-

FREE MEMBER

NO Posting or PM's Allowed

303 British Load data for 150gr speer sp flat base !

What would be the starting grain for loading 303 with Speer 150gr sp. powder to use is imr4895.

http://data.hodgdon.com/cartridge_load.asp the link doesn't show a test data. for IMR4895.

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

03-26-2012 08:42 PM

# ADS

Friends and Sponsors

-

FREE MEMBER

NO Posting or PM's Allowed

I dont know about speer or imr4895 but I have had good luck with Hornady 150 gr flat base soft points and reloader 15 powder. If you dont get the results you are hoping for, yu might try it out.

mdrim13

-

They have a maximum load, but no starting load... Generally that means reduced loads were unsatisfactory. Probably pressure swings are too great as the powder burn is not uniform at the lower pressures/loading densities. I'd try another powder in this case!

-

-

FREE MEMBER

NO Posting or PM's Allowed

I looked at the Speer Manuel and they seem to like imr4895 with 40grain 150sp flat base. Lyman on the other hand doesn't show the test data for imr4895 instead they have H4895 starting is 37gr. H4895 is a higher burning rate than the imr4895. I always reduce the starting load data by 5% and move up to find the sweet spot. For safety concerns/ something happens I am always go 5% lower the suggested starting load.

-

FREE MEMBER

NO Posting or PM's Allowed

My Speer Manual #10 shows Speer 150 Gr. SP using IMR 4895 as follows: 41gr-MV 2663; 43gr-MV 2779 and max load 45gr-MV 2907. I have used this load at 43gr. it is OK but prefer to use Hornady Bullets with 0.312" dia.

-

FREE MEMBER

NO Posting or PM's Allowed

Ranch relultsEnfield No4 mKI 303

Just got back today. used Speer 150gr sp/ imr4895 40grpowder result were ok at 100Y

total 19 shot all in 4 inch spread. Only onequestion. I am getting powder residue from nick up! More than normal. Iam not crimping the cases. only using one shot at time bench shots, loading one at a time.

Attachment 32909Attachment 32910Attachment 32911

-

-

Thank You to Parashooter For This Useful Post:

-

Legacy Member

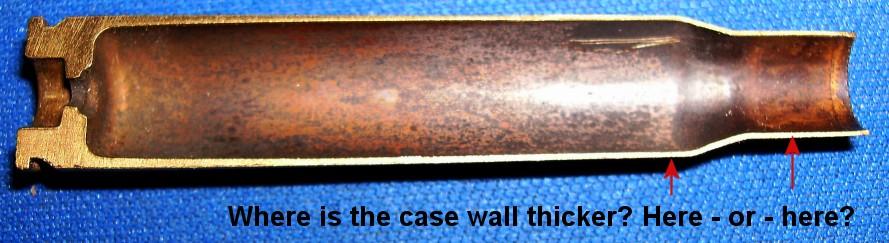

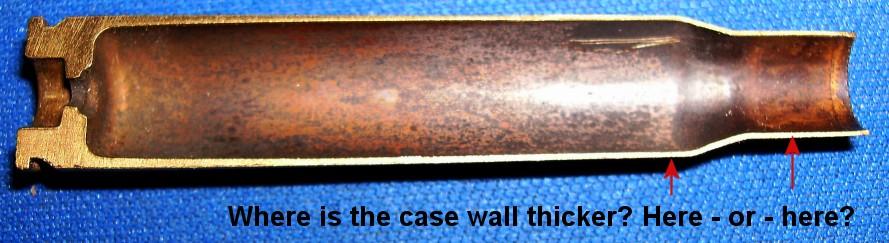

Interesting hydraulic effect on the thinner necks, Ray

-

-

Advisory Panel

Originally Posted by

rayg

Interesting hydraulic effect on the thinner necks, Ray

Looks like some further explanation is needed. In fact, the brass is normally thicker at the neck than at the shoulder and the forepart of the body. This is because the case is drawn as a cylinder with gradually tapered walls. When the final forming is applied, the reduced diameter of the neck results in the brass there becoming thicker than before neckdown, while the area just aft of the neck remains nearer the original thickness.

-

The Following 2 Members Say Thank You to Parashooter For This Useful Post:

-

FREE MEMBER

NO Posting or PM's Allowed

Parashooter

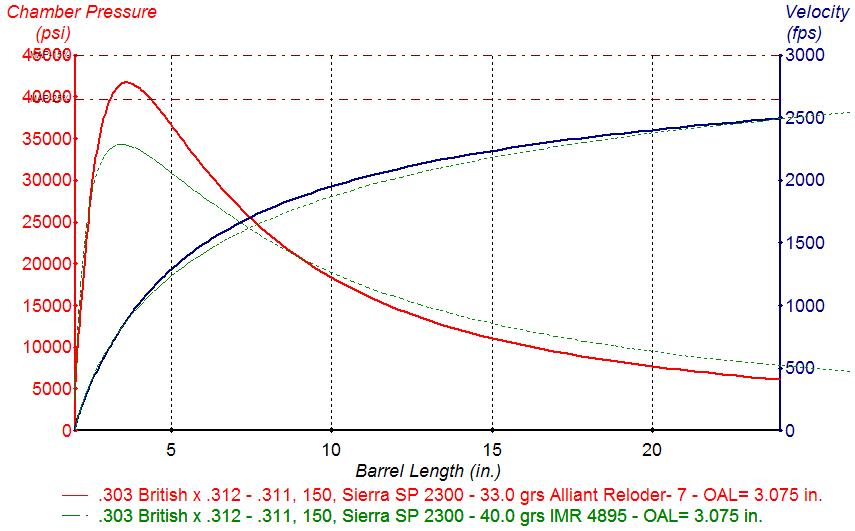

You're seeing soot on the necks because the bullet base is leaving the case before the neck has expanded to seal against the chamber. This is to be expected with a short bullet and a ~34000 psi load, which is what you're shooting.

If the soot bothers you, there are several approaches that may eliminate or reduce it -

Heavier/longer bullets

More powder

Faster powder

Seat bullets deeper

Anneal necks

Size necks only to depth bullet is seated

Thanks parashooter great feedback Wow! To maximize my POI, i seated close to the rifling, and with 150gr i will get some soot like you said. i don't mind its good. check out my thread on the Enfiled side of this forum.

Register To Reply

Register To Reply