-

Advisory Panel

Originally Posted by

Lucite

okay so under 0.031 is all I need to know

Yikes! Please don't think that's all you need to know!

I'd guess from your response you're thinking I've given you a specific dimension that will work for your rifle. Actually, I'm trying to explain the underlying principles involved so you can determine for yourself how much would be too much.

Use a marker on the closed bolt to show you how far the bolt head extends into your receiver ring - it might be more or less than what we see on the picture of my bolt. Then proceed with fine file or abrasive stone to make a very small chamfer in the area where the bolt head is jamming on the receiver ring, taking off no more than .003". Try it in the rifle with an inert cartridge ("dummy round"). If it works, stop there! If not, take off a little more metal and try again. Repeat as necessary. If your chamfer is getting close to the marked area, stop there!

This business of "cut and try" is a traditional method used in hand-fitting firearms. It can be tedious because each cut is very small - but it works when the brain controlling the tool has sufficient patience. If that doesn't describe your approach, please hand the job to someone better suited for it.

-

-

12-28-2011 12:39 PM

# ADS

Friends and Sponsors

-

Legacy Member

I used a needle file when I did mine, It looked a bit rough but when it worked, the roughness soon nicely rounded after I racked a few dozen drill rounds through it.

-

-

-

Legacy Member

Originally Posted by

Parashooter

Yikes! Please don't think that's all you need to know!

Sorry for the misunderstanding I didn't mean that 0.031 was how much to take off rather the space I had to do it in, I only took of about .002 if that from the contacting edge and still no change. I'm debating weather to take it to a gunsmith now or to just sell it and remove the headache it has been causing.

Last edited by Lucite; 01-02-2012 at 09:12 AM.

-

-

Advisory Panel

" . . . proceed with fine file or abrasive stone to make a very small chamfer in the area where the bolt head is jamming on the receiver ring, taking off no more than .003". Try it in the rifle with an inert cartridge ("dummy round"). If it works, stop there!If not, take off a little more metal and try again. Repeat as necessary."

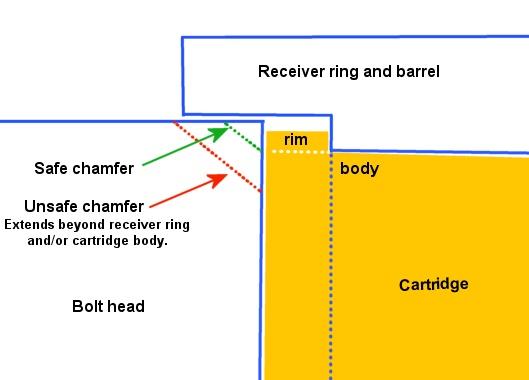

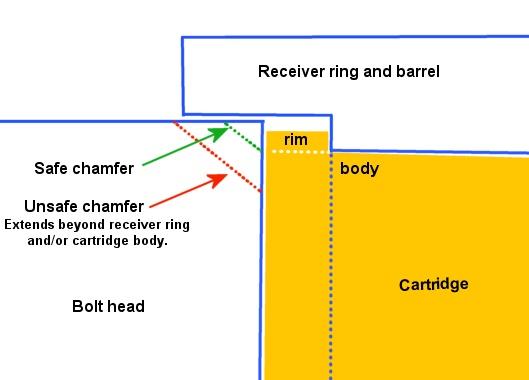

Sometimes when words aren't working, we draw pictures -

The problem with taking it to a commercial gunsmith is that many of them don't know much about either the basic principles involved or the specifics of the Lee-Enfield. If you can find someone knowledgeable on both, he can probably fix it in under five minutes with a few judicious file strokes.

Last edited by Parashooter; 01-02-2012 at 05:36 PM.

-

The Following 2 Members Say Thank You to Parashooter For This Useful Post:

-

Legacy Member

I managed to take it to a gunsmith and he said it was due to an improperly fit magazine causing the bolt head to lift up.

-

PM

PM