-

FREE MEMBER

NO Posting or PM's Allowed

Bolt will not stay closed

Hi everyone,

I posted a few weeks ago about a No4 MK1 rifle that I picked up cheap at Canadian Tire. I mentioned that I was having a hard time closing the last inch or so of the bolt - I really had to use a lot of pressure to force the bolt closed. This is without even having a shell in the rifle.

Tire. I mentioned that I was having a hard time closing the last inch or so of the bolt - I really had to use a lot of pressure to force the bolt closed. This is without even having a shell in the rifle.

Today I took the rifle out, removed the bolt and cleaned the barrel. The rifling looks fantastic in the barrel still. I removed all the gunk I could from everywhere in the rifle and gave it a light oiling, paying special attention to the bolt and bolt seat. I then placed the bolt back in.

Here's the problem - the bolt now slides forward and closes with much less effort, but it refuses to stay closed. I will close the bolt, leave it for a few seconds, and it will pop open, flying at least 3/4 of the way back.

Did I oil it to much or break something? I could not keep the action closed long enough to aim, and I am afraid that even if I was able to fire it that the force of the shell going off would blow the bolt back into my face!

Any ideas? Thanks in advance.

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

05-01-2010 11:33 PM

# ADS

Friends and Sponsors

-

Banned

You need to download the Canadian No.4 manual Maintenance Instructions below and follow the inspection requirements.

No.4 manual Maintenance Instructions below and follow the inspection requirements.

1991 No.4 (All Marks) .303 Rifle Maintenance Instructions

1991 No.4 (All Marks) .303 Rifle Manuals (Complete Set) - Military Surplus Collectors Forums

I would dissemble the bolt and check and inspect the firing pin spring, the ends of the spring may be digging into the inside of the bolt and the collar of the firing pin causing excessive torque when compressed. And also the extractor spring for weakness or breakage (both could be causing the bolt to fly open)

On my Enfield's I normally replace the firing pin spring and the extractor spring because they are the most used and abused springs on your Enfield.

Follow the inspection requirements looking for defects like bolt head over rotation, weak springs and worn parts.

You are now your Enfield's best friend and armourer............read the manual.

Without photos we are nothing more than misinformed psychic Enfield mechanics.

-

-

Advisory Panel

I guess we better start at the start... Is the bolt head screwed right into the body before inserting it in the rifle?

Did you rotate the bolthead down and lock it into it's guide way on the right side of the receiver?

Is the bolt handle closing all the way down until the long rib on the bolt body touches the right side wall of the receiver?

Have you tried closing the bolt with the trigger pulled so it does not cock the rifle? if so, is it any different?

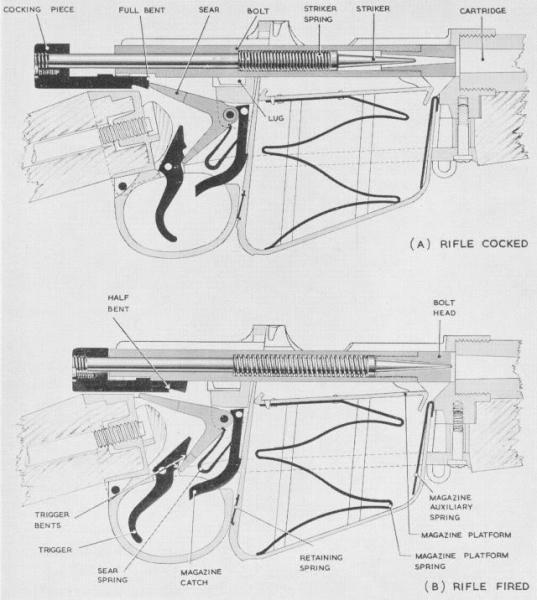

If all the above things are good, then the next thing to look at... there might be be a burr on the rear face of the striker collar where the mainspring contacts it and also at the rear of the bolt body inside. If so, the spring can bind and actually be "torque loaded" by the action of rotating the bolt handle down. In combination with oil on the locking lugs, this may be causing your trouble.

There'll be more guys check this out over the next few hours, so look in for more suggestions....

Hah! I just looked back in to see Mr Horton's "delayed reaction" posting... I'm sure it wasn't there when I responded... or was it...

Last edited by Son; 05-02-2010 at 07:55 AM.

-

Thank You to Son For This Useful Post:

-

Legacy Member

Sounds like you need to remove some of the lube from the bolt and inside the receiver.

-

-

Advisory Panel

Myself I was wondering how long it has been since Canadian Tire sold No4s!

Tire sold No4s!

-

-

Banned

-

Advisory Panel

If it is difficult to close "the last inch or so" of the bolt travel, then it sounds like the safety is incorrectly assembled - causing the cocking piece to bind or hang up on the (probably mangled) remains of the safety stop.

-

-

FREE MEMBER

NO Posting or PM's Allowed

Hi guys,

Thanks for all the help. Following the advice above I removed the bolt again and inspected the bolt head. It turns out that I had rotated it 360 degrees once before putting the bolt in. I rotated it all the way back, reinserted the bolt and it then stayed closed (and with pressure feels like it will stay closed now fine).

Time to go to the range and try to fire is now for the first time !

Thanks again!

-

FREE MEMBER

NO Posting or PM's Allowed

Windigo, I maybe over cautious, but if I haven't screwed the bolthead in all the way, it won't even close. This is a good case to test the headspacing (there's plenty of articles so perform a search).

Brad

Tire. I mentioned that I was having a hard time closing the last inch or so of the bolt - I really had to use a lot of pressure to force the bolt closed. This is without even having a shell in the rifle.

Register To Reply

Register To Reply