-

Contributing Member

That is flawless work. I am definitely in the market for a bunch of these!

Will you be making nose caps as well? Both MkII military and target caps and MkIII military caps are needed badly. I would likely take several of each and probably a half dozen or so hoods at least.

As for bluing, radocy rust blue is nearly a perfect match for factory bluing. I can send pics if you'd like.

-

-

02-08-2015 11:23 AM

# ADS

Friends and Sponsors

-

Legacy Member

Originally Posted by

flying pig

That is flawless work. I am definitely in the market for a bunch of these!

Will you be making nose caps as well? Both MkII military and target caps and MkIII military caps are needed badly. I would likely take several of each and probably a half dozen or so hoods at least.

As for bluing, radocy rust blue is nearly a perfect match for factory bluing. I can send pics if you'd like.

Hi Flying Pig, am quite a fan of your work with Ross's also

Would definitely be interested to hear more about the radocy blueing, and if you've got pics that'd be a real bonus.

Am currently working away at the fabrication of a MkII nosecap and my experiences here will ultimately determine weather or not they can be feasibly made in any great quantity on the available machinery. I believe the main stumbling block will be my ability to machine the bayonet lug/piling hook component in a cost effective manner on manual machinery. There's multiple setups involved and as a dividing head is used to shape the radii it means each lug needs to be made singularly. I'd likely have to outsource that job to someone with a little 4-axis CNC mill. Things could get $$$, very quickly.

Anyway as per post #2 I've already machined the lug required for this 1x prototype nose cap, so will press ahead to complete it's fabrication then down the track when I'm at the stage of weighing up feasibility etc will get some quotes on CNC machining.

All currently hypothetical but if any @ all are eventually made for sale, they'd be based around sheet metal construction (i.e. MkII style) as this is where my comfort zone is - the single piece forged MkIII type would be too involved. This would cater for the any of the military MkII's, the MkII** (Heavy Barrel version), and the very early MkIII's (that used left over MkII caps).

Am finding quite a wide variance in internal dimensions of the different types of MkII nosecaps, which will make the design of forming tooling bit of a challenge.

As for the sight hoods I imagine most will want them supplied in a blued finish and with the appropriate screws, so my intention had been to offer them in kit form.

To date the lions share of the work has been directed toward nutting out the hoods manufacture, will now need to turn my attention to sourcing (and likely modifying) the little bolts and researching the blueing etc.

Am reluctant to put a time frame on how long this will likely take, but in the mean time will certainly keep you all updated & informed of progress via the forums.

Also a massive thanks goes out a few members on the rossrifle.com forums.

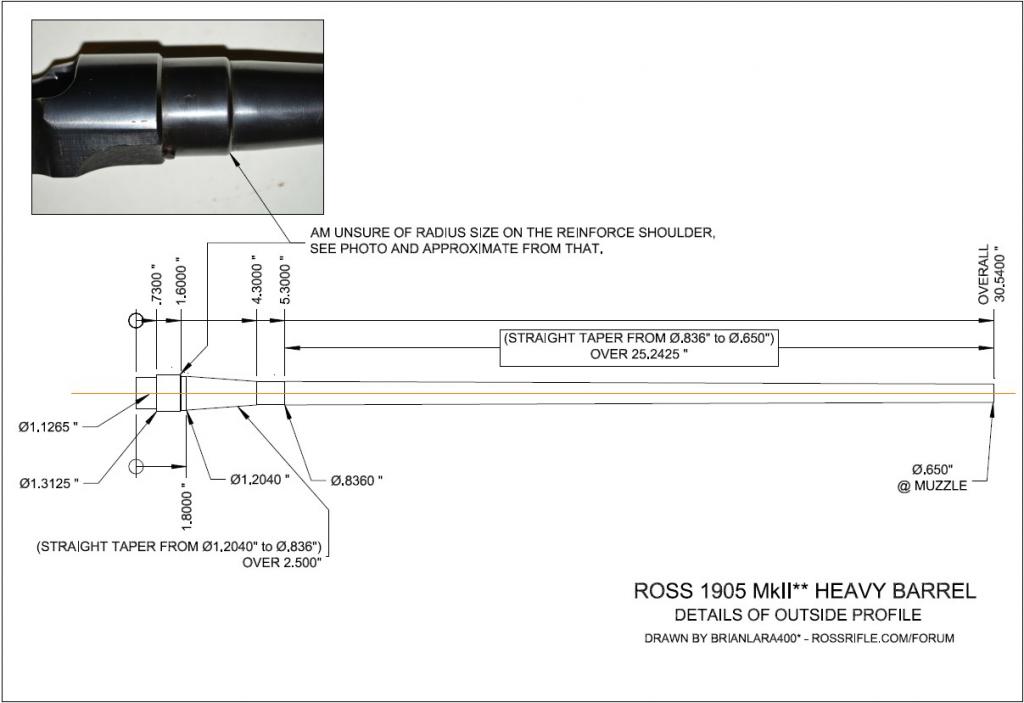

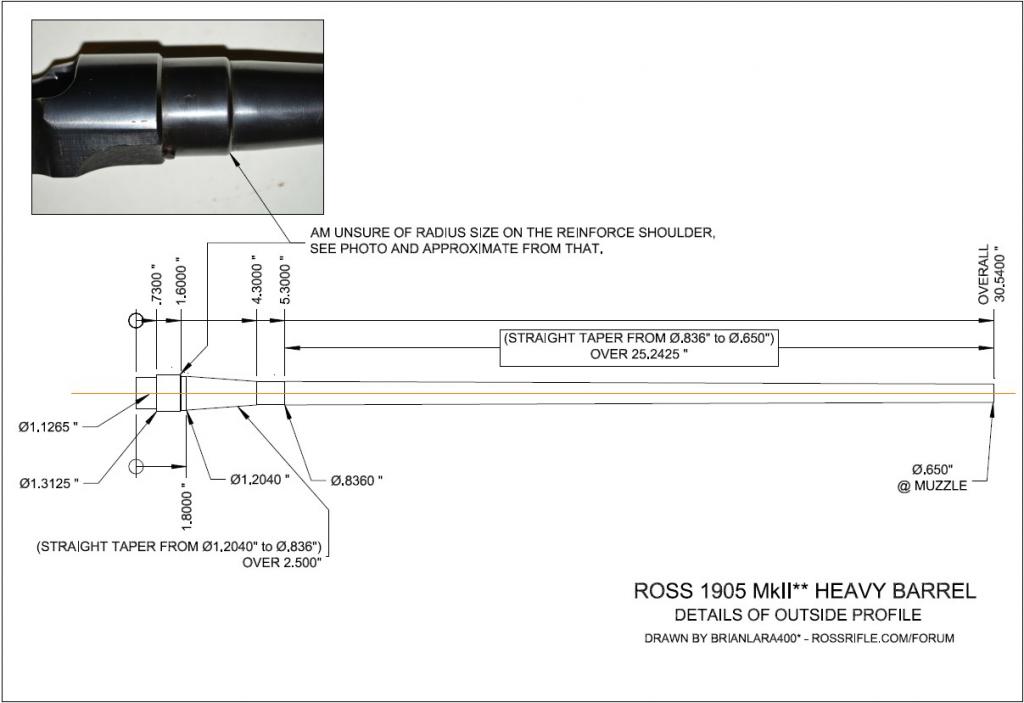

They were able to measure the contours of the heavy barrels on their MkII**'s for me, and here's the resulting drawing.

(I did add a little to the tennon length to match the other ross barrel drawings I've seen - far easier to remove material, than add it back on

(disclaimer the PDF formatting of my CAD program, is playing up quite a bit and leaving bits out?)

Last edited by BrianLara400*; 02-11-2015 at 03:07 AM.

-

PM

PM