-

Legacy Member

Originally Posted by

Pedantic_Potato

Good question. I was a little less than smart when I installed it and the front blade is canted at least a couple degrees off center to the left... It's a repro front sight and the barrel is a gunsmith re-barrel (the bore of the original was worn out and mildly corroded) that lacked a front sight.

The front sight shouldn't have any adjustment rotationally with the right parts. The barrel keyway, sight key, and front sight should all fit together tightly. If the front sight is tight but canted, your new barrel might not be indexed properly. Check the tick marks on the barrel shoulder and receiver, then check alignment using two bubble levels from the receiver and barrel flats.

Originally Posted by

Pedantic_Potato

Add to all of this a bad roll of the celestial dice regarding 1984 Korean surplus .30 Carbine from SGAmmo (about a quarter of the 1080 rounds have the green/blue corrosion on the brass cases/up the sides of the bullets themselves), and it's safe to say that I've had quite a few less than stellar experiences with my

M1

Carbine. That's not to say I don't like the rifle, but I just can't seem to catch a break haha. Sorry for the ranting/rabbit trailing. Here's to hoping my streak ends!

The Korean ammo is great shooting ammo but there are some "bad" cans in the mix where moisture got in. I also received several with similar issues, one 84 and one 85. Several others were absolutely perfect like it was made yesterday. The discolored rounds look a bit ugly but I deemed all mine safe to shoot and have shot them up already. There's a few posts on CC forum where the ammo has been discussed. Watch out for pierced or slightly backed out primers on the 84, I've had a very few where that happened.

-

Thank You to GotSnlB28 For This Useful Post:

-

01-02-2021 12:00 PM

# ADS

Friends and Sponsors

-

Legacy Member

Originally Posted by

GotSnlB28

The front sight shouldn't have any adjustment rotationally with the right parts. The barrel keyway, sight key, and front sight should all fit together tightly.

It could also be poor installation of the front sight on my part since I remember stripping some metal off of the front sight key that sits in the barrel recess/dovetail. That's probably a function of me not owning a vice this time last year when I installed it, but I will check my barrel alignment since I don't think that issue beyond this carbine or my luck.

Originally Posted by

GotSnlB28

The Korean ammo is great shooting ammo but there are some "bad" cans in the mix where moisture got in.

Yup. There is a corner of the can that is quite rusty and the stripper clips near that point were definitely exposed to moisture (not to mention the ammo itself). I'll take a look at the CC forum and read more up on it. Maybe I'll take some photos of the various conditions of the rounds and post them here for advice as I am a new shooter dealing with surplus ammo.

Zeke H.

"Gentlemen, this is a story that you will tell your grandchildren, and mightily bored they'll be!" - Sir Brian Horrocks, 1944.

-

-

-

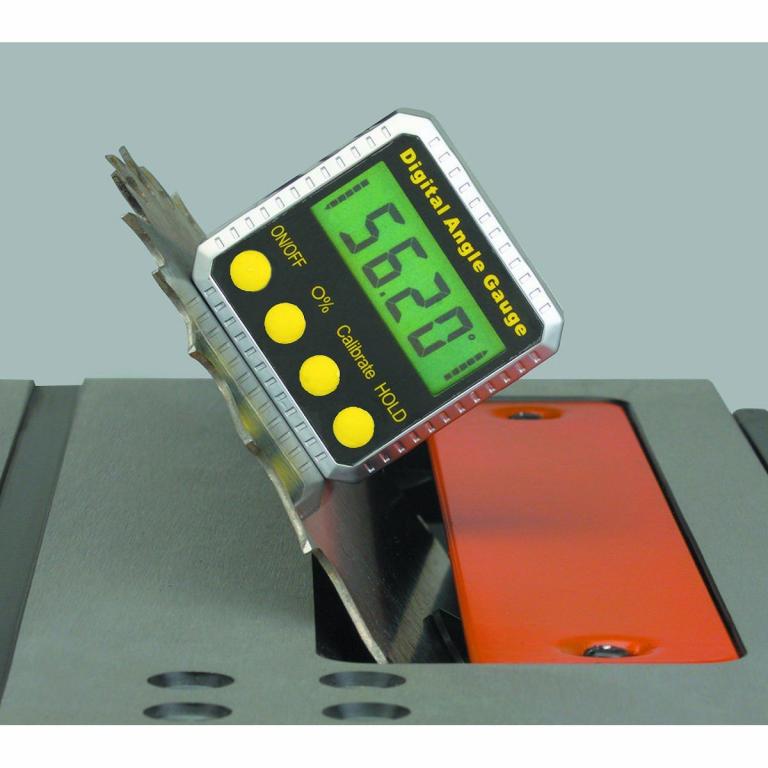

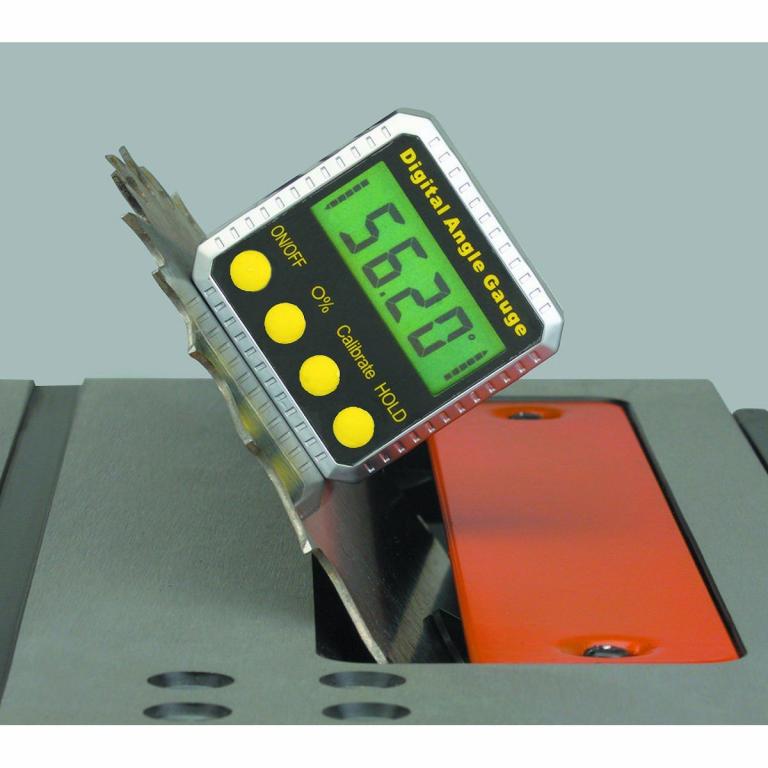

Magnetic Angle finder

Magnetic Angle finder guages. I purchased a set for multiple uses, like checking the angle on the table saw blade and the other on a Mitre saw. The 2 I bought are digital display and cost more but they all do the same thing. Being magnetic their nice to use on the carbine barrel flat and the flat on the receiver bottom. As long as they both read the same, you know your on the money. IMO much easier than using 2 straight edges or levels. Like most tools and gages you'll find more uses for them after you have em.

Mine look like this, but cheaper than the link and a different maker.

I've seen these on Ebay for 1/2 the cost and Home Depot carries versions.

https://www.harborfreight.com/digita...uge-63615.html

Here: Cheaper, Not Digital, but do the same thing, just read the scale. Both scales match- your parallel:

https://www.harborfreight.com/dial-g...der-34214.html

Really quick easy way to see if the barrel and receiver are parallel.

Charlie-Painter777

A Country Has No Greater Responsibility Than To Care For Those Who Served...

-

The Following 3 Members Say Thank You to painter777 For This Useful Post:

-

Legacy Member

Originally Posted by

painter777

Magnetic Angle finder guages. I purchased a set for multiple uses, like checking the angle on the table saw blade and the other on a Mitre saw. The 2 I bought are digital display and cost more but they all do the same thing. Being magnetic their nice to use on the carbine barrel flat and the flat on the receiver bottom. As long as they both read the same, you know your on the money. IMO much easier than using 2 straight edges or levels. Like most tools and gages you'll find more uses for them after you have em.

I'll pick a digital up if there's one at my local Ace Hardware or Home Depot. I can see the utility of the tool for all manner of things, not just checking barrel-receiver alignment. Thanks for the heads up, GotSnlB28 & painter777!

Zeke H.

"Gentlemen, this is a story that you will tell your grandchildren, and mightily bored they'll be!" - Sir Brian Horrocks, 1944.

-

-

Legacy Member

Originally Posted by

Pedantic_Potato

Interesting, that seems like a effective way to do it. Any advice on the size of the set screw or any specialized tools I may need to be in a position give that a shot? I would do this on a commercial reproduction sight since mine is original Inland from what I can tell.

5/32 or 3/16. You have plenty of exposed base after you traverse the ramp to either extreme. You need a drill bit of the correct size to match the desired size tap. You could use a larger screw, just chose one that bottoms-out below the top of the base when installed. This fix will allow you to adjust or remove the sight down-the-road if necessary.

-

Thank You to floydthecat For This Useful Post:

-

Legacy Member

Originally Posted by

flydthecat

5/32 or 3/16. You have plenty of exposed base after you traverse the ramp to either extreme. You need a drill bit of the correct size to match the desired size tap. You could use a larger screw, just chose one that bottoms-out below the top of the base when installed. This fix will allow you to adjust or remove the sight down-the-road if necessary.

Thank you for those recommendations! I'm very glad I got a few different fixes to my rear sight problem (and one that I hadn't seen previously at that!).

Zeke H.

"Gentlemen, this is a story that you will tell your grandchildren, and mightily bored they'll be!" - Sir Brian Horrocks, 1944.

-

-

Legacy Member

I don't like to do anything that a period armorer wouldn't do, in an effort to keep the carbine correct. Maybe that's not an issue with this one, but for this problem I would take the sight out, support the edge of the dovetail on an anvil or other hard surface, and lightly peen the other dovetail of the sight - very lightly! now try to re-install it and you'll find its going to be tight, but it sounds like you have the sight-pusher to use. Careful that its not too tight - if the receiver may have a hidden crack there it won't stay hidden. You may have to file the points a little where you peened up metal - its a judgement thing - the sight has to be tight but it also has to move when you crank down on the pusher. Due to how this sight is made, it will be difficult to peen it the way I said without having three hands. Maybe you can put it in a vise - upright, like it sits on the carbine, and judiciously squeeze the points to peen them. I think either way will work and never raise any eyebrows over it.

'Really Senior Member'

Especially since I started on the original Culver forum. That had to be about 1998.

-

-

Legacy Member

If you have a nice carbine, you should not do anything to it that is not in the original manuals - no Loctite, no shims. You don't want to peen on the receiver, so the only thing you can reasonably do is peen the sight dovetails as already described, by standing the sight on an anvil on one of its dovetails and peening on the other one. Just a little should do it - you will be surprised how little it takes. Then you really will need that sight pusher. BTW, why did you use a sight pusher in the first place if the sight will fall out? Couldn't you just push it in, or maybe tap it in?

'Really Senior Member'

Especially since I started on the original Culver forum. That had to be about 1998.

-

PM

PM

Especially since I started on the original Culver forum. That had to be about 1998.

Especially since I started on the original Culver forum. That had to be about 1998.