-

Legacy Member

When one resizes the brass be it full length or neck size only the brass stretches a bit each time at the neck. After a few times you have to trim it back to minimum spec. After a number of stretch trim, stretch trim cycles the neck thins out and eventually splits. There are things you can do to prolong brass life but it will wear out.

-

-

09-08-2013 04:55 PM

# ADS

Friends and Sponsors

-

FREE MEMBER

NO Posting or PM's Allowed

Do ppl find the no4 is hard on brass? everyone I talk to thinks so....P14 on the other hand is far kinder....

I seem to be the odd man out - I have serviceable brass over 30 years old. It neither stretches nor cracks. Neither does it expand at the web like that. The only case losses I've had over the years is to long grass. I never need to set the shoulders back either. I should hasten to add I do not load and fire them every day but some individual cases get used for load testing and those get loaded several times a day when I'm doing that.

Annealing often is a requirement for consistent neck tension so should be done after every three or four firings.

I've never seen an undersized case so I can't comment on that. Those cases may be thin wall so the very marked expansion ring could be explained but it looks like high pressure. The primer needs to be examined. It's not the outer primer radius so much as the firing pin indent radius. A primer that shows the outer radius is fine but one that is flattened only means it might have backed out and was reseated on firing.

My cases don't normally show such a dramatic expansion. I do have some very old cartridges and they show their age with tarnishing. One doesn't often see annealing stains on commercial brass - they get polished. Military brass doesn't. Apparently the military requires annealing stain because of the problem un-annealed brass can cause. PRVI brass comes with annealing stain.

Where the brass comes from when cases stretch is the web area where it weakens the case leading to case head separation.

I had some reformed military brass in 25-303, some of which were cracked with age. Those that weren't were pulled and annealed then reloaded with no problem. Those that were not pulled all split on firing. So it seems that if the cases can be annealed in time they are fine. (The factory that did the reforming did not reuse the cordite).

Last edited by 303Guy; 09-08-2013 at 05:31 PM.

-

-

Legacy Member

Originally Posted by

WarPig1976

When one resizes the brass be it full length or neck size only the brass stretches a bit each time at the neck. After a few times you have to trim it back to minimum spec. After a number of stretch trim, stretch trim cycles the neck thins out and eventually splits. There are things you can do to prolong brass life but it will wear out.

+1 on your post.

Re Reloads, if I didn't load it, I won't shoot it!

End of Story.

-

-

FREE MEMBER

NO Posting or PM's Allowed

Originally Posted by

Trung Si

+1 on your post.

Re Reloads, if I didn't load it, I won't shoot it!

End of Story.

Believe it! A friend bought a Lee Enfield and it came with some ammo. This friend happily started shooting this stuff off. He noted that some fired quite stiff while others were pretty mild. Well, this thing had severe excess headspace and although I advised him not to fire it he continued. Well, the rifled began to jamb until it was inoperable so he took it back. He gave me what was left of the ammo which I pulled. The powder wouldn't flow out the cases and some had a small charge and others full. Powder bridging in the powder hopper. For those that don't reload - the powder 'bridges' in the popper which holds back some of the powder then that amount plus the new charge get dropped into the next case. Now some people charge then seat a bullet. Bad idea because then these things don't get picked up. So, never use someone else's hand loads! Also use a powder that fills the case and at the same time has a slower pressure rise and moderate peak pressure.

stretch trim cycles the neck thins out and eventually splits.

Not really. Cyclic sizing and stretching work hardens the brass resulting in splitting. The brass comes from the web area mostly. In the process the shoulder creeps forward resulting in the 'doughnut' at the base of the neck. Full length sizing does that. The neck itself could get stretched and lose material on trimming.

The use of an expander ball draws the case forward too. A collet type neck sizer solves that.

Last edited by 303Guy; 09-08-2013 at 06:01 PM.

-

Legacy Member

Old ammo can suffer neck splits, just sitting in the box. This is mostly the result of insufficient annealing of the neck before bullet-seating. Brass, like a lot of other metals "ages". Seating a bullet involves forcing it into a neck that is "undersized" This puts a fair amount of mechanical stress on the neck and this stress may eventually lead to cracks if the crystal structure of the brass is not sufficiently "relaxed".

ANY case that has been fired even ONCE with a mercuric based primer WILL fail in fairly short order. The mercury in the priming compound is released as "free" metal vapour upon ignition and some of it IMMEDIATELY bonds with the brass. From that instant on, your brass is doomed as the mercury steadily disrupts the crystal structure of the brass causing embrittlement.

In the "old days", folk who understood this and had some smarts (and the primers), would strip down the Mk 7 ball ammo. The trick was to "neutralise" the primer before attempting to remove it; tossing the cases in diesel fuel for a few weeks is apparently one method. Once the mercuric primer was safely removed, (the hydraulic method is the safest and neatest), the case could be neck-annealed, reprimed using the RWS 6000 lead-based primer and reloaded, and reloaded etc.. A LOT of drama and a task only to be undertaken if you have bulk, very cheap Mk7 ball or very limited alternate ammo options.

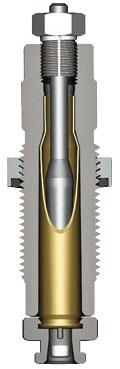

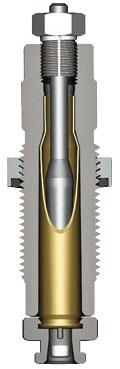

The other consideration is the chamber:

I have some data on "Mil-spec" .303 chambers and interestingly enough, the dimensions are not too dissimilar from SAAMI.

What I suspect is that a LOT of surplus rifles have had their bores "polished" and chambers "cleaned" for commercial sale. If some bozo has ripped into the chamber with a strip of 100 grit carbide cloth on a wobbly spindle mounted in a power-drill, who knows what evil has been done. It might LOOK all sparkly and "clean"........

Homework challenge:

It would be interesting to get a quick survey of brass measurements; HXP, Dominion, Winchester( Mil and "commercial"), Remington, Mk7 from sundry makers etc. and do a comparison with the SAAMI ammo spec. AND the published dimensions of SAAMI, Lee Enfield, Bren and Vickers chambers.

Let's face it, "reloading in the field" is not generally an approved military activity, especially on the two-way rifle range.

-

Thank You to Bruce_in_Oz For This Useful Post:

-

Advisory Panel

. . . Why do the cases lengthen? You can only lengthen at/to the detriment of something else surely? And surely, if they DO lengthen, then lengthening in this context is simply stretching. And in that case they'd lengthen uniformly along the total length - yes?

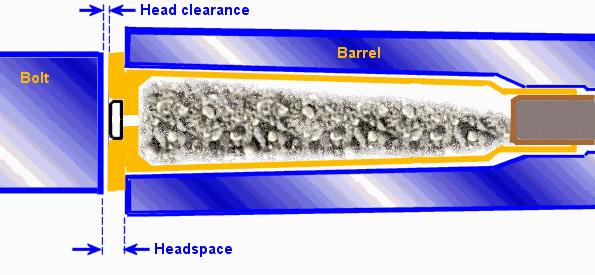

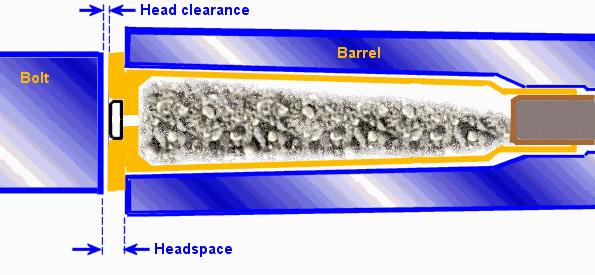

Cases lengthen on firing when some degree of axial play exists between the bolt face and the rear surface of the cartridge base.

1. The firing pin shoves the case forward, rim against the breech.

2. The primer detonates. If it's not heavily crimped in place, it backs out, shoving the bolt and barrel as far apart as it can.

3. The thin, forward part of the case expands to fill and grip the chamber while the bullet moves out of the case and down the barrel.

4. The solid case head can't expand and grip the chamber, so it moves rearward, re-seating the primer, stretching the case walls just forward of the head, and stopping when it hits the bolt face. (In rear-locking actions like the Lee, the bolt and receiver also compress/stretch to add a little more movement. The higher the pressure, the more they move.)

5. If (and only if) the amount of head movement exceeds the elastic limits of the case, the cartridge separates into two pieces. If it doesn't separate, it just get a little longer - and somewhat thinner at the point where it stretched. Image below shows this effect on the four US-made cases at right, all reloaded many times before being scrapped and sectioned.

In reloading, cases lengthen during full-length sizing. Cases expand radially to fit the chamber on firing - how much depends on relative case and chamber dimensions, as well as chamber pressure. In the resizing operation, the lubricated case is forced into a chamber-shaped die slightly smaller than a minimum chamber. Since the case head is supported by the sizing ram and the case body is squeezed radially, the metal displaced from case body diameter moves in the only direction open to it - forward into the neck where the case is not constrained by the die.

Both effects, localized stretch on firing and more general elongation during resizing, are cumulative during successive re-uses of the case. Elongation is addressed by trimming back the mouth of the case but stretching/thinning that occurs on firing is, for practical purposes, irreversible and eventually results in head separation unless the reloader monitors case condition carefully and discards those near fracturing.

The whole business can mostly be avoided by sizing only the necks of fired cases, producing reloaded ammunition with zero-end play in the chamber where previously fired and that hasn't been significantly elongated by full-length resizing.

Last edited by Parashooter; 09-08-2013 at 07:15 PM.

-

The Following 5 Members Say Thank You to Parashooter For This Useful Post:

-

Legacy Member

303 i have some brass like that very good quality (IMI) headstamp. I have had head separation on the second fireng of the case the metal was very poor quality brass. I only use neck collect dies. I also form 303/243 cases from either new 303 or already formed 303/270 or 303/25 and i can tell you some manufactureres use very poor quality brass in the first case. Without annealing i can get 7 reloads before neck / shoulder splits appear on good quality brass.

-

-

FREE MEMBER

NO Posting or PM's Allowed

Great write up and illustrations, Parashooter

Those sectioned cases don't show any visible sign of 'dough nut' formation.

-

FREE MEMBER

NO Posting or PM's Allowed

To All Who Have Responded:

Thank you for the informative input. I am learning a great deal about cartridges and reloading.

This rifle is one I bought out of nostalgia. About 50-60 years ago, many were the times I drilled with a Lee Enfield as a Cadet. Interestingly, I can still remember how to Slope Arms and Present Arms. I thought I might use it in Service Competition Target Matches.

The rifle is marked as FTR 1949. A .303 round placed nose first into the muzzle displays about 1/16" of bullet copper. A round placed in the chamber without stroking the bolt displays the all of the cartridge rim sides when pushed by hand forward. The bolt head shows a "0" marking.

I checked the rounds that came with the rifle. There were 14 R P 30.06 Sprg round, copper jacketed and showing nose lead. I fired 5 which appeared earlier in the post. The cartridges with splits in the neck are dated 1928, 1929 and 1930. Two have flattened primers. There are 7 other rounds with similar dates. I will not be loading them ever. They fired OK, and the bolt action was normal, not hard extraction.

Will seek some Privi, but having a hard time locating .303 British . Any suggestions folks?

. Any suggestions folks?

Thanks again for the great response. Ray

-

FREE MEMBER

NO Posting or PM's Allowed

I guess on line?

I dont now where to shop in the US,

303 British | Rifle Ammo | Ammo

Comes in FMJ 174gr or sp 150gr or 180gr, even others....

I suspect the wolf might be privy as well....

I have some 150gr coming....cant seem to get 180gr.....might try pulling a few and putting in a fmj as I cant get fmjs off the shelf in NZ .

.

---------- Post added at 04:13 PM ---------- Previous post was at 04:10 PM ----------

can you tell us what the full writing is on the left hand side of the receiver please?

PM

PM