-

Just a quick word on parashooters coments/ testing , First thing, i do hope there is no one in cose proximity when conducting these tests, Dont get me wrong i admire people who go out of their way to answer the question "why" and experiment, if people didnt we would still be rubbing sticks together to light a fire. But i wouldnt be doing this in an enfield,

Getting back to the subject i am studying at present, HND level maths and applied mechanics, i must admit i am c**p at these subjects but with worked examples am not too bad, looking at the calcs regarding

"the force on the web face minus the force used to strech the body, is the force that reaches the bolt face"

have been looking for a formula regarding the above, and using the one quoted, i dont think will give the required result, as far as i remember the formula is a bit long winded, and i dont know if it takes (youngs modulus of elasticity) into consideration as the elasticity of cartridge brass is 16,000,000 psi, which is about half of steel, other thing is Tensile strength is used and not yeild strength.

On a lighter note and a bit off the subject a lot of lads in my club have been stoking there .308 rounds up and always striving for accuracy etc, plus with the cost of the rifles (not enfields) and the glass approx £3500 +, it made me laugh while reading "Accurizing& shooting Lee Enfields By Brian Labudda and Ian Skennerton , page 5 last paragraph, regarding a Corporal Cox, on a L42A1 sniper course during the 1970,s who grouped shots into a headsized target @ 1000 metres, Anyone have any surplus 1970,s ammo ? and a L42A1 for sale.

, page 5 last paragraph, regarding a Corporal Cox, on a L42A1 sniper course during the 1970,s who grouped shots into a headsized target @ 1000 metres, Anyone have any surplus 1970,s ammo ? and a L42A1 for sale.

-

-

07-06-2009 08:26 AM

# ADS

Friends and Sponsors

-

Banned

page 5 last paragraph, regarding a Corporal Cox, on a L42A1 sniper course during the 1970,s who grouped shots into a headsized target @ 1000 metres, Anyone have any surplus 1970,s ammo ? and a L42A1 for sale.

One of the old books on target shooting I found recently actually commented on the effect of Luck on scoring.

I'm a believer in mind over matter, I've seen old timers fire a corroded old relic with far greater accuracy than the rifle could show in a machine rest.

I believe that in rare cases a great shot influences the path of the bullet after it leaves the barrel, very slightly of course, with his mind.

I have a fair amount of experiance with archery, and follow through is a necessity there. I think it carries over well to any form of projectile weaponry.

-

Legacy Member

>>>Getting back to the subject i am studying at present, HND level maths and applied mechanics, i must admit i am c**p at these subjects but with worked examples am not too bad, looking at the calcs regarding

"the force on the web face minus the force used to strech the body, is the force that reaches the bolt face"

have been looking for a formula regarding the above, and using the one quoted, i dont think will give the required result, as far as i remember the formula is a bit long winded, and i dont know if it takes (youngs modulus of elasticity) into consideration as the elasticity of cartridge brass is 16,000,000 psi, which is about half of steel, other thing is Tensile strength is used and not yeild strength.<<<

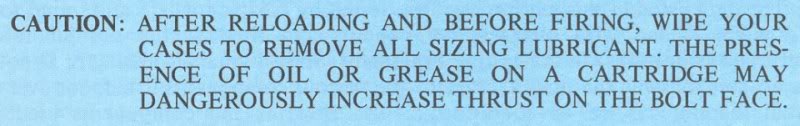

With a lubricated case, the case may be stretch very little or not at all. In such an example the head of the case may transmit the full load to the bolt face and the rest of the case just slips in the chamber.

If the case is not lubricated there are several possible scenarios and they have to do with the fit of the case in the chamber and the strength of the action. You can either analyze all cases, the best case or the worst case.

Generally you are interested in the worst case.

The rudimentary analysis that I have performed used Hooke's law and requires no knowledge of advanced mathematics. For the analysis of an odd shaped rear locking action the most time consuming part of the analysis is the measurement of the action and calculation of the cross sections under load.

-

-

FREE MEMBER

NO Posting or PM's Allowed

I find it interesting that Parashooter is getting so many reloads out of a Lee Enfield.

Rear locking bolts flex a lot more than front locking actions. Stuart Ottesen, in his book “The Bolt Action” says that the M788 rear locking bolt flexes .001” per 1,000 lb back thrust, which is more than five times the Model 700. Which is a front locking bolt.

Given so much flex in the system I am surprised any one is getting so many reloads regardless of whether the case is lubricated or not.

I got sprung bolts in my L39 with loads that chronographed 2400 fps with a 174 FMJBT. It surprised me as that is a very mild load in a front locking mechanism. So I can understand all the warnings not to have oil or grease in a Lee Enfield. Might break the bolt.

I have been shooting lubricated cases in my Garands and M1a’s close almost twenty years. These are front locking actions, very stiff compared to a Lee Enfield. I got the idea from a Distinguished HM gunsmith who shot the M1a. I will spare him the harassment so I won’t name him. He never cleaned his cases. He picked them up, rolled them in a towel saturated with RCBS water soluble case lube, sized them, primed them, loaded them, and he would take an entire set of cases a whole shooting season. He won every medal you can get as a Highpower shooter.

Heck, I earned my Distinguished and won a regional gold with lubricated cases in my M1a. I am on my third barrel with this M1a, and shot one with lubricated cases across the course on the 14th. Shot a 198-09 200 yard Sitting RF, and 191.04 300 yard prone RF. It was raining the whole day, it was cold, and as a group we quit before we went to the 600 yard line.

I compensated with an all you can eat fried chicken dinner.

I don’t like leaving greasy sizing lube on my cases. The stuff will pick up dirt. So I rub Johnson paste wax on my cases. Buff the ones to be used in rapid fire. I took one set 22 or 24 reloads. Never had a case head separation. Cases that had cracked necks or body splits, I sectioned. No evidence of case head separation.

I have shot plenty of cases with RCBS on the outside. And the absolute worst lube I used was stick wax. Awful stuff. Tenuous and sticky. The stuff is supposed to stick to the teeth of saw blades and lubricate the cut. I dropped some of that in a plastic bag with most of my Cavim cases. Shook the whole lot. I fired close to 1000 rounds of 308 cases coated with that gook in my FAL. I was able to open the gas valve open a significant amount as the cases were not sticking in the chamber and the action did not need as much gas to function the mechanism.

I don’t recommend stick wax as the stuff can’t be washed off in soapy water and it leaves a thick coating. It gets on your fingers, your rifle, and it is stays on.

Some automatic weapons were designed to be used with lubricated cases.

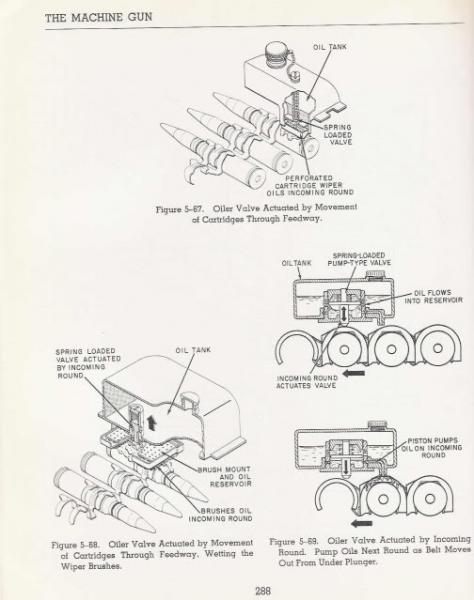

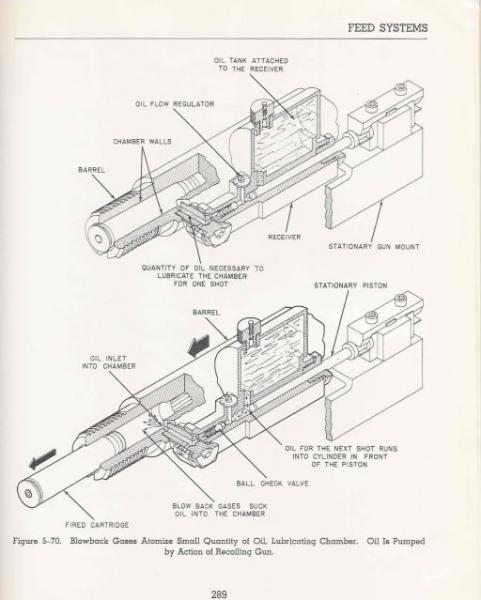

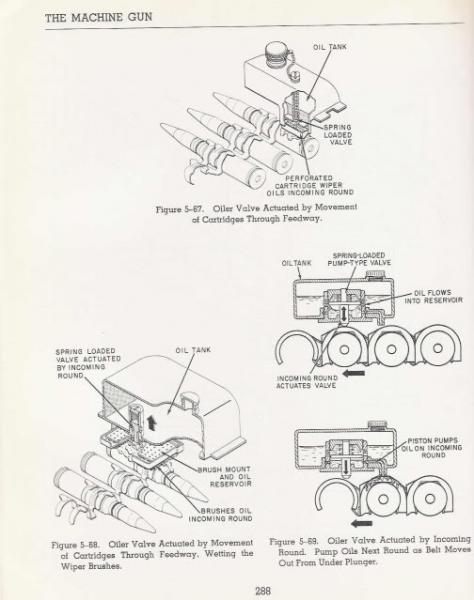

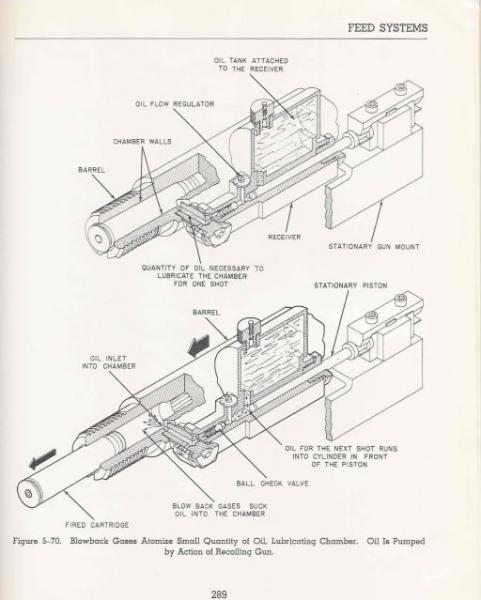

LTC Chin documented the essentials of machine gun design in his Vol IV of the Machine Gun. Most people are just interested in pretty pictures of machine guns, which are in Vol I-III, but for those interested in design, Vol IV is the treasure.

The appendixes have schematic illustrations of representative mechanisms. All sorts of locking mechanism, feed mechanisms, and these oiling systems. These two pages present to designers already developed mechanisms on lubricating cartridges for machine guns.

In the text of the book, designers are made aware of the limitations of lubricants, and that lubricants were essentially designed out of the systems of modern machine guns. However, if the designer is not able to reduce the breech friction for other means, these images were there to help the designer to escape from the corner he painted himself into.

So, the use of lubricated cases have a sound technical basis. That is, to reduce breech friction.

These images are taken from "The Machine Gun", Vol IV, author LTC Chinn, published Bureau of US Navy Ordnance.

I highly recommend everyone seek to acquire Vol IV for a better understanding of firearms design. It took me years (pre internet) and I only had to pay $150.00 for mine. And that was 15 years ago.

You can buy one from Amazon for $349.00! http://www.amazon.com/gp/offer-listi...0897817&sr=1-5

-

Banned

-

Originally Posted by

slamfire1

I find it interesting that Parashooter is getting so many reloads out of a Lee Enfield.

Rear locking bolts flex a lot more than front locking actions. Stuart Ottesen, in his book “The Bolt Action” says that the M788 rear locking bolt flexes .001” per 1,000 lb back thrust, which is more than five times the Model 700. Which is a front locking bolt.

Given so much flex in the system I am surprised any one is getting so many reloads regardless of whether the case is lubricated or not.

I got sprung bolts in my L39 with loads that chronographed 2400 fps with a 174 FMJBT. It surprised me as that is a very mild load in a front locking mechanism. So I can understand all the warnings not to have oil or grease in a Lee Enfield. Might break the bolt.

1. First of all, what is a "sprung bolt"?

2. This is a bit longish, but if you're going to quote Otteson, let's put into a bit more context shall we? So:

"More basic is the problem of simple linear deflection...there was no practical way to achieve a rigidity equal to that of a front-locked action.

"The 788 bolt actually compresses more than the receiver stretches, and both would have to be made unrealistically massive to compensate. This is not a function of the strength or grade of steel, since within their elastic range, all have virtually the same modulus or stretch characteristic. A high-strength heat-treated steel simply remains elastic longer. Few useful metals exceed steel's 30,000,000 lb/sq. in. modulus.

"Stretch of the 788 during firing can be roughly computed-about .001 in. per 1,000 lb. back thrust. Actual tensile measurents made at Remington's Ilion laboratory confirm this figure, giving approximately the same results, just slightly higher. This stretch may seem negligble, yet it far exceeds the give in a front-locked action. It is more than five times that of the Model 700. What are the practical effects? None, insofar as the strength, safety, and accuracy of the 788 is concerned. It can affect reloading ammunition. While still not required after each firing as with some non-bolt guns, occasional full-length resizing may be necessary in certain calibers to maintain smooth operation. Remington factory tests indicate that .22/250 cartridge cases, for example, required resizing each five to ten firings."

Quoted from:

The Bolt Action (A Design Analysis)

by Stuart Otteson

Copyright 1976

Winchester Press (Publishers)

ISBN 0-87691-175-0

(please excuse any typos, I'm a slow, unskilled typist and have limited time to get all this down!)

Bold faced area was added by me.

In the appendix under the section of "Bolt Back Thrust", he assigns very little to no useful load carrying capacity for the cartridge case walls, but he also assigns the older CUP values of chamber pressure. At any rate, given a maximum I.D. of a 30-06/308 Win case of 0.400" Leads to a back thrust of 6300 lb. (In a case head separation event this value would be 8,800 lbs. at 50,000 psi. given an O.D. of 0.473") You can convert these values to 60,000 psi. by dividing by 5 and then multiplying by 6.

Given an O.D. of 0.450" , wall thickness of 0.036" and ultimate strength of 75,000 psi., a case could theoretically absorb up to 3525 lb. of the back thrust (303 British , 3675 lbs. max. 308 Win.). But only w/ zero slip and wall thinning. Since cases DO thin at the web, this value is rather less. SWAG of 1500-2000 lbs.(?)

, 3675 lbs. max. 308 Win.). But only w/ zero slip and wall thinning. Since cases DO thin at the web, this value is rather less. SWAG of 1500-2000 lbs.(?)

BTW, the "weak" Rifle 2A1 in 7.62x51 has a chrome lined chamber, generally, if you think frictional modifiers are important. I must not as I've fired all sorts of random ammo through mine w/ no ill effects -one has over 2000 rds through it at latest tally, much of it rapid fire.

What we need are steel yield strengths, and at least minimum cross sectional areas, plus ACTUAL bolt lug bearing and shear areas calculated for No.1 and No.4 actions, both w/ and w/o mag cutoff slot. and cutoff boss. (Just need to actually measure the "shiny" part of the lug surfaces to get working bearing areas.

3. AND! No need to buy Lt. Colonel Chinn's books (all Five volumes!) when its available for the reading right here on our lovely little web site:

The Machine Gun (by George M. Chinn) - Military Surplus Collectors Forums

Last edited by jmoore; 03-24-2010 at 05:12 AM.

-

Thank You to jmoore For This Useful Post:

-

Just thinking and working, (a hazard w/ long running jobs), it occurs to me that IF you think these rifles are borderline dangerous, the two factors of case wall thickness and the brass ultimate strength are of far greater importance than a 20% difference in chamber pressure...Or,possibly, dare I say it, lubrication?

Both are subject to variations of which the average shooter will never be aware.

-

Thank You to jmoore For This Useful Post:

-

FREE MEMBER

NO Posting or PM's Allowed

1. First of all, what is a "sprung bolt"?

A term I made up. My L39 bolt lift was stiff. The bolt evidentially was under compression after the cartridge was fired.

What we need are steel yield strengths, and at least minimum cross sectional areas, plus ACTUAL bolt lug bearing and shear areas calculated for No.1 and No.4 actions, both w/ and w/o mag cutoff slot. and cutoff boss. (Just need to actually measure the "shiny" part of the lug surfaces to get working bearing areas.

Agreed, if you are going to do a proper mechanical stress analysis of the Lee Enfield. Unfortunately the No 4 is a legacy design product improved from an 1880’s ancestor. Last one were built, what in the 50’s?

What steels were the No 4’s made from? Were they just plain carbon steels, or were they alloys?

I have lubricated cases in my No 4 Mark II with cast bullet loads. But frankly, as springy as a Lee Enfield action is, I am not interested in using lubricated cases with full power loads.

I use lubricated cases to extend my case life. Good brass is expensive, and I want to be able to reuse good brass for as long as I can. I use most of my lubricated cases in Garands and M1a’s. These rifles are hard on brass. I have shot thousands of 30-06 rounds in matches, and ten of thousands of 308 rounds in matches.

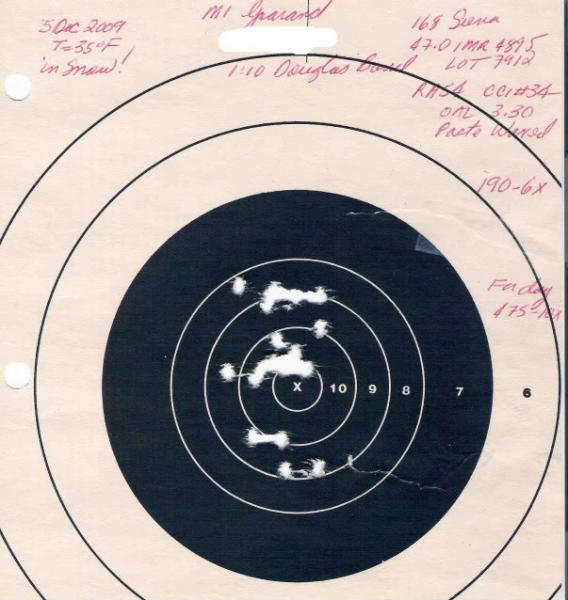

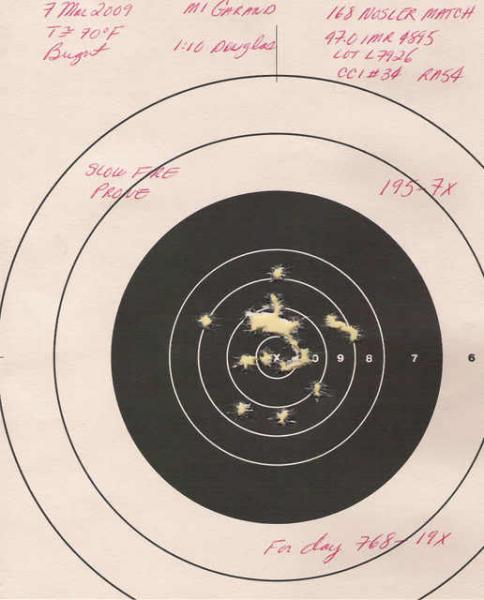

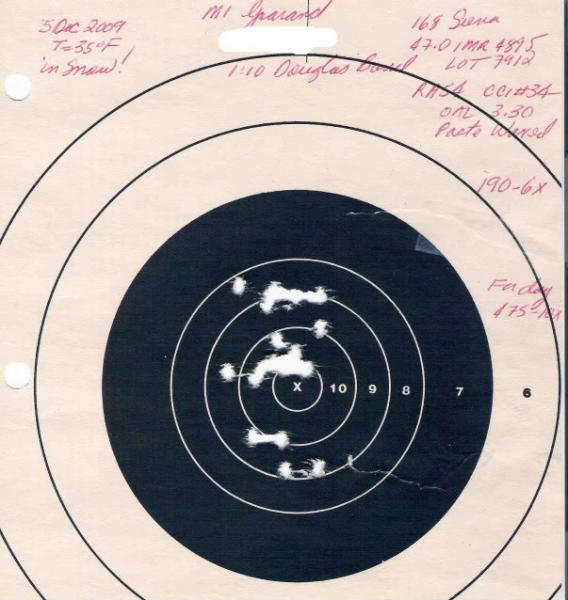

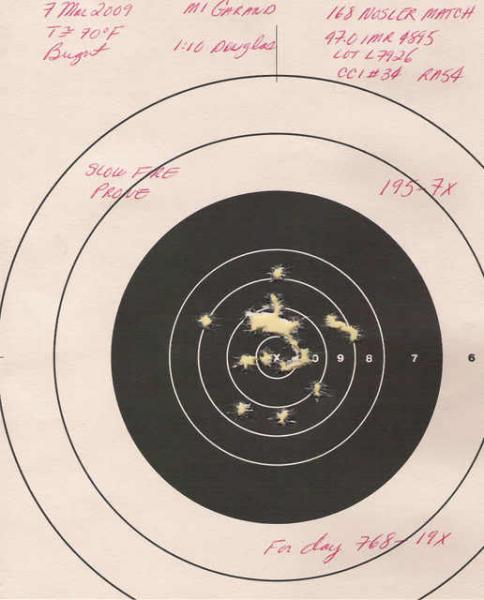

I do not shoot magnum rounds nor are my loads “hot”. For the 30-06 I shoot a 168 SMK with 47.0 grs IMR 4895. This pushes a 168 match bullet just at 2700 fps in a 26” match barrel, just at 2650 fps in the Garand . I have faith that this load does not exceed 50,000 psia, is probably closer to 45,000 psia. In the 308 MIA I shoot a 168 SMK 41.0 to 41.5 grains IMR 4895. Velocity is between 2550 fps and 2625 fps. Pressures are probable close to 50,000 psia.

. I have faith that this load does not exceed 50,000 psia, is probably closer to 45,000 psia. In the 308 MIA I shoot a 168 SMK 41.0 to 41.5 grains IMR 4895. Velocity is between 2550 fps and 2625 fps. Pressures are probable close to 50,000 psia.

I don’t shoot the Garand but one or two times per year, my Club has an annual “Garand Match”, so I don’t shoot it was well as my other rifles, but lubricated cases at 100 yards, and 600 yards shoot very well. These targets were with my Garand at my local 100 yard Highpower match. These are 20 rounds prone, slow fire.

Within my limits and my loads I am not having any problems. My case life is exceptional in these actions which are known to have short case life. The typical advice is five reloads and toss the case. I have taken cases 22 or 24 reloads.

I highly recommend visiting this site and seeing a dynamic analysis of chamber finish/case fricition. Rifle Chamber Finish & Friction Effects on Bolt Load and Case Head Thinning Calculations done with LS-DYNA What I want to point out is that as case friction is reduced, case stretch is reduced. If this is true, it may mean that that cases are less likely to rupture, either through a brass flaw, or through repeated firing, if the cases are lubricated.

But this would only be in stiff front locking actions. In an antique rear locker, such as a Lee Enfield, the whole action and bolt will stretch so much that cases could break. What can you say about reloading for an action that is so flexible that even the British NRA recommends not to shoot these rifles in the rain?

NRA recommends not to shoot these rifles in the rain?

I would say, load them light. Real light.

-

FREE MEMBER

NO Posting or PM's Allowed

Except for long term storage, who puts grease in their rifle chamber/bore? I was taught at an early age, I am now 66, to always check the bore of the gun you are going to shoot for dirt/obstructions. If there is anything that looks suspecious, clean it.

I love to shoot my Enfields, all of them.

I may shoot lubed cases from my reloading. I use a wax based case lube that I just wipe off with a cloth after sizing. There may be lube in my chamber/bore. The lube I use is LPS2 which is a milspec lube/rust preventative which dries after application. I have been using this for 20 years or so.

If you think that a sticking bolt is caused by a mechanical problem with a rifle, you have not shot a Mosin Nagant. With some brands of ammo, the green steel cased stuff, you might need a mallet to open the bolt. The lacquer on the cases melts and turns to glue. A rough chamber may be the reason your bolt is hard to open as the case is stuck to the rough surface of the chamber.

When I reload, I do so for accuracy, not velocity. The only exception is my Win 243 varmit rifle which likes fast bullets. My reloads never reach the max loads given in the manuals.

All this theroy makes my head hurt but it is interesting reading....chris3

-

Banned

In 1974 I sent a .270 Remington 760 Gamemaster to a Remington repair facility for warranty work. I had bought a bad batch of Remington primers that were recalled and these primers ruptured and scored-etched the bolt face with high pressure gas.

After the Remington repair facility received my .270 I received a call from the repair facility shop manager. I was accused of shooting extremely high pressure reloads in my Remington pump and this had damaged my rifle. I told the manager my rifle was sent back for repairs due to defective primers sold by Remington and the manager said he knew this but I also had damaged the rifle from hot loads. I told the manager I was loading 52 to 53 grains of IMR4350 and this was will below any maximum load.

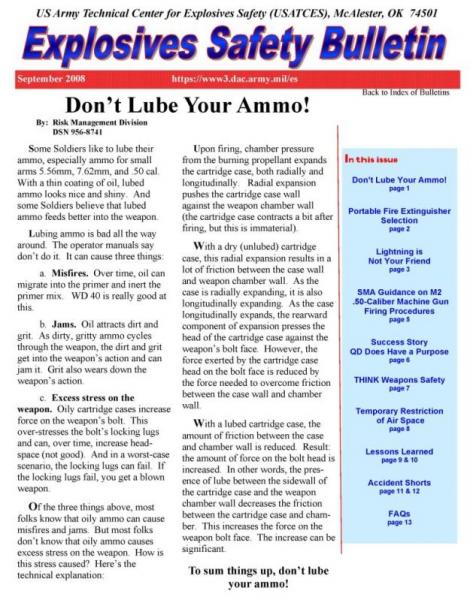

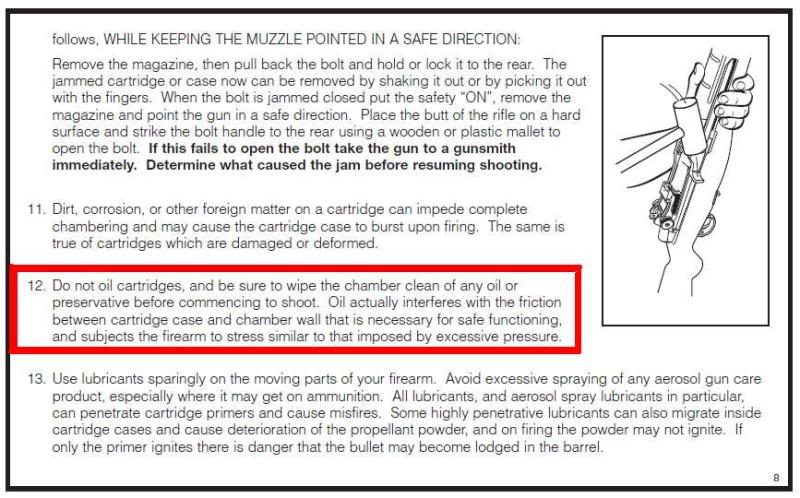

Then came my surprise, the manager then asked me if I was lubing my case when fire forming them and I answered “yes”. There was a long sighing exasperated pause at the manager’s end of the phone and then he said in no uncertain terms to NEVER lubricate another case ever again because it places to much force on the bolt and receiver.

I stopped lubing or oiling cases in 1974 and I highly recommend that no one else does it either, there is a reason why you are told not to do it by the fire arms manufactures, the ammunition manufactures and the reloading companies.

The people who recommend oiling case do NOT have the sophisticated laboratory testing equipment these large companies have and lubing cases started back when Christ was a Corporal in the black powder age.

The effects of bolt thrust and lubing cases are accumulative and add up over time and can damage any rifle. Below is from the American H.P. White testing laboratories.

1.4 Failure of a gun assembly from internal pressure may be from either

of two (2) failure mechanisms.

1.4.1 The general perception is that those failures are the result

of a single exposure to a CATASTROPHIC PRESSURE level. This

may be an over simplification in that the strength of the

assembly may have been degraded by previous repeated exposures

to excessive, but lesser, levels of pressure whose cumulative

effect is to reduce the ultimate strength of the assembly.

1.4.2 Repeated exposure to pressures which exceed the elastic limit

of a material will continually reduce the ultimate strength of

the material until the ultimate strength is exceeded by a

relatively low pressure level causing fatigue failure.

http://www.hpwhite.com/uploads/file/101-00.pdf

HP White :: Home

, page 5 last paragraph, regarding a Corporal Cox, on a L42A1 sniper course during the 1970,s who grouped shots into a headsized target @ 1000 metres, Anyone have any surplus 1970,s ammo ? and a L42A1 for sale.

PM

PM