-

Banned

Originally Posted by

Dimitri

That is the point me and Ed are trying to make nothing more.

I went to college for Tool and Die, and learned both in school and at work about the properties of metal, heat treatment and the selection of proper materials for the job and the abilities for metals to withstand excessive forces that they were not designed to do if that counts.

I say the 4% or so difference in pressure between the No.4 chambered in 303

British

and the 308Win is not enough to worry about it. Actually its so trivial that if I was to mention this to anyone I know with decades of experience working with the properties of materials that they'd tell me I'm a idiot. Not a personal insult to anyone, just a fact. No design is within 4% of breaking or failing.

13,000 PSI is a lot more than 4% of 49,000 PSI.

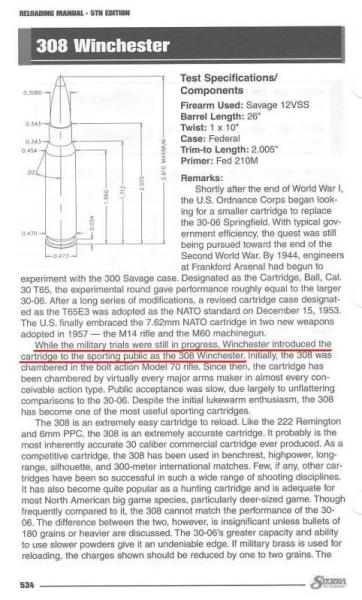

No one would, that is being stupid, look at your reloading manuals I doubt any 308Win max load will reach 55,000PSI. Now look at that same reloading manual where the Winchester Short/Super Short Mags and the Ultra Mags are listed as 62,000PSI loads.

Dimitri

Reloading manuals are suggested safe loads, they don't mean that no factory ammo can exceed those suggested loads. As Ed's post above shows pressures can vary by thousands of PSI within the same lot.

One can load a cartridge to as low a pressure as they wish.

55,000 PSI is over ten percent higher than any loading deemed safe for the .303. Also loads tested with one brand of cases can generate much higher pressures if a different case with smaller case capacity is used.

The 7.62 NATO chambered rifles would be safest if used only with taylored handloads that did not exceed the 49,000 PSI Maximum SAAMI specs for the .303.

-

06-25-2009 04:21 AM

# ADS

Friends and Sponsors

-

Legacy Member

I have reloading data from IMR for the .308 where 4 of the loads are shown to be 59,000 PSI (transducer). You have to remember those loads will have some statistical variation and some individual rounds will have higher pressure than the 59,000 PSI. (transducer).

But for Europeans with rifles that would be chambered and proofed to .308 the proof pressures are much higher. So much higher that I am not sure a #4 would pass or even survive.

US proof requirements for the .308 are 83,000 PSI to 89,000 PSI (by transducer)

And yes Winchester IS the final design authority for the .308 Win cartridge.

SAAMI is the standardizing body but Winchester OWNS the design.

Last edited by ireload2; 06-25-2009 at 09:20 AM.

-

Thank You to ireload2 For This Useful Post:

-

Banned

When the 7.62 NATO first came into being it was expected that military rifles already in existence would be rebarreled to this chambering, so there was good reason to keep chamber pressures to the same levels common for rifles of WW2 vintage. Purpose built 7.62 NATO caliber rifles benefited from advances in both design and metalurgy so as the older converted rifles were phased out, and as far as I know only a few French sniper rifles built on the MAS 36 action are still in service to represent the circa WW2 rifle designs converted, the allowable pressures for cartridges could be increased.

sniper rifles built on the MAS 36 action are still in service to represent the circa WW2 rifle designs converted, the allowable pressures for cartridges could be increased.

Much the same fits with the higher pressures of .308 chambered sporting rifles. Modern sporters built to handle the highest pressures encountered , at least for the much less abusive service of sporting uses, are known for their strength and designed in safety margins.

I have a low opinion of the quality of much of todays gunmaking, but some of the commercial sporters still available are true classics of strength and safety, much of their design being derived from those earlier rifles known for great strength such as the best of the Arisaka rifles a rifle respected for its strength. Arisaka safety features were incorporated into the Savage 110 actions for example.

rifles a rifle respected for its strength. Arisaka safety features were incorporated into the Savage 110 actions for example.

There are probably lower quality sporters built during the 60's that aren't up to extended use with the highest pressure .308 loads now available, and Mauser conversions, even those built on 98 type actions, that are marginal in this regard though the 7.92X57 is in the same class as the 7.62 NATO.

Add wear and tear, erosion and corrosion, and some rifles that are safe enough with low end .308 loads may be very unsafe with high end .308 or 7.62 loads.

The sparse information available on instances of LE boltheads being blown out. or broken with the extractor becoming a high velocity sharp edged projectile, suggest that when this happens bystanders are as likely to be injured as the man pulling the trigger.

I've examined about a dozen very nice looking Lithgow No.1 rifles that I suspect of being Cadet rifles of some sort, these had very good bores, probably rebarreled, and each and every one of those that still had its numbered to the rifle bolt body had the bolt head loose as a goose and the damage appeared to be more to the front end of the bolt body rather than to the bolt head. The bolt heads were most likely replacements. How this came about I can only speculate. It is likely these rifles were damaged by use of unsuitable ammunition, probably MkVIIIZ. Damage to these rifles makes it more plain why the Lithgow was considered unsuitable for conversion to 7.62 NATO. The receivers held up fine by the look of them, but the bolts had taken a severe beating.

No.1 rifles that I suspect of being Cadet rifles of some sort, these had very good bores, probably rebarreled, and each and every one of those that still had its numbered to the rifle bolt body had the bolt head loose as a goose and the damage appeared to be more to the front end of the bolt body rather than to the bolt head. The bolt heads were most likely replacements. How this came about I can only speculate. It is likely these rifles were damaged by use of unsuitable ammunition, probably MkVIIIZ. Damage to these rifles makes it more plain why the Lithgow was considered unsuitable for conversion to 7.62 NATO. The receivers held up fine by the look of them, but the bolts had taken a severe beating.

The out of spec action I've mentioned earlier came from that lot, It had a replacement bolt and had seemed tight enough with no overturn of the bolthead. If I'd examined the bore more closely I'd have not bought that rifle, but having examined the others I had assumed wrongly that it also had very good bore and was only crusted with fouling that could be cleaned up.

When I realized just how bad that bore was I obtained a replacement barrel intending to rebarrel and restore the rifle. The barrel was extremely difficult to remove according to the smith I engaged for the work. The shank of the old barrel looked to have swollen a bit. The new condition replacement barrel would not clock into that receiver.

I then began looking into sporting calibers suitable for the No.1 action and found few that were of the proper size for the action and still within safe pressure range.

-

Banned

-

Banned

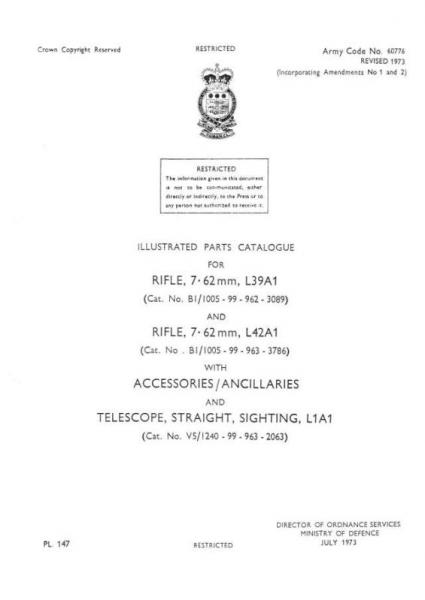

Does anyone need the parts manual for a inherent weak design.

-

Legacy Member

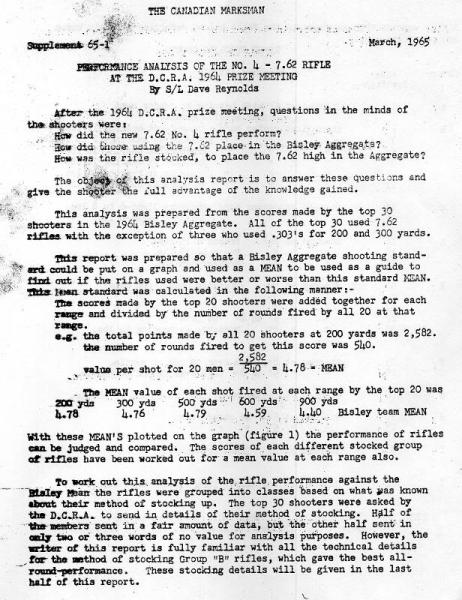

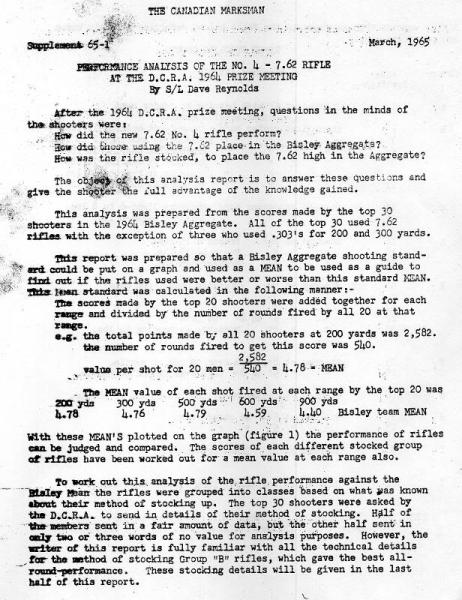

The Bisley team didnt seem to have any problems, and then seemingly the Canadian 's took No4s in 7.62 'on board' - any reported problems ?

's took No4s in 7.62 'on board' - any reported problems ?

The Meeting obviously covered up the fact that all 30 riflemen using the No4 in 7.62 were injured as their 'inherently weak' rifles burst using Mil spec 7.62 ammunition

Then of course the Enforcer, Envoy family came out in the early 70s - heavy 7.62 barrel but a standard No4 action.

- any reported problems ?

(Ed - I already posted the L39 L42 parts list in the library via Badger.)

-

-

Banned

And what our “inherent weakness” experts forgot is the 7.62/.308 case due to much less body taper and increased shoulder angle than the .303 generates LESS bolt thrust or force and strain on the action. (The old dry and oil free chamber trick ala P.O. Ackley)

The L-42 also has tighter headspace standards than the U.S. SAAMI standards for the .308 or the U.S. military headspace standards for the 7.62.

-

Banned

-

Legacy Member

Originally Posted by

Edward Horton

Alan de Enfield

(Ed - I already posted the L39 L42 parts list in the library via Badger.)

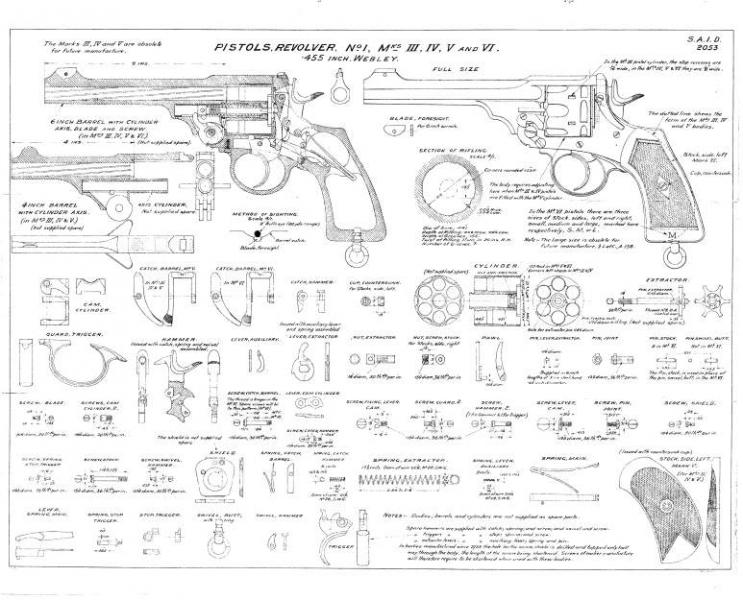

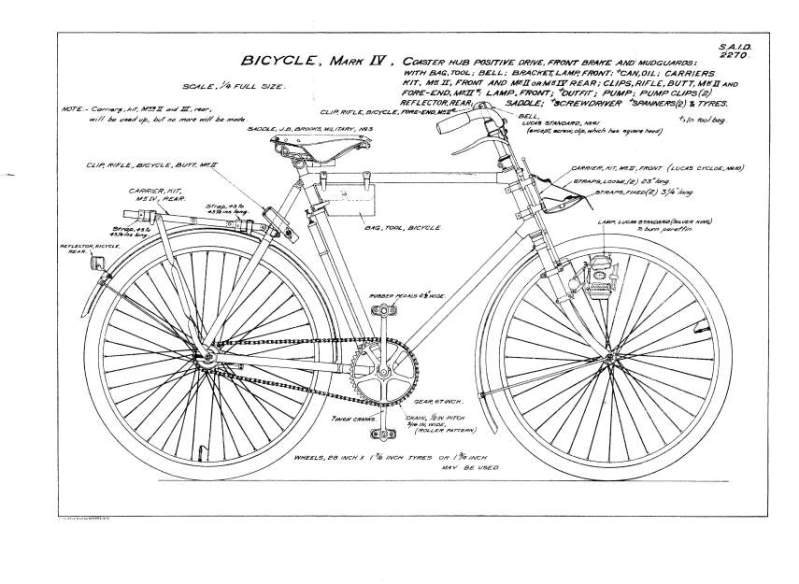

I call and raise you a Webley and a Mk. IV Bicycle SAID drawing

Take the 'pot' - Your Pair beats my Ace high !!!

-

-

Advisory Panel

Gentlemen,

I for one, am getting tired of an endless argument based on dubious figures.

Some of the values presented appear to be downright wrong. I don't know this SAAMI guy, but I am on good terms with Mr CIP. And here are the CIP figures for 303 British and 308 Win (no mention of NATO 7.62x51 to be found)

and 308 Win (no mention of NATO 7.62x51 to be found)

............303 British ... 308 Win

Pmax 3650 bar ... 4150 bar

PK .... 4198 bar ... 4773 bar

PE .... 4560 bar ... 5190 bar

The 308 Win values are a touch under 14% higher than the 303 British values.

I do not understand where the huge differences mentioned by some forum members have been taken from. And on this side of the Atlantic we are a bit puzzled by this arcane differentiation between 308 Win and 7.62x51 Nato. I suspect that there is some very doubtful information being thrown into this argument.

Nevertheless, a 14% increase may be considered to be a non-trivial increase in the stress on an Enfield No. 4 system. This increased stress will cause increased strain which may well reduce satisfactory operational life. That is in no way an "inherent weakness" of the original design for the 303 cartridge, long, long before the 308 was developed.

The bad, because unscientific, phrase throughout this saga is "inherent weakness". A rifle design that is too weak to fulfil its specified task with satisfactory performance, reliability and adequate operational life may well be said to have an inherent (design or manufacture) weakness that must be corrected for the design to be satisfactory. Early Springfield '03 receivers with faulty hardening certainly had an inherent manufacturing weakness. It was accordingly investigated and corrected.

Gentlemen, you are arguing round in endless circles and will never agree, because you are arguing from incompatible data. Couldn't you just agree to differ, politely?

Patrick

-

Thank You to Patrick Chadwick For This Useful Post:

Register To Reply

Register To Reply