-

Legacy Member

My Great Big MkII** Ross Rifle Project.

Hi Everyone

Recently picked up a MkII** (assuming it to be a commercial) .303 that has at some time in its past been seriously "got at", and as a result there's an amount of work and (unobtainable) componentry required to get it back to something nearing its original (glorious) condition.

What I intend this thread to be is a place to chart the progress I'm making towards the restoration, but also somewhere I can ask a few of the questions I'm bound to encounter along the way.

Among the unobtainable trinkets that my rifle is currently missing, :

#MkII** Nose Cap (to suit the heavier profile barrel)

#Rear sling swivel

#Bolt that retains the middle barrel band

#MkII front sight assembly--------------(FOUND)

#Now just need the sight hood

#"Keeper Ferrule"-------------(DONE)

Now given there's not been a ross made in close to 100 years, and that these same items are the ones everyone seems to be looking for: I'm very realistic about the prospects of tracking some of these parts down - so I'll be looking to machine/fabricate any of those which I can't source in the meantime.

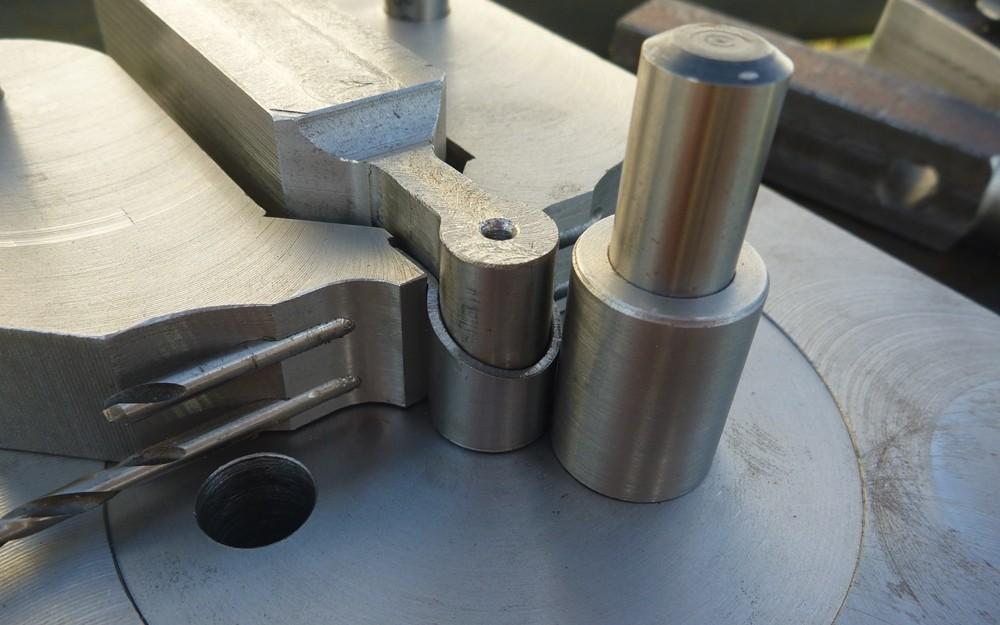

The first of those parts I've resorted to making is the serrated "keeper Ferrule" (not sure of the official Ross Nomenclature) that engages the twin front action screws of the MkII ross (assumedly to prevent the screws loosening under recoil) . Had been told these tiny little pieces are virtually unobtainium, and can certainly imagine these'd be the first item lost once a rifle's been disassembled a number of times and in reality its probably of questionable necessity to the rifles machinations anyway.

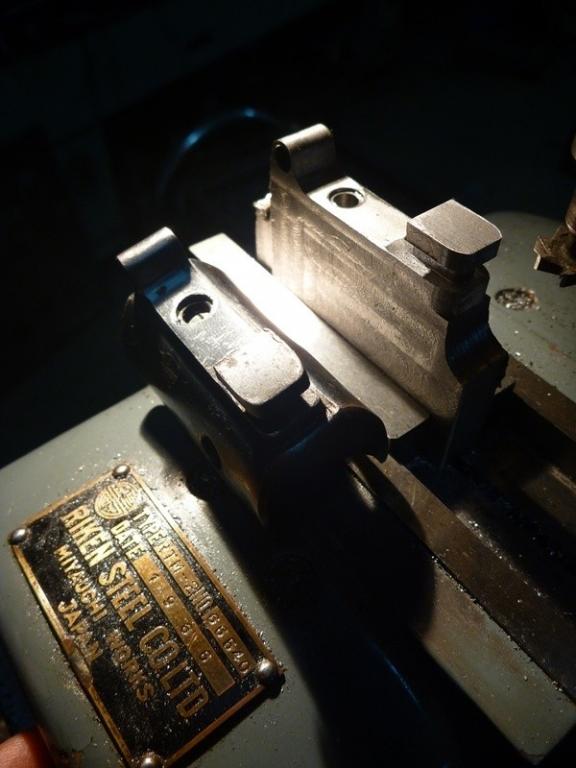

Mill set up in horizontal guise with the dividing head

Close up of the machining details

Note: The split magazine box and twin front action screws (and serrated keeper) necessitated by the arm of the "Harris" follower being on the centre line of the action.

The "Keeper" installed in its pocket, engaging the other screw heads.

The heads of these action screws are visibly mangled so if these can't be tidied up a bit, I may resort machining some replacements of these too. ("slippery slope"... I Know)

Does anyone know the dimensions of the little bolt that holds the "keeper"?

Also wondering if anyone's got drawings or dimensions for a II** (heavy) barrel? If not can anyone can comment on how close the barrel profile might be, to those used on the later MkIII's? The situation is the barrel on mine has been shortened from its original 30 1/2" length, and I'm thinking its a "ring-in" that's been fitted at a much later date (so can't really base my profile measurements off this, to order the new barrel).

"TSE" a local Australian barrel maker has a profile on record for a "Ross Rifle" (generic) from diameter measurements he has lifted off a MkIII DP rifle and I need to determine how close this would be to what II** is meant to have?

barrel maker has a profile on record for a "Ross Rifle" (generic) from diameter measurements he has lifted off a MkIII DP rifle and I need to determine how close this would be to what II** is meant to have?

Any info would be really appreciated

Thanks

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

Last edited by BrianLara400*; 10-15-2014 at 07:01 AM.

-

The Following 4 Members Say Thank You to BrianLara400* For This Useful Post:

-

10-15-2014 05:40 AM

# ADS

Friends and Sponsors

-

FREE MEMBER

NO Posting or PM's Allowed

Whilst unable to contribute to your project in any way, nevertheless I look forward to reading about your progress.

-

Legacy Member

-

Thank You to BrianLara400* For This Useful Post:

-

Legacy Member

-

-

Advisory Panel

I'd be up for a couple of the little keeper bushings and 3 MkII** nose caps....

Awesome work by the way...

-

-

Legacy Member

Great to see the old engineering / Tool making skills still in use

-

-

Contributing Member

Pretty tidy work all round not to much swarf or chips great to see as to watch a CNC or an automated lathe at work is like watching bats in a dark cave if you get my drift...................

-

-

Legacy Member

-

The Following 2 Members Say Thank You to BrianLara400* For This Useful Post:

-

Advisory Panel

So, I thought I was doing well making my own wrenches for an M1 rifle receiver and barrel. I daily converse with men that make their own forming and machining jigs...at least it leaves me in good company...nice work on the scarce and unobtainium parts.

rifle receiver and barrel. I daily converse with men that make their own forming and machining jigs...at least it leaves me in good company...nice work on the scarce and unobtainium parts.

-

-

Legacy Member

Very nice machine work. We appreciate the photography and updates. Salt Flat

-

barrel maker has a profile on record for a "Ross Rifle" (generic) from diameter measurements he has lifted off a MkIII DP rifle and I need to determine how close this would be to what II** is meant to have?

PM

PM