-

-

The Following 3 Members Say Thank You to louthepou For This Useful Post:

-

10-18-2011 07:11 PM

# ADS

Friends and Sponsors

-

If I could be so bold as to bold and daring as to pass comment Lou, could I humbly suggest that the slip patch (as we called them) could be a little longer - could I say, 1/2 length again overall. While hard oak isn't a good patching wood of itself, it is superb/the best for slip patches and dowel pegs. Mind you, while oak isn't a good patching wood, it does make a lovely set of bayonet grips for a No1 bayonet

-

The Following 2 Members Say Thank You to Peter Laidler For This Useful Post:

-

-

One bit of advice I would offer is that I've always ran the slip patch grain perpendicular to the grain of the hand guard. Less likely to split again that way.

Союз нерушимый республик свободных Сплотила навеки Великая Русь. Да здравствует созданный волей народов Единый, могучий Советский Союз!

-

Thank You to Claven2 For This Useful Post:

-

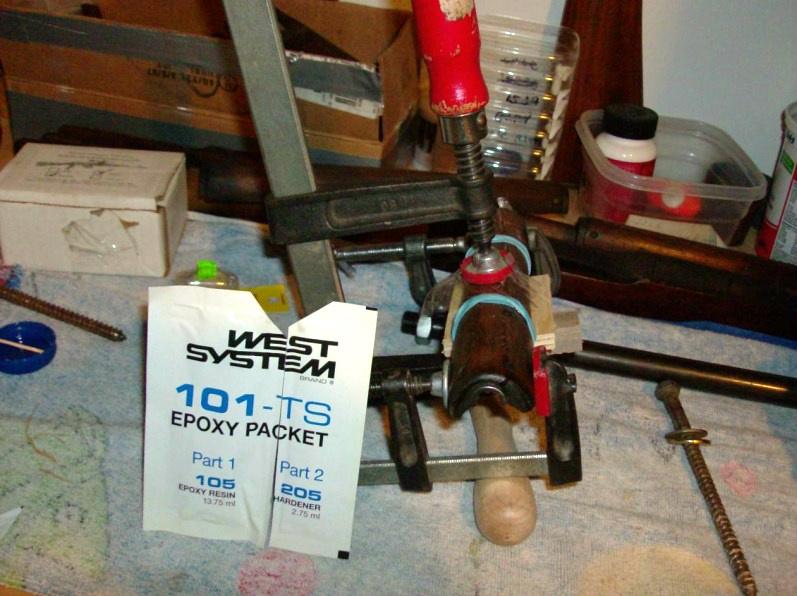

Peter, Claven, thanks for these very good tips. I did think about the grain, but only once it was glued! (beginner mistake... I'm learning!)

"Slip Patch" - I was wondering what these were called. Thanks Peter. I saw many of them on No1Mk3* rear handguards, figured it was the right repair for this kind of split. Oh and, please, feel free to be bold and daring any time you want! I thrive on constructive feedback, and I know I am priviledged to have access to so much knowledge.

-

-

The reason we slip-patch at an angle across the grain - so I was told as an apprentice - is that by going at an angle as opposed to across it, square, is that you'll get a LONGER slip patch and therefore more inherent strength at no extra cost. Whether a good woodworker or cabinet maker would agree with this is another matter.

You got any comments on the truth or fallacy in this TBone.......................?

-

-

going at an angle as opposed to across it, square, is that you'll get a LONGER slip patch and therefore more inherent strength at no extra cost.

Never heard it in a "class". But it makes sense. Plenty of other joints use this principle, the number one example that comes to mind is a scarf joint, Vs a butt joint. Absolutely no comparison is strength and joint stability, all coming down the different surface area achieved in gluing together pieces of the same section size (plus a little bit more stuff that gets a bit wordy).

Last edited by tbonesmith; 11-05-2011 at 05:01 PM.

-

:

PM

PM