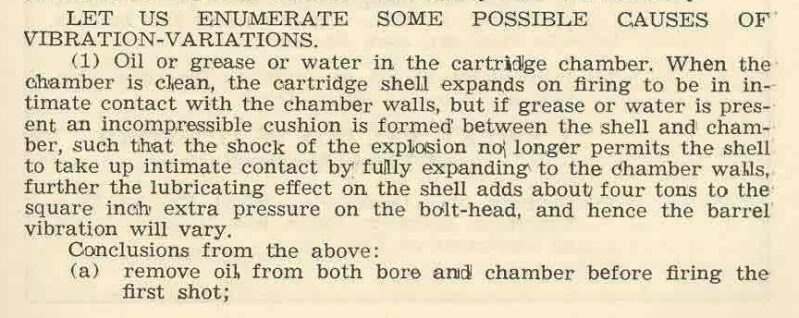

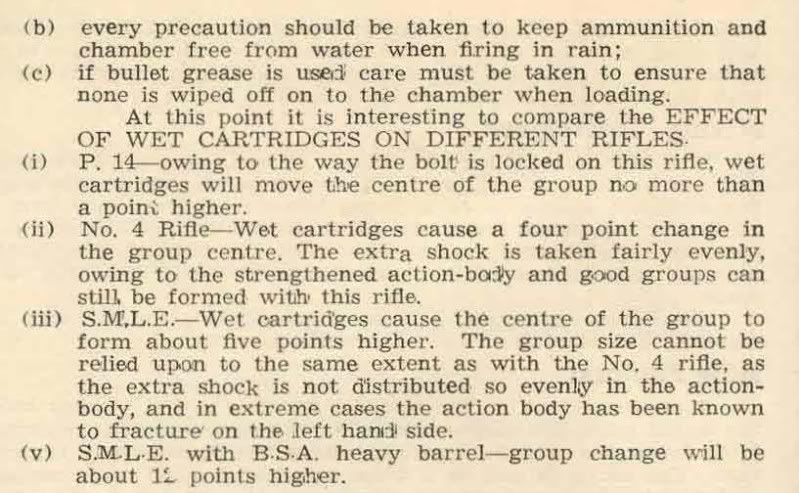

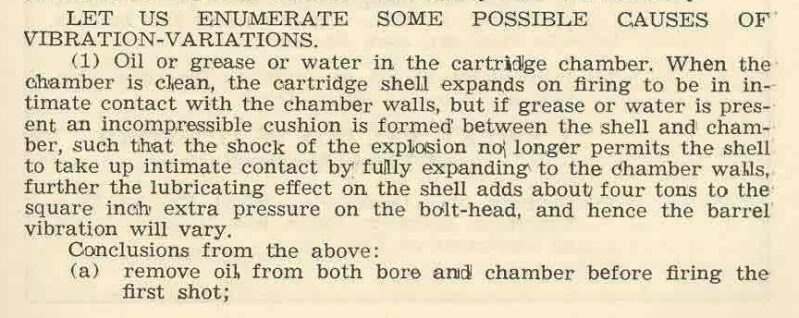

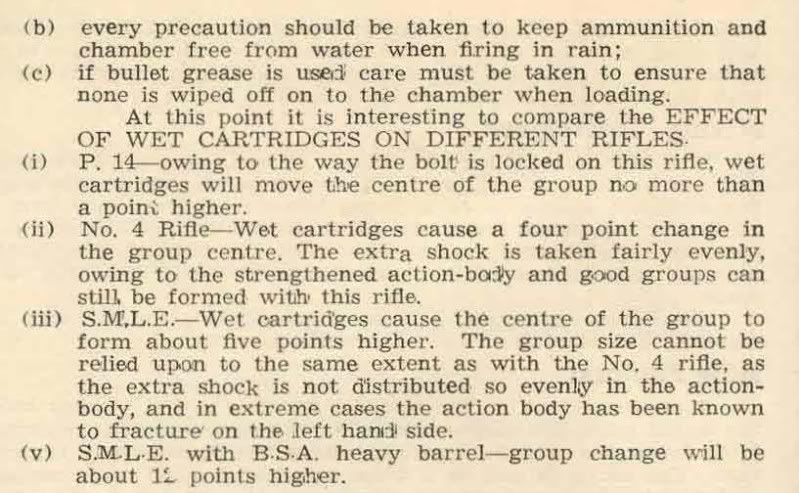

Two scans from the Textbook of Small Arms 1929. I think they speak for themselves, but the obvious conclusion is that could the base of the cartridge be made strong enough, and the blowing out of gasses through the primer holes be prevented, rifles could be fired without any kind of breech block or bolt at all, assuming there is no grease or oil present in the chamber. I notice that there is no reference in the Textbook of Small Arms 19129, at least not that I have seen, to any such issues surrounding the presence of water in the chamber.

If anyone else has noticed such references in their reading I would like to hear the details.

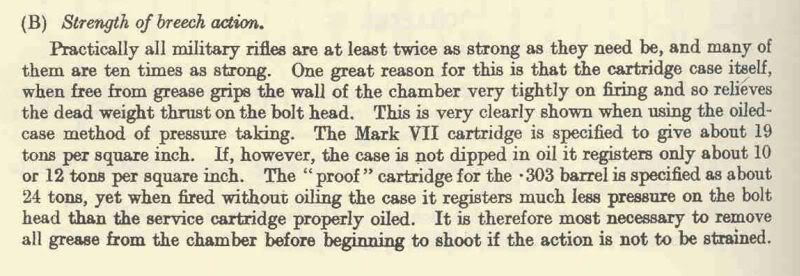

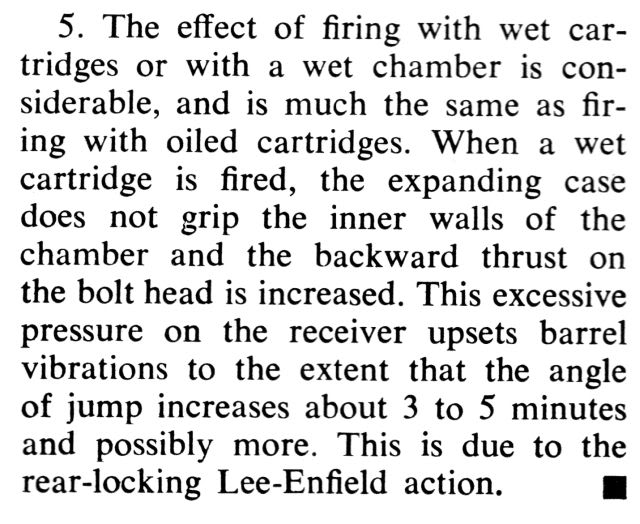

The British Military and the War Office have long ago figured out how much more bolt thrust you will have with grease, oil or water in the chamber. Please read below, this equates to a 52.6% to 63.1% increase in bolt thrust with oil or water in the chamber of the Enfield Rifle

Military and the War Office have long ago figured out how much more bolt thrust you will have with grease, oil or water in the chamber. Please read below, this equates to a 52.6% to 63.1% increase in bolt thrust with oil or water in the chamber of the Enfield Rifle . It also states to remove all grease from the chamber if the action is not to be strained.

. It also states to remove all grease from the chamber if the action is not to be strained.

From "The Textbook of Small Arms" dated 1929

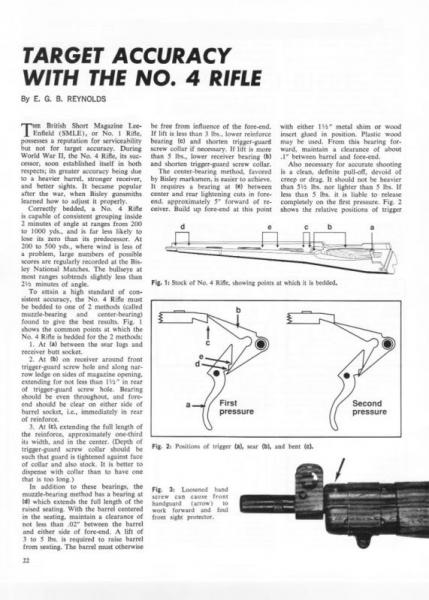

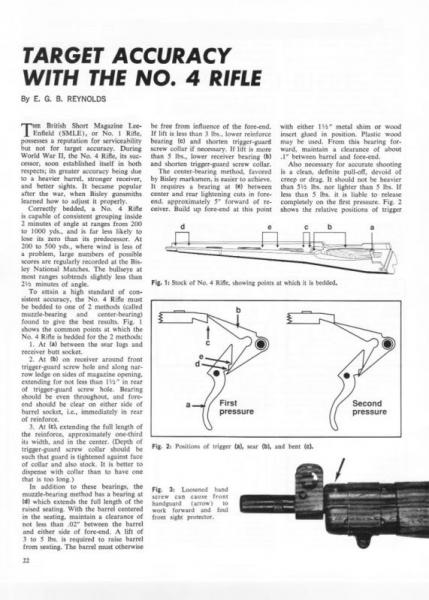

From E.G.B. Reynolds

Jim Sweets "Competitive Rifle Shooting". Dated 1946

With the .300 Winchester Magnum you aren't just reinventing the wheel, you are putting a rocket motor on Ben Hur's wooden chariot.

You are planning to use a cartridge case with more surface area and a larger base diameter than the .303 British or 7.62 NATO.(A large unknown without proper test equipment) The larger base diameter of the .300WM creates MORE bolt thrust due to its larger diameter. Therefore you are not even comparing apples to oranges and now you want to throw a watermelon into the mix and compare that to smaller fruit.

The issue is how much damage will continued firing of the Enfield rifle with water, oil or grease in the chamber will actually do. Or how fast and how much will the head space increase with the additional bolt thrust using a .303 or 7.62 cartridge when the cartridge case is not gripping the chamber walls. (With over a 50% increase in bolt thrust)

Old Engineering term "KISS" or Keep it simple stupid

Added thought Mr. jmoore, fire up your synaptic network and stimulate your gray matter.

Guess which end of the bolt is effected the most by bolt thrust and which end does head space increases the fastest. Go ahead and think about it and then think about it some more. (You replace both bolts and bolt heads to decrease head space)

Last edited by Edward Horton; 05-01-2010 at 11:13 PM.

-

Advisory Panel

Hm, No1 bodies fracturing due to wet cartridge cases and chambers?

I'm a bit sceptical based on a little thing called the Western Front, 1914-1918.

And then of course there's S.E. Asia Command 1941-45.

Peter, any stories of fractured No1 bodies due to wet ammo or chambers from the older armourers of your acquaintance?

-

-

Banned

-

I've several SMLE bolt heads that are broken off at the end of the threads (found 'em in bolt bodies).

Mr. Horton, I believe I've already postulated earlier in this thread and in another that I expect the front of the bolt to be the area of highest loading and subject to failure first.

I really don't care about the wet/dry chamber controversy so much as the British NRA's contention that the No.4 action is unsuitable for whatever 308/7.62x51 loads you care to feed it. I'm not looking to induce catastrophic failure so much as to see in an accelerated sense what WILL go "wrong" and if there are tell tale warning signs that the "average Joe" can detect. Since 7.62x51 has been used in this action for a "while" (1960's to start- 1970s in largish quantities and w/ high round counts), it seems that a futher step up is needed to see, in a reasonable amount of time, what the progressive failure mode might be.

NRA's contention that the No.4 action is unsuitable for whatever 308/7.62x51 loads you care to feed it. I'm not looking to induce catastrophic failure so much as to see in an accelerated sense what WILL go "wrong" and if there are tell tale warning signs that the "average Joe" can detect. Since 7.62x51 has been used in this action for a "while" (1960's to start- 1970s in largish quantities and w/ high round counts), it seems that a futher step up is needed to see, in a reasonable amount of time, what the progressive failure mode might be.

I, quite frankly, don't expect a whole lot to happen in this test under normal operating conditions. If I get bored trying to wear it out, then that's a GOOD thing!

-

-

Advisory Panel

Say, if you want some fun JM, why don't you try this: thoroughly oil the bolt and chamber of a Ross MkIII and fire a couple of hundred rounds off and see if the HS changes.

In The Ross Rifle Story there is an interview with a Sgt. Bill Carey, MM* (that means he won the Military Medal twice), who "...one fateful afternoon at Courcellette...fired some 200 rounds in rapid succession, single handedly wresting frontal control from the enemy's line to his own. His explanation for a perfectly performing Ross rifle that day was simple: "Before I started shooting, I emptied my oil bottle into the breech."

Now I wonder if Sgt. Carey knew something about case adhesion and was taking care to make sure that if the ammo was soft or oversize, it wouldn't stick in the chamber. He did say in the interview that in his use of the Ross in WWI, it "never once jammed," but neither did he usually oil his bolt and chamber. Probably as a sniper he chose his ammo carefully.

Last edited by Surpmil; 05-05-2010 at 09:12 PM.

-

PM

PM