-

FREE MEMBER

NO Posting or PM's Allowed

they have a gas check and are prelubed, i got a hold of some imr 4895 for it to try.just need a starting point on how much to charge the case with.I did roll crimp for the 30-30 i originaly bought them for ,shot well, but were talking bolt action mil-surp now . I will continue my research quest or end up trying to sell them just seems they would work in a mosin but i am no lead bullet expert.Hate to have to take a loss on the bullets but if it wont work it wont work right?thanx guys.

-

11-10-2013 11:57 AM

# ADS

Friends and Sponsors

-

FREE MEMBER

NO Posting or PM's Allowed

As you have said the bore slugged .308" so the .310" dia. bullet will work fine,it will probably shoot a larger dia. cast bullet as long as it will chamber. In general you can measure the inside case neck dia. of a once fired case and subtract .001" and that dia. bullet should work fine but your .310" should do well.

As for powder you have quiet a few options. My go to powder for 170 gr. cast lead gas check bullets in my Mosin is 16.0 grs. of Alliant 2400 My second option is 13.0 grs. of Alliant Red Dot no fillers needed in either load and they simply shoot great an those powders burn very clean in the longer rifle barrels. I throw both these charges with my RCBS Lil Dandy powder dumper,I also used a med. roll crimp in the provided crimp groove on the bullet.

If you don't have 2400 or Red Dot Ed Harris says the following

Sixteen Grains of #2400 is the Universal Load

The same 16 grain charge of #2400 is universal for all calibers as a starting load. It is mild and accurate in any larger military case from a 30-40

Krag

or .303

British

up through a 30-06 or 7.9x57, with standard weight bullets of suitable diameter for the caliber. This is my recommendation for anybody trying cast bullets loads for the first time in a military rifle without prior load development. I say this because #2400 is not "position sensitive", requires no fiber fillers to ensure uniform ignition, and actually groups better when you stripper-clip load the rifle and bang them off, rather than tipping the muzzle up to position the powder charge.

Similar ballistics can be obtained with other powders in any case from 7.62x39 to 30-06 size. If you don't have Hercules #2400, you can freely substitute 17 grains of IMR or H4227, 18 grains of 4198, 21 grains of Reloder 7, 24 grains of IMR 3031, or 25.5 grains of 4895 for comparable results.

However, these other powders may give some vertical stringing in cases larger than the 7.62x39 unless the charge is positioned against the primer by tipping the muzzle up before firing. Hercules #2400 does not require this precaution. Don't ask me why. Hercules #2400 usually gives tight clusters only within a narrow range of charge weights within a grain or so, and the "universal" 16 grain load is almost always the best. Believe me, we have spent a lot of time trying to improve on this, and you can take our word for it.

Other powders that work well with cast loads not mentioned above are Unique,SR-4759,Accurate 5744.

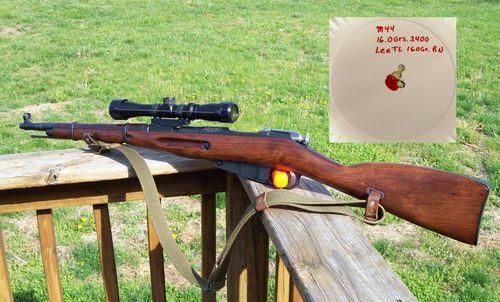

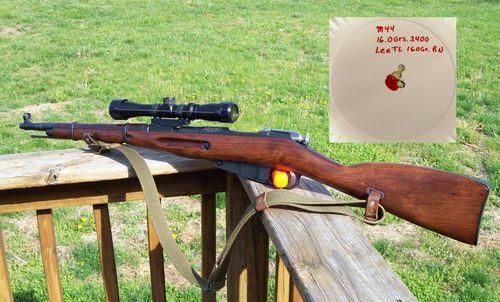

I shoot the Lee 160 gr. ends up being 170 with lube a gas check applied in my Mosin I originally bought it to shoot in my SKS rifle but turns out they all had the same groove dia. so the Mosin get to use it to,I've even sized them down to .311" and it shoots great in my Sav. 99 in 300 Sav.

5 shot test group using the 16.0 gr. Universal Load

-

FREE MEMBER

NO Posting or PM's Allowed

dude , you just gave me all i needed to start , yes its a perfect .308 dia in mosin sniper model, I was pretty sure they could be used as well as i have used oversized cast bullets in my blackhawks with mo problems as long as you stay within a few thousnads of bores size.. i have a lb of 4198 i could use for testing loads and if i can find some 2400 ill grab it up ,i have damn near 500 of these bullets and thought same thing use in my mosin, .310 , are 30 cal , should easily work was my thinking thanx my freind , now at least i have a starting point.Thats an impressive grouping from an M44 ?Damn fine shooting with lead bullets. have you ever had leading probs in barrel after using the lead bullets?

-

FREE MEMBER

NO Posting or PM's Allowed

Have you ever had leading probs in barrel after using the lead bullets?

Not in any of my rifles I shoot cast lead plain base and gas check designs in them all an in some low velocity plinker loads where the gas check isn't needed I just leave it off completely. Those are mainly shot in the old Sav. 30-30 pump gun using 7.0 grs. of Red Dot. But I just recently picked up another mold that throws a Lee .314" tumble lube 90 gr. SWC drops at .315" with pure lead that I shoot sized to .314" in my Mosin and SKS and size it down to .311" for all my 30 cal. US rifles.3.0 to 3.5 grs. of Alliant Bullseye provides the power to get that little bullet just over 1K fps. darn accurate as well and shoots under 2" at 50 yds in all the rifle I use it in.

The only real leading issued I have is in a new Taurus 357 mag. revolver I bought a couple years ago the forcing cone is a little rough an likes to strip a little lead with plain base bullet but with a gas check design it's not a problem,the little bit of leading I do get is easily removed. It will work itself out after I put enough rds. through it and smooth that out.

Was just looking through some of my cast bullet load manuals and they have a Saeco 180 gr. #2 alloy cast bullet similar to the 170 gr. you have,the starting load in the Lyman Cast Bullet manual #4 using the 180 gr. bullet is 20.0 grs. of IMR-4198 @1600+ fps. you will most likely get that and a little better using the 170 and that's plenty of velocity for paper punching,small game or varmints or Med size deer.

The LazerCast bullet is way harder than #2 alloy and want expand but the flat nose portion of the bullet will do the work and create a decent wound channel.

Last edited by SKS50; 11-14-2013 at 07:13 PM.

-

FREE MEMBER

NO Posting or PM's Allowed

Originally Posted by

SKS50

Not in any of my rifles I shoot cast lead plain base and gas check designs in them all an in some low velocity plinker loads where the gas check isn't needed I just leave it off completely. Those are mainly shot in the old Sav. 30-30 pump gun using 7.0 grs. of Red Dot. But I just recently picked up another mold that throws a Lee .314" tumble lube 90 gr. SWC drops at .315" with pure lead that I shoot sized to .314" in my Mosin and SKS and size it down to .311" for all my 30 cal. US rifles.3.0 to 3.5 grs. of Alliant Bullseye provides the power to get that little bullet just over 1K fps. darn accurate as well and shoots under 2" at 50 yds in all the rifle I use it in.

The only real leading issued I have is in a new Taurus 357 mag. revolver I bought a couple years ago the forcing cone is a little rough an likes to strip a little lead with plain base bullet but with a gas check design it's not a problem,the little bit of leading I do get is easily removed. It will work itself out after I put enough rds. through it and smooth that out.

Was just looking through some of my cast bullet load manuals and they have a Saeco 180 gr. #2 alloy cast bullet similar to the 170 gr. you have,the starting load in the Lyman Cast Bullet manual #4 using the 180 gr. bullet is 20.0 grs. of IMR-4198 @1600+ fps. you will most likely get that and a little better using the 170 and that's plenty of velocity for paper punching,small game or varmints or Med size deer.

The LazerCast bullet is way harder than #2 alloy and want expand but the flat nose portion of the bullet will do the work and create a decent wound channel.

Thnax for all the help my friend , at least i have a use for these .310 170 fp's that i have near 500 of , soon as the weather breaks i will deff try this 4196 i have and see if i can locate the other powders, powder in the Ohio valley area has gotten hard to come by, most times the day it hits shelves its all gone around here , does seem to be making a small comeback now in availaility , all the dems did with their stupid anti gun rhetoric is make it hard on us never broke law 1 in our life ,very difficult to even reload our own, took me 5 months to locate 5000 rifle primers and 2000 pistol, just ridiculous how they let these people determine prices and availability of ammo and reloading components along with the price gouging of weapons that were selling for 4 times what they were worth, they will not stop till they get their way , all who read this forum remember which dems or turncoat repubs were ,i have them written down, so next november , i can watch em all cry when we vote them all out of a job, the repubs may be greedy, but not once have they come after my rights and trampled on our 2nd amendent rights like these people in office have now.

Register To Reply

Register To Reply