-

Advisory Panel

Originally Posted by

Patrick Chadwick

Now on the "Reloaders Bench" forum there is a thread "Case head exits rifle" where Parashooter provided the following quite from Hatcher:

"If the bullet had been dipped in grease, this generally meant that the neck of the cartridge was greasy too. The space between the neck of the case and the neck of the chamber was filled with an incompressible substance, and the first moderate rise in pressure found it impossible to expand the neck and release the bullet. Thus the powder was strongly confined right at the beginning of its ignition, and accordingly the pressure rose disastrously."

Looks like you missed the text surrounding that quote from Hatcher -

Originally Posted by

Parashooter

I've noticed that many students of US military rifle lore think of the difficulties encountered with the 1921 "tin can" match ammo whenever lubricated cases are discussed. The actual problem with the 1921 ammo was not case lubricant but bullet lubricant inappropriately applied. To quote Hatcher, "If the bullet had been dipped in grease, this generally meant that the neck of the cartridge was greasy too. The space between the neck of the case and the neck of the chamber was filled with an incompressible substance, and the first moderate rise in pressure found it impossible to expand the neck and release the bullet. Thus the powder was strongly confined right at the beginning of its ignition, and accordingly the pressure rose disastrously." (Hatcher's Notebook, p 341).

As described by Hatcher, this problem was quite distinct from the added breech thrust occurring when the case body is lightly lubed. Although careless application of excessive case body lube could certainly have the same effect, such a result is easily avoided by applying only a very thin film.

The point of this post was to clarify that the pressure problems associated with greased bullets are the result of excess grease preventing the neck from expanding to release the bullet cleanly. This is very different from the added bolt thrust we get when lubricant on the case body reduces friction between case and chamber. NOT THE SAME THING! OK?

When contemplating the waxy lubricant band that used to be featured on Swiss 7.5 ammunition (GP11), don't overlook the fact that the Swiss chamber features an elongated neck designed to accommodate it.

7.5 ammunition (GP11), don't overlook the fact that the Swiss chamber features an elongated neck designed to accommodate it.

Swiss 7.5 chamber neck is significantly longer than cartridge case, leaving room for lubricant formerly applied during manufacture.

There are practical and "approved" uses for lubed cases. Before the development of the fluted chamber (which allows powder gas to prevent adhesion of case to chamber), it was fairly common for automatic arms to employ lubricated cases or chambers. Most of these were MG's or LMG's, but two well-known shoulder rifles, the US Pedersen .276 and the Swedish AG42 Ljungman are documented as requiring lubricated cases for reliable functioning.

AG42 Ljungman are documented as requiring lubricated cases for reliable functioning.

None of this means that lubing your .303 cases and firing them in your Lee-Enfield is a recommended practice. I've been doing it for years with no problems - but I'm a reasonably conservative handloader and my Lee-Enfields are all in sound condition. Some very good people think it's a terrible idea and will damage something sooner or later.

"Longitudinal and radial elongation play a role in creating the stress line that is a prominent feature in the typical Enfield head separations."

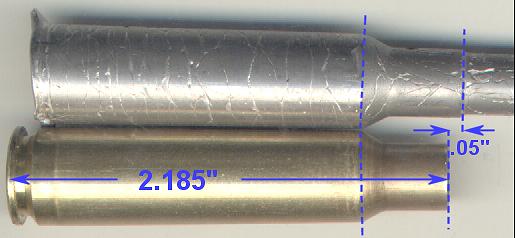

I believe those who assert that radial expansion contributes to the kind of head separation commonly encountered by .303 reloaders are mistaken. Radial expansion puts the circumference of the solid case web in shear, not stretch - and it does so in a completely different location. Failure in this manner is very uncommon with good modern brass and I've never seen an actual example, but here's a lousy picture from an old book that shows what occurs and where -

-

-

06-06-2009 04:21 PM

# ADS

Friends and Sponsors

-

Banned

So ireload2 your main propose here in this forum is to carry on the same argument we had at Gunboards.

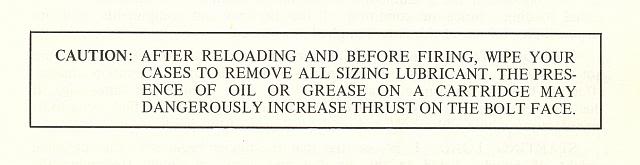

If the ammunition manufactures wanted grease or oil on their ammunition it would come that way from the factory, the ammunition comes grease and oil free and all written material tells you to remove any grease or oil from the chamber.

Ignoring printed warnings to justify your own shade tree methods of oiling or greasing cartridge cases does not justify its use or mean it is safe to ignore these warnings.

I can start a web page and recommend everyone put whale snot on their cartridge cases but the problem is you will NOT find any written material from any ammunition manufacture, reloading manuals or any reliable source telling you to put whale snot, grease, oil or ANY kind of lubrication on any ammunition.

The purpose behind dry oil free ammunition and a dry oil and grease free chamber is to allow the cartridge case to grip the chamber walls and reduce bolt thrust when the ammunition is fired.

Making excuses does not change the fact that your oiling and greasing the cartridge cases will double the bolt thrust, double the strain on the action and more than double the wear on your rifle.

The rubber o-ring method of fire forming cases does NOT require oiling or greasing the cartridge case and does not increase bolt thrust, strain or wear on your rifle.

As I said in the other forum ireload2, please produce any written material from the H.P. White testing Laboratories, reloading manuals or ammunition manufactures telling anyone to grease or oil their ammunition before firing it in their firearms.

Sierra Bullets FAQ:

Question

I don't want to waste my time wiping all the sizing lube off my cases after the resizing operation, but I've been told not to tumble loaded ammunition. Won't some lubrication help the cartridge chamber more easily? What happens if it is not removed before shooting?

Answer

Upon ignition, the case expands in all directions, with the case walls tightly gripping the chamber. Almost instantly, the case relaxes its grip on the chamber walls as the pressure starts to drop, allowing the case to be extracted. If the cartridge were lubricated, the case wouldn't be able to grip the chamber walls, allowing it to slam back sharply against the bolt face. In extreme examples, this force, called "bolt thrust," can even damage a firearm. For what it's worth, the British used to use lubricated cartridges to proof test a firearm, rather than the so called "blue pill" loads used here in the US. Wipe those cases, and make sure your chamber stays clean and dry!

used to use lubricated cartridges to proof test a firearm, rather than the so called "blue pill" loads used here in the US. Wipe those cases, and make sure your chamber stays clean and dry!

Note: The British oiled proof cartridge was used to seat the locking lugs and bolt head because of the additional thrust it exerted. After proof firing the Enfield Rifle was checked with a .067 headspace gauge and if the bolt closed on this gauge the rifle failed proof firing due to excessive set back of the lugs and bolt head.

was checked with a .067 headspace gauge and if the bolt closed on this gauge the rifle failed proof firing due to excessive set back of the lugs and bolt head.

Now what do you think a steady diet of greased and oiled ammunition is going to do to your Enfield rifle.

-

-

Legacy Member

-

-

Legacy Member

The machine gun principle is a red herring in the debate on 303 bolt action rifles. Different beast different action different solutions.

-

-

Legacy Member

One poster reported that his 500 rounds of superior quality HXP brass showed no thinning of the web ---after being fired in a machine gun.

Now is the issue the damage to the rifle or damage to the brass?

A number of countries had no problems oiling cartridges for use in machine guns.

Are machine gun barrels inherently stronger than rifle barrels?

It does illustrate that oiled cartridges are not instant destruction to gun mechanisms. On top of that a machine gun may fire more rounds in 5 minutes than are ever fired in any bolt action infantry rifle in combat. The chance for the oil to cause problems is much greater if it is a real threat.

-

-

Banned

The problem with the internet and gun forums is we have too many people who think they are firearms engineers and they can write or say anything they want.

It is quite obvious that ireload2 doesn’t like being wrong and he will say anything in his defense, as I said before show me any written material from any ammunition manufactures, H.P. White test laboratories, reloading manuals or any reliable source telling you to put ANY kind of lubrication on any ammunition.

You can’t do ireload2 you have no written verification from any notable reliable source and lubing cases is a shade tree home remedy that increases bolt thrust and damages firearms.

And ireload2 you DID NOT answer the main question, you did not supply any reliable written data telling anyone to grease or lube cases before firing.

What you did prove is you came here to argue about something YOU can’t verify or prove with any written material because YOU don’t have any.

The problem with amateur internet firearms engineers is they can’t read or do not understand what they read.

-

Banned

Your posting keep getting progressively more desperate ireload2, if the machine gun was designed from the onset to fire lubricated cartridges then the increased bolt thrust was compensated for in its design criteria and the appropriate components strengthened to take the increased thrust.

What YOU are telling us is to ignore the warnings in the books and manuals and trust your internet engineering expertise.

-

Banned

What many you are missing here is ireload2 and another person wanted to argue about a thread I started at Gunboards using rubber o-rings to fireform cases and got the thread locked down TWICE.

And now ireload2 is here starting it all over again, this thread had been inactive for over 30 days until ireload2 reopened the thread for the sake of arguing further on claims he CAN NOT back up with printed data.

Fire Forming Cases W/Zero Headspace - Gunboard's Forums

Even at Varmit Al’s where he studies case and chamber friction he has a warning at the bottom of his chart warning about lubricating cases.

-

Advisory Panel

Originally Posted by

Edward Horton

. . . show me any written material from any ammunition manufactures, H.P. White test laboratories, reloading manuals or any reliable source telling you to put ANY kind of lubrication on any ammunition.

OK, here's one -

The AG42 Ljungman is a interesting case. It's a locked-breech, gas-operated semi-auto with a direct-impingement gas system and relatively small locking surface at the rear end of the bolt. Perhaps most germane, the Swedish military saved fired cases for re-use. The rifle's operation is fairly violent with Swedish ball cartridges and extractor breakage is a problem with dry ammo. Lube helps preserve the extractor - and the cases.

military saved fired cases for re-use. The rifle's operation is fairly violent with Swedish ball cartridges and extractor breakage is a problem with dry ammo. Lube helps preserve the extractor - and the cases.

Based on the size of the locking lugs, receiver/bolt cross-section, and the distance from bolt face to locking surfaces, it's probable the Ljungman's raw action strength is not very different from a Lee Enfield. The cartridges, 6.5 and .303, also operate at very similar pressure (about 45,000 c.u.p. by US-style radial crusher). It seems case/chamber lube does more good than harm in the Ljungman. Certainly worked in mine.

Again, none of this means anyone should fire lubed cases in their Lee Enfield Rifle . It's just some added information to help folks make their own decisions.

. It's just some added information to help folks make their own decisions.

-

-

Legacy Member

The Lee enfield requires a certain amount of friction grip between the case and chamber to reduce bolt thurst, oiled cases where used to limit the friction to check to see if the lugs were correctly where they should be before the Goverment inspector passed the rifle for Goverment ownership. British Goverment requirement. Machine guns do not require that friction many will not operate with sticky cases hence oil on cases.

Goverment requirement. Machine guns do not require that friction many will not operate with sticky cases hence oil on cases.

-

7.5 ammunition (GP11), don't overlook the fact that the Swiss chamber features an elongated neck designed to accommodate it.

AG42 Ljungman are documented as requiring lubricated cases for reliable functioning.

PM

PM