-

Legacy Member

Originally Posted by

Joe H

Attachment 62625Attachment 62626

IIMO the use of brass or steel really is not the crux of Djandj’s problem. He currently has some brass Yugoslav 54r to try. If its 182 gr I’m not sure how it will work in a Bren. Has anybody used 182gr in a Bren? If he tries it without any problems does it really tell us it is a brass vs steel issue?

Djandj,

I guess your trip to the range answered my questions. Did you fix the headspace issue?? I wouldn't reload those brass cases unless you have a 54r die with a double shoulder

IMO the 182 gr 54r is a long range sniper load for a rifle. I don't know of anyone who has used it in a Bren. The only experience I have is the steel cased "light ball". You may be in uncharted territory .

.

You might try to mike the brass case at the locations shown to see if the bass is bulged.

Does the Gun work properly with a .303 barrel ?

IMO you haven't "traded problems" its the same problem.

Joe

Last edited by Joe H; 05-18-2015 at 07:42 AM.

-

-

05-18-2015 07:09 AM

# ADS

Friends and Sponsors

-

Legacy Member

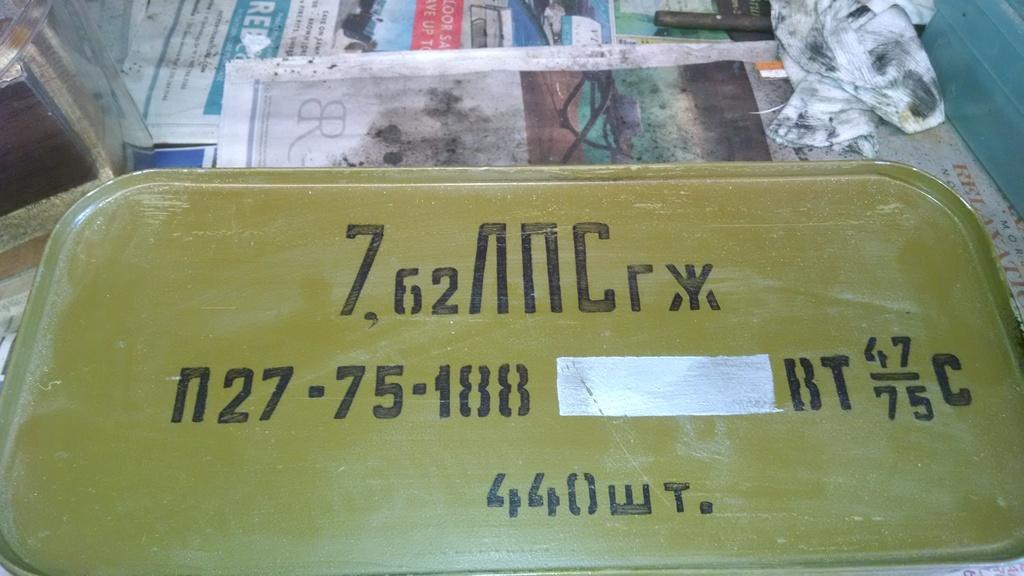

just pointing out that the steel he is using is heavy ball not the normal light ball that is normally used.

-

-

Advisory Panel

Why not just section several brass cases and find out what's happening inside for sure. No, I wouldn't reload that stuff. Perhaps a bit of chamber polishing will help? Couldn't hurt...

-

-

Legacy Member

Originally Posted by

Joe H

Djandj,

I guess your trip to the range answered my questions. Did you fix the headspace issue?? I wouldn't reload those brass cases unless you have a 54r die with a double shoulder

IMO the 182 gr 54r is a long range sniper load for a rifle. I don't know of anyone who has used it in a Bren. The only experience I have is the steel cased "light ball". You may be in uncharted territory

.

You might try to mike the brass case at the locations shown to see if the bass is bulged.

Does the Gun work properly with a .303 barrel ?

IMO you haven't "traded problems" its the same problem.

Joe

Thanks Joe. No I haven't touched the HS issue yet. No one seems to have the right sized shoulder (and I haven't found anyone willing to mill the .005 off it I need.). The question is "do I need it" With the change in ammo, it is no longer blowing up (although the sticking cases is a pain) Do you think the HS issue can affect the brass casing getting stuck in the chamber?

-

-

Legacy Member

Djandj,

No matter how you slice it or dice it your Bren is not working properly on 54r ammo, either steel or brass cased. Since you had a steel case blow out on rd 3 I doubt the problem was caused by tight HS and heat.

The only other issue I can think of is the cycling problem. Possibly the bolt is opening prematurely because the carrier is not fully forward when the gun is fired allowing extraction before the pressure has dropped. Pretty easy to check but an issue that may be happening sporadically. Could be caused by a weak return spring or something else that causes drag on the carrier return. Before you pull the trigger turn the gun over, muzzle pointed safely downrange of course, and see if the carrier is in the correct position "A" relative to the bolt (see attached pic). You could also hand cycle with dummy ammo. The carrier should end up in Position "A" EVERY time the gun cycles. I found when building my semi that this was a problem to solve before any test firing was done. I think you mentioned in one of your early posts that you did have some recoil spring problems.

It is very difficult to diagnose a problem like this without actually getting your hands on the gun. You might try the gunsmith that Wally G recommended.

Other than that get a .303 barrel and if that works be content with .303 British

Joe

Last edited by Joe H; 05-20-2015 at 07:11 AM.

-

-

JUst been reading and digesting your thread 185 Joe and clearly we HAVE corrected the principle fault that DJ experienced. Brass cased ammo doesn't blow out and there's no sign in the photos that it is going to blow. I appreciate that others guns do work with steel cased ammo, but this one doesn't.

What is telling now is that the brass cases that don't blow out now make extraction difficult by adhering tightly to the chamber walls. Steel cases didn't stick - so by deduction, this tells us one thing. That the fired brass casings adhere to the walls of the chamber harder than the fired steel casings. There's nothing else that would cause the sticking.............

A bit of extra leverage during the primary extraction (PE) phase might help but we ain't got any more PE to help. So tto truly establish this DJ, this is what I'd do next. Slightly oil the brass cases before you shoot them and see how they extract now. If they still sticl like the proverbial 5--t to a blanket then it's a new, accurately re-chambered barrel time OR polish what you've already got.

Like Joe and others have commented throughout. iI's VERY difficult to diagnose a problem like this when it's not sat in front of you. But I'd say that the problem you have now, wqith brass cases sticking, is a LOT less than the original problem!

-

-

Legacy Member

Peter,

Here is why I think Djandj's problem with both steel cased and brass cased ammo is the same problem.

Here is quote from a Hornady technical web page:

Link: Internal Ballistics - Hornady Manufacturing, Inc

Quote:

As the pressure continues to build, the case is forced so tightly against the chamber wall that it cannot move; but since we had a gap between the base of the cartridge case and the face of bolt or breech block - what we termed a little headspace - the case itself must stretch in the head region circled (above, right) to force the case head back.

As the case is moved rearward the primer is reseated in its pocket, when the bullet exits up the barrel the pressure drops, the case cools, and the brass contracts enough to permit extraction of the fired cartridge case from the chamber (left).

IMO in Djandj's Bren the steel case head blows out as it prematurely extracts, the brass case which is much more pliable and may have a better head design also prematurely extracts but does not blow out but still having pressure during initial extraction does not cool down enough to allow proper extraction.

My 2 cents,

Joe

Last edited by Joe H; 05-21-2015 at 07:48 AM.

-

-

Legacy Member

-

-

Legacy Member

Originally Posted by

Joe H

IMO in Djandj's Bren the steel case head blows out as it prematurely extracts, the brass case which is much more pliable and may have a better head design also prematurely extracts but does not blow out but still having pressure during initial extraction does not cool down enough to allow proper extraction.

My 2 cents,

Joe

We agree totally, Joe! Your 2 cents is right on the money! This is just what i said earlier:

"..PRECISELY, JOE!! He is experiencing PREMATURE extraction. As in other replies, the chambered dimensions are TOO LOOSE, there is insufficient obturation of the chamber walls under peak pressures, and the case is moving rearward under that pressure in an unintended fashion. Once the casehead base is exposed in an un-supported fashion, it fails."

-TomH

-

-

Please tell me if I'm barking up the wrong tree but the blowing case problem has been solved by using brass cased ammo - surely. What the problem now is, is EXCESS obturation caused by the fired and still hot case sticking in the chamber. Additionally, the brass case is measurably hotter than a steel case. (We know this from student experiments). So there must be MORE cartridge obturation in the chamber. And being a tapered cartridge case, just the slightest tweak SHOULD break the taper seal. Think morse taper!

Unless the gun is working in blow-back mode, the bullet has to pass the gas port in the barrel before ANY rearward movement of the BB&PAssy can take place. And even then at the 60:1 ratio, the Mech Safety feature ensures that the bullet has long left the barrel WELL before the BB has unlocked.

I realise that I don't truly understand the semi 'rifles' so please feel free to berate me in any way you like. I take it all in good heart..........

Last edited by Peter Laidler; 05-21-2015 at 01:36 PM.

-

.

PM

PM