-

Contributing Member

Waterbury Buckle Discontinued Hooks for the M1907 Sling/Our New Dies Are Finished

Turner Saddlery, Inc.

Well it happened again, called ITW Waterbury Buckle back in early February to place an order for M1907 Sling Hooks/Frogs, and discovered they had split and reorganized, discontinuing the hardware I had been buying for over 20 years. Not only did they discontinue the part, they scrapped the dies. Back in 1992, Waterbury bought out Brookside Manufacturing Corp. who was a military hardware contractor, and my first supplier for the hooks. Prior to the buyout, I along with another company contracted Brookside to make new dies since there original WWII dies were worn out.

Sad thing is, ITW Waterbury Buckle was one of the only manufacturers left that were producing the majority of older metal hardware for slings, such as the M1923 Sling and the M1 series of web slings. This includes the cam buckle, spring clip w/"D" ring for the rear swivel, and "N" buckle. Hope there is another manufacturer who produces these because it will hurt the web market, and I would hate to find out how much new dies for these parts would cost. I was told they had made changes and were geared more to the Clash hooks for the newer web slings. They scrapped a lot of dies and tooling, and moved Waterbury Buckle from Waterbury, CT to Broadview, IL. ITW Plastiglide is now located in their old plant in Waterbury, CT.

series of web slings. This includes the cam buckle, spring clip w/"D" ring for the rear swivel, and "N" buckle. Hope there is another manufacturer who produces these because it will hurt the web market, and I would hate to find out how much new dies for these parts would cost. I was told they had made changes and were geared more to the Clash hooks for the newer web slings. They scrapped a lot of dies and tooling, and moved Waterbury Buckle from Waterbury, CT to Broadview, IL. ITW Plastiglide is now located in their old plant in Waterbury, CT.

This is the second time over the past 25 years that this has happened. I lost another set of dies that was designed to punch a very distinctive brass hook used during WWI and was also appropriate for the M1887 Sling. Same story, company went out of business and dies were scraped before I found out, no notification on their part.

We have just had another set of punch and forming dies made. Fortunately a relative owns a tool & die shop locally and just completed the dies last week and after twice losing dies, I will keep a tight rein on these since they are in house. At the moment all our hardware will be made right here in Alabama except for our MILSPEC 13 gauge brass rivets which are made in the North East on our dies. We send the rivet dies out with the order and have them returned when the order is completed.

The hook dies were not cheap, but they are correct and the hooks/frogs, will have a smooth edge on the face of the hook, where as the progressive dies that Waterbury was using (blanked two hooks at a time to reduce waste), double blanked the hook, leaving a burred edge on half of the face of the hook. Our dies are progressive, but a little more handling per hook during the forming process.

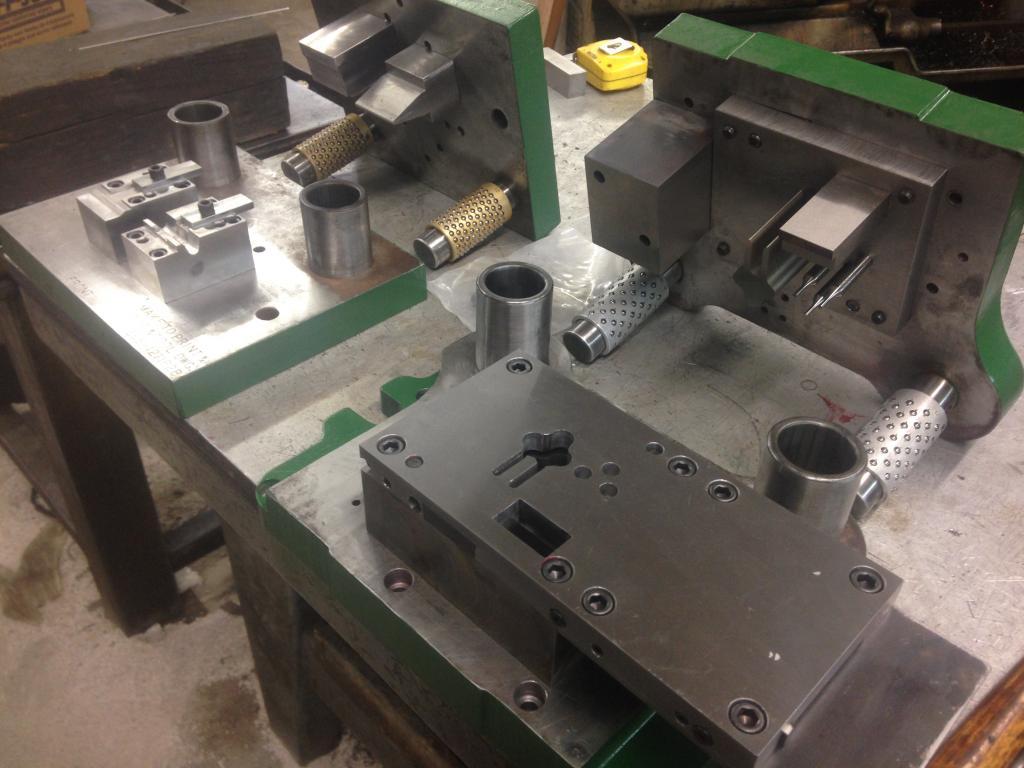

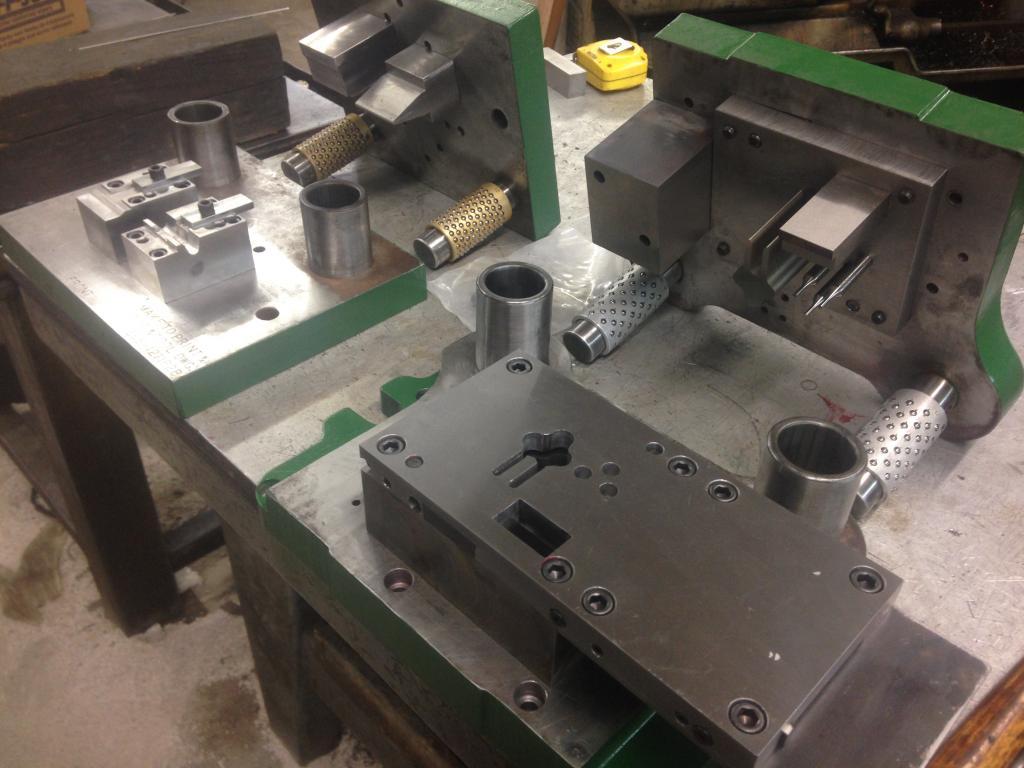

Here are some photos of the new dies and some blanked out hooks. Haven't had a chance to form the samples at the moment, but we will test the forming dies and heat treat once it is determined if any adjustments need to be made. My cousin Kevin Lumpkin of Lumpkin Tool & Die has performed yeoman's work in designing the new dies per Rock Island Arsenal Drawing #7137567 which calls for .105 material with .109 diameter hole. We will be able to turn out both brass and steel hooks/frogs on the new dies.

We are still a family run shop, only three of us, myself, wife Camille, and son Stuart age 17. We are still operating out of an addition to our old barn here in Clay, Alabama. A lot of the equipment I use here in the shop to turn out M1907 Slings either came out of one of the arsenals or is the same make and model vintage equipment that was used during WWI and WWII. All the leather M1907 Slings have the correct oblong holes and are punched on vintage reciprocating punch presses identical to the ones Boyt used during WWII. I have traveled the country over the past 25 plus years acquiring the vintage equipment we use everyday in the shop. But the most difficult part has always been hardware suppliers, two rivet companies and three hardware companies have either closed their doors or discontinued the hardware over the past 25 years. Kevin built the dies, but I guess I'll have to spend time at his shop punching parts and then Parkerize them just as I have the "D" rings for years.

Semper Fi,

Richard

Here is a photo of a M1907 sling using customers original WWI brass.

Our rivets are made to the original MILSPEC from 260 cartridge brass #13 Gauge wire on a button head wire forming machine as were the originals. The rivets are set using a rivet hammer and anvil as were the originals.

All equipment use to produce the slings are the same models and make as were used by Rock Island Arsenal, Boyt, Hickock, Enger Kress, ect.

Our creasing machine is a Randall Harness Mfg. 1887, and was one of the models that was used at the various arsenal harness shops. It has been documented as having come out of one of the arsenals, just don't know which. One of the key features to this machine is it is built backwards from the civilian models of that era, so it is easy to distinguish. It rolls the back (flesh) side of the sling and roll presses the crease down both edges of the sling on the grain side. This is a two step operation.

The sling is sewn with a Campbell Harness Stitcher (Needle Awl Machine) (Circa 1890s) serial number is in the range of some of the Campbells that were sold to the Ordnance Dept. in that era.

Our 18" fixed blade splitter was made by the International Harness Co., Cincinnati, OH, mfg in the late 1870s. Is has an arsenal inventory data plate braded to the cast iron frame, just don't know which arsenal.

Our punch machine is an Alva Allen 5ton, equipped with a cam operated reciprocating attachment, which indexes the strap for each pair of holes. I use three of these machines (set up for various operations), and they are identical to the ones Boyt used during their WWII production. These machines have been dated to the 1930s. All holes are the correct oblong type as on the original slings.

The thread used is NOS natural linen (wheat color) 8/4 MRT Left Twist, waxed as it passes through the machine.

Semper Fi,

RT

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

Last edited by Badger; 07-30-2014 at 08:41 AM.

-

The Following 11 Members Say Thank You to Richard Turner For This Useful Post:

A. F Medic,

Bob Seijas,

Brian Dick,

gsimmons,

HOOKED ON HISTORY,

jmoore,

Joe W,

longebow,

Mark in Rochester,

Rick B,

Sarge1998

-

07-27-2014 07:22 PM

# ADS

Friends and Sponsors

-

Contributing Member

This is some additional information as to how I got my start. Didn't have much put together as a bio, but received several PMs from the CMP Forum members asking how I got started in leather so this is what I have reduced to writing for now.

Forum members asking how I got started in leather so this is what I have reduced to writing for now.

Also, many thanks to you, Mr. Seijas , always enjoyed the conversations when we would see each other at the GCA

, always enjoyed the conversations when we would see each other at the GCA Conventions in years past. Dick Culver

Conventions in years past. Dick Culver was how I came to know about the GCA as well.

was how I came to know about the GCA as well.

Semper Fi,

Richard

----------------------------------------------------------------------------------------------------------

Many thanks for all the support, it gets harder and harder every year for a small business to keep going.

I ask for forgiveness in advance for such a long piece; however, if one doesn't have the time, it need not be read. I just feel compelled to dispel some myths, untruths, and recognize many who have been of great assistance and help through the years. If I have left out anyone, I apologize.

Over the years, I have watched many of the talk forums, and have rarely posted, kind of like a fly on the wall as some would say.

First off and above all, I would like to recognize my Mom, Kay Turner, who worked with me in the shop from 1994 to 2011, until her health began to fail. Many had the opportunity to talk with her on the telephone over the years, from anything to placing an order, or having questions answered. Some customers enjoyed her personality so much she said guy were calling just to say hello. She even had some calling, asking for "Granny Kay", as she was known to family and friends. She was just that way. Many probably don't know, but we lost her to leukemia two years ago.

Back when I first got serious about turning out rifle slings, 1988, I had already been making holsters, cuff cases, and belts for fellow agents I worked with in CID and NIS (now NCIS) while I was stationed at Lejeune and Pendleton (made my first holster at age 14). I rebuilt many saddles while at Pendleton (MWR base stables) and the old McClellans the base color guards were using.

The first real old time saddle and holster maker I had a chance to learn from was Mr. D.W. Smith, who had an old time saddle shop in Mira Loma, CA, (Riverside County). D.W. was in his eighties at the time, and had made a lot saddles and holsters for many of the old "B" Western stars, such as George "Gabby" Hayes, Texas Ed, Noah Berry, Charles Starret (The Durango Kid), Lash LaRue, and many others. Man that was right up my alley. D.W. had a photo album with autographs and letters of thanks from all the western stars for holsters and tack he had made for them over the years. I wish I had paid more attention to saddle making, but was primarily interested in old west holsters. I spent many a Sunday with D.W. in his shop, which looked like Judge Roy Bean's Saloon/Courthouse in Pecos, TX. I remembered when I showed D.W. one of my first M1907 slings, he was almost offended. He thought I was backing up, and said "Son, that's what beginners start out with, your not going to make any money that way".

When I returned home to Alabama, I tried to stay in contact with D.W., and after a year or so lost contact with him. They eventually bulldozed down his saddle shop to widen the highway. Through D.W., I was able to meet Gene Autry and Roy Rogers, and spending time with Dusty at the museum. Had a deal to reproduce one of Roy's rigs, but was never able to keep the cost low enough for sale in the museum.

I also got to meet John Bianchi and spend many days at the factory. Mr. Bianchi was always willing to answer questions and point me in the right direction for hardware and leather. Through Mr. Bianchi, I first learned of Hermann Oak Leather. Remember, there was no internet to speak of in the mid eighties. He had a huge reference library of every leather and hardware related catalog that was available, especially since he was heavily involved in military contracts. That is how I located the hooks for the M1907 that Brookside Manufacturing made, (later bought out by Waterbury).

The upstart of making the M1907 was also due in large part to Gus Fisher, MGySgt USMC Ret., who was the Team Armorer at Edson Range in the late 80's. Gus and I met one day while I was in Ransbergers Cal Custom Gun Shop, Fallbrook, CA (I also lived in Fallbrook). I told Gus I was interested in building the M1907. He invited me out to the range where he gave me a handful of old salvaged hooks and loops. Gus was already working with leather at that time. In 1989, I approached Maj. Jim Hill, USMC Ret., owner and founder of Creedmoor Sports, Oceanside, CA. Major Hill gave me the first shot at going commercial with the slings. I had to go this route since it was starting to become a conflict of interest, what with being a CID Agent and active duty Marine, having supply sergeants and supply officers calling the CID Office asking for the Marine who makes service slings. Major Hill saw my predicament and said he would stock the slings so as to keep me from going to the brig. I really have to give kudos to Major Hill, great man to work with (at times I think I was working for him). In the beginning I was making the M1907 with a 50" long strap. It was Major Hill's idea to make the sling longer, especially since the Division Matches were beginning to use the M16A2 rifles. He then asked that I make the slings thicker. It was also his idea to number the adjustment holes, as he said it would help and bolt gun slings were already numbered. He also suggested making the keepers wider than the 5/8" or 3/4" width, which is what was mostly encountered on the MRT contract slings, so at his suggestion, I went with the 7/8" width.

Then comes the thickness issue, it has been discussed many times on many forums, but I will never make a sling thicker than the legal limit in accordance with CMP/NRA rules and regulations, which is 3/16" (12oz leather). I gauge every hide to make sure it is to spec. One reason is, I don't like the thought of a shooter attending one of the sanctioned matches and getting disqualified for a sling being too thick. I have seen it happen in the early nineties at Camp Perry, and have talked to a few shooters who got bumped at a local match. To me, I would rather follow the rules, plus I don't want to run the risk of getting sued, heck, fast food joints are getting sued for serving coffee too hot. Some people will sue over anything, just watch the news. The way my luck goes, if I made a sling over spec, I would be the one who gets popped with a lawsuit, taking into consideration all the money, time, and travel involved in getting to the Nationals and finding out your disqualified for having a sling that is too thick or keepers too wide. I don't know, maybe these rules are not enforced as strictly as they used to be. I have seen on other forums, those who have said "they like a heavy sling", "that it is a petty rule anyway", and that "one would probably not have any problems at local matches", but "they might rethink using a heavy sling if they went to Perry".

The whole issue of thickness and keeper width is how I come to know R.O. Dick Culver, Major USMC Ret. I had a shooter come in the shop in the mid-nineties, who had just returned from the Nationals at Camp Perry. He said he had been disqualified for using a sling that was too thick and keepers that were too wide and large (was not one of mine). I told him I would call up to Camp Perry and see if I could get some information for him. The lady who answered the phone said she would find someone to help, it was Dick Culver (he was working for Colonel Willis). That was the first time I had talked to Dick. Didn't really know who he was at the time, but got educated real fast, Dick said the current CMP regulations were that a M1907 sling strap could be no thicker than 3/16" and the keepers had to be 3/4" wide or less. I informed him that I had been making the keepers 7/8" wide for 5 or 6 years. He said it was not legal and to change the keepers back to 3/4". I asked what would I have to do to get a review, and he stated the only way was if it was deemed as issue equipment. I told him that various service units and supply organizations, including the Marine Corps Team at Quantico had been purchasing the slings with the wide keepers for years. He said are any in use by combat units, and I said they were being used on the M40A1 as a kit sling, and the Army and Navy had bought the slings in limited quantities. I provided him with a DOD Cage#, and the issue went up for review and the keeper width was approved for the 7/8" width. Once Dick and Gloria returned to Idaho, we connected again, attending many shows across the country, GCA Conventions, as well as the Soldier of Fortune Convention in Vegas. We became life long friends with Dick and Gloria, and both have been very instrumental in helping us get to where we are today. Sure do miss the Major, as most know he passed away back in February. Through Dick Culver I met a lot of folks who I would never of had the opportunity to meet otherwise.

All of our NM slings are 10 to 11 ounce thick (leather thickness is measured in ounce weight, one ounce equates to 1/64"), with a half ounce MILSPEC variance. Our leather once it is cut into strap form is pre-stretched and broke in by hand, then moistened and ran through a combining machine, which has two heavy rollers to even out the thickness and to reduce stretch, this machine is approaching 100 years old. This allows one to start with a strap an ounce or so heavier and reduce it down in thickness while at the same time eliminating as much stretch as possible. Also, every M1907 type sling we make has to meet the guidelines of the Berry Amendment/U.S. Compliance Code in order for us to compete in open purchase contracts.

During this same time frame, it was my idea to start stamping NM on the service rifle M1907 Slings, to easily differentiate them from the standard issue M1907. I was contacted by one of the snipers who worked for the San Diego PD Swat Team, who suggested I start dying the NM version black and I should call it the "Poilce Tactical Sling", I went with his suggestion and the sling took off. His reasoning was that the police departments would not be interested in a sling that had a military connotation, too militaristic he said, (boy, departments sure have changed today).

I had shot several times with Norm Chandler, LtCol USMC Ret. (mid 80s), who was at that time a Major and XO of Weapons Training BN, Quantico, VA. I contacted LtCol Chandler while he was CO of Stone Bay, Camp Lejeune, NC, he had already started Iron Brigade Armory in anticipation of retirement. He was also a great influence in regard to technical support and the needs of the sniper community. I sent LtCol Chandler some of my first M1907 slings and that relationship continues today.

I used to attend many gun shows in the SoCal area and one weekend, I had a sack full of slings and met Ken Fladrich, who later opened the Armory of Orange with Mike and Dave, Ken was kind enough right on the spot, to let me share table space at the Great Western Show in Pomona, CA. I also had a lot of assistance from Mr. Lu De Le Fortrie, who is very knowledgeable in U.S. Military accoutrements and a collector of military sniper rifles. We continued to set up at shows together while I was based at Pendleton. My first big opportunity as far as holsters go, was to meet John Terlesky, an actor in the CBS series "Guns Of Paradise" and made several period western rigs, one of which he used on the show.

Once I returned home in 1991, I set up a full size saddle & harness shop, but slings seemed to be the mainstay. I soon became acquainted with and friends of Thad Rybka of Thad Rybka Custom Gun Leather and Ken Campbell of KC Custom Gun Leather, both locals to my area. They were already master holster makers in their own right, and both have had their holsters featured in most of the major gun magazines. We visit each other often and trade ideas and share common problems within the trade.

I made over 100 U.S. M6 Scabbards for the M3, for the movie "Saving Private Ryan" We did have a shot at about 6,000 slings for the movie, but there was no way, as they needed the slings on site in Ireland within eight weeks. Looks like they used the outfit that makes the slings with the thin gilt plated hardware and tubular rivets, it is definitely noticeable when watching the movie.

I apologize for such a lengthy tome, but the wife says I talk too much anyway and it probably carries over to the written word as well.

Regards

RT

Last edited by Richard Turner; 07-29-2014 at 07:32 AM.

Reason: typos

-

The Following 13 Members Say Thank You to Richard Turner For This Useful Post:

Bill Hughes,

Brian Dick,

gsimmons,

HOOKED ON HISTORY,

jmoore,

longebow,

rayg,

RCEMERalf,

Rick B,

Sarge1998,

teltec01,

tom gray,

WarPig1976

-

-

Legacy Member

What an interesting read, thank you. I thoroughly enjoyed it and the effort you went through to develop a quality product., Ray

Last edited by rayg; 07-29-2014 at 08:35 AM.

-

Thank You to rayg For This Useful Post:

-

Contributing Member

Great story! Thanks for all you do for us.

Tom

-

-

Contributing Member

-

The Following 3 Members Say Thank You to Richard Turner For This Useful Post:

-

Advisory Panel

Not sure if I can be asking this here Richard, but are parts like the brass rivets available to us? I have encountered broken rivets from time to time.

-

-

Contributing Member

Not sure if I can be asking this here Richard, but are parts like the brass rivets available to us? I have encountered broken rivets from time to time.

Sir, I don't usually sell hardware, but I am fairly set on rivets at the time. If you just need a few, feel free to give me a call. I don't have a price set, but I can come up with something reasonable to help you out. These are made to WWI and WWII MILSPEC and I have never had a problem in remounting decent quality WWI brass or WWII steel frogs on new leather. All the original frogs should have the required .109 dia. holes.

RT

-

-

Hello Richard …

Thank you for your posts, as well as describing your entrepreneurial experience in growing your small business. Personally, I enjoyed the pics and videos showing the various manufacturing techniques.

However, I have moved your thread to the Commercial Auction and Sale “Gossip” forum, as it borderlines somewhat on business solicitation and advertising. We have received some private email complaints from members and paid advertisers, who point out that your company financially supports other guns sites, but not this one.

I have no idea whether this is true or not, but I would ask that out of respect to our paid advertisers who directly aid in keeping our site going through their “banner” support, that you keep your posts to an educational focus in nature.

Having said that, I’m sure we would all enjoy seeing more videos and pics of the manufacturing process and how your products are made.

Thank you for you consideration…

Regards,

Doug

-

-

Advisory Panel

Hi Richard! Welcome to the forum!!

-

-

Advisory Panel

Originally Posted by

Richard Turner

If you just need a few

Yes sir, that's exactly it.

-

series of web slings. This includes the cam buckle, spring clip w/"D" ring for the rear swivel, and "N" buckle. Hope there is another manufacturer who produces these because it will hurt the web market, and I would hate to find out how much new dies for these parts would cost. I was told they had made changes and were geared more to the Clash hooks for the newer web slings. They scrapped a lot of dies and tooling, and moved Waterbury Buckle from Waterbury, CT to Broadview, IL. ITW Plastiglide is now located in their old plant in Waterbury, CT.

PM

PM

[/URL][/IMG]

[/URL][/IMG]