-

Banned

Info for Alan de Enfield (and all others)

-

03-01-2010 06:36 PM

# ADS

Friends and Sponsors

-

Banned

Is there a reason this posting is being moved to another forum when it supplies additional information relating to two separate postings in this forum by Alan de Enfield below?

(Alan de Enfield) More Bad Press For The Enfield

More Bad Press For The Enfield - Military Surplus Collectors Forums

(Alan de Enfield) NRA RE-Issues Enfield 7.62 Warning (Jan 2010)

NRA RE-Issues Enfield 7.62 Warning (Jan 2010) - Military Surplus Collectors Forums

-

-

"Fatigue failure" here I don't think would of huge concern as unless the action is under strength enough to have a failure in a few thousand cycles, then merely changing bullet weight or for that matter, cartridge, would not move the probable failure point upwards by any significant degree.

Generally, acceptable "f.f." limits are set at the 100,000s or (10)6 cycle level to be considered safe in most stressed structures. Mostly because the failure point is hard to define w/in a factor of ten or so due to other variables that influence each individual unit. (Modern computer modeling can help here, but still!)

Additionally, microcracking is almost always started at or near the surface, so dye penetrant or magnetic particle testing can be used to check for problems well before total failure occurs.

So, if you're worried, get it checked. However, past history IS a good indicator of future performance in this case, so I believe fears from this failure mode to be groundless. I think regular old wear will render the rifle U/S before this point.

Last edited by jmoore; 03-02-2010 at 01:37 AM.

-

-

One rifle that seems to have an unusually low "fatigue life" is the FAL et al.

Seem to remember published failures being noted starting at roughly the 40-50,000 round limit. Life was doubled by changing the method of producing the raw receiver, but I 'll have to go back to Stephen's book and refresh memory.

M9 pistols suffered from a horribly low life limit, but it was discovered early in its life cycle, so changes were made. No such drama was associated w/ any of the Lee Enfield derivatives of which I'm aware.

ETA:

Another example. Early Glock 17 slides would fail through the ejection port RH side at around the 100,000 to 125,000 round mark, invariably cutting across the post finish (and hardening step) proof mark. Moving the proof raised the failure point to roughly 250,000 rounds.

The point here is that the load path, Although a bit more assymetrical than a No4, is similar in concept. The pistol would CONTINUE to function even w/ the RH side completely fractured, although POI tended to shift.

Last edited by jmoore; 03-02-2010 at 04:32 AM.

-

-

More thinking whilst running the machine:

Probable failure order of a No4's structural components:

1.Bolt head-

A)first excessive overturn (common)

B) then, fracture at the thread terminus (No No4 examples on hand, but I've several SMLE bolt heads broken off at this point.)

2.Bolt -

A) Forward face wear takes out most of these, I think.

B) Also the small lug in the striker cam area sometimes fractures- seen a few of those.

C) Bolt lug wear

D) Bolt lug shears off LH side - Never seen or heard of it though!

3.Receiver Body-

A)Bolt lugs wear through the hardened mating surfaces- Caught upon inspection- no real danger here.

B) Fatigue failure of RH receiver rail. Rifle contiues to function-sort of -probably begins to bind up on cycling and POI/accuracy go out the window.

C) LH receiver wall fails- a bad day! But there ought to be all the warning signs above.

Pure speculation, though. Tear this argument to shreds if y'all wish!

-

Thank You to jmoore For This Useful Post:

-

Banned

-

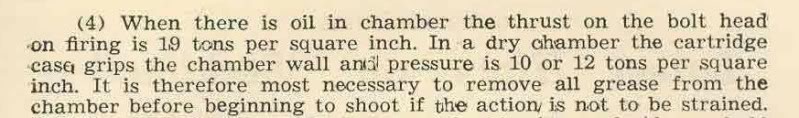

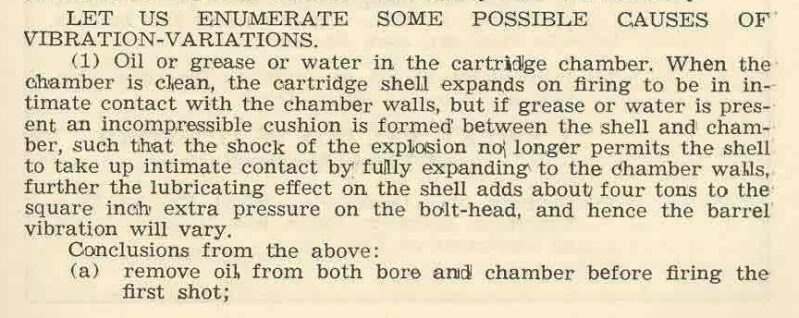

Reduced power loads often back out primers as the primer upon ignition pushes the case forward, but there is not enough pressure (or the case grips the chamber walls) to "reseat" the primer. I've seen this in plenty of other rifles (w/ good to tight headspace) than Enfields, as have you, I suspect.

You still haven't figured out why this thread is "out here"?

-

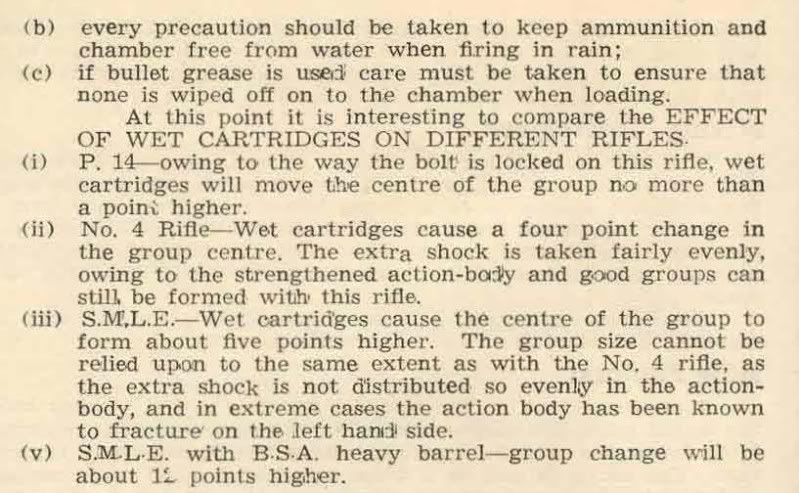

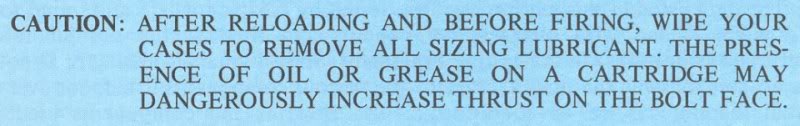

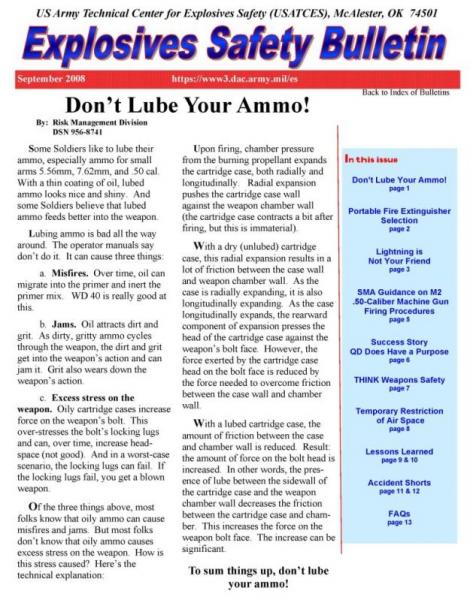

BUT the information below applies to all firearms no matter what country they are made in.

)

144 grain load puzzled me. This is because the chamber pressures for ALL bullet weights in a given caliber are set at the same approximate chamber pressure. And to be blunt I thought this bullet weight limitation was so much garbage.

Register To Reply

Register To Reply