-

FREE MEMBER

NO Posting or PM's Allowed

Me ... I shoot .308 Win in a No. 5. The rifle´s proofed ... but thank you for the warning ... I´m sure you know so much more than the proof house. I also re-load for my Mauser 33/40. Is that dangerous too? Maybe I should chop them both up for firewood and notify the authorities? Please advise me a.s.a.p.

-

06-23-2009 05:30 PM

# ADS

Friends and Sponsors

-

Legacy Member

Proofed for .308 Win or proofed for 7.62 NATO. There is a big difference.

What proof marks are stamped on the rifle?

Why would you mention a G33/40 in this thread?

-

-

Legacy Member

-

-

Banned

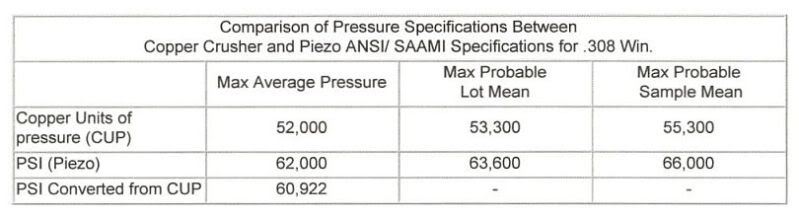

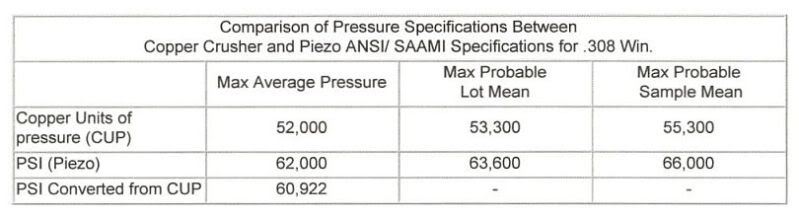

The proof pressure requirements between the .308 and 7.62 NATO are the same, does someone have the wrong information……….AGAIN

There is LESS than 2,000 psi difference between the two rounds

Military 7.62 50,000 cup (proof pressure 67,500) Note: Some 7.62 military is 52,000 cup

Civilian .308 52,000 cup (proof pressure 67,600)

In the attached photos below the pressures are listed as “PSI” BUT they are in copper units pressure pounds per square inch, ALL military manuals are listed as PSI back to the time when Christ was a Corporal (CUP-PSI and NOT transducer PSI)

NOTE: You can shoot .308 and 7.62 interchangeably, they will NOT damage a 2A1 or 7.62 No.4, there is less the 2,000 PSI difference, which is the same difference between military 30-06 ammunition and commercial 30-06 ammunition and we never complained or damaged shooting commercial 30-06 ammunition in our Springfield 03s.

-

Legacy Member

Originally Posted by

Edward Horton

The proof pressure requirements between the .308 and 7.62 NATO are the same, does someone have the wrong information……….AGAIN

There is LESS than 2,000 psi difference between the two rounds

Military 7.62 50,000 cup (proof pressure 67,500) Note: Some 7.62 military is 52,000 cup

Civilian .308 52,000 cup (proof pressure 67,600)

In the attached photos below the pressures are listed as “PSI” BUT they are in copper units pressure pounds per square inch, ALL military manuals are listed as PSI back to the time when Christ was a Corporal (CUP-PSI and NOT transducer PSI)

NOTE: You can shoot .308 and 7.62 interchangeably, they will NOT damage a 2A1 or 7.62 No.4, there is less the 2,000 PSI difference, which is the same difference between military 30-06 ammunition and commercial 30-06 ammunition and we never complained or damaged shooting commercial 30-06 ammunition in our Springfield 03s.

EH you are wrong about the proof pressure of the .308 Win.

Read this and admit you are wrong

.308 Winchester

MAP: 62,000 psi

MPSM: 66,000 psi

Minimum Proof Pressure: 83,000 psi

Maximum Proof Pressure: 89,000 psi

7.62 x 51mm NATO

Maximum: 50,000 psi

Proof pressure: 67,500 psi

Last edited by ireload2; 06-23-2009 at 10:10 PM.

-

-

Legacy Member

Last edited by ireload2; 06-23-2009 at 10:24 PM.

-

-

Banned

Ireload2

Sorry YOU are wrong AGAIN ireload2, do you think I single source the material I put on the internet, do you think I believe 10% of the BS that is written on the internet by anyone with two fingers and a computer.

I worked 34 years at a military depot and the last 25 years were as a Master Level Inspector and the tech library was in the room next to me, over half my life has been devoted to manuals and Quality Control and I can’t believe how many times you have been wrong in these forums and have stepped in your own fecal debris.

YOU do not know the difference between CUP (copper units pressure) and the transducer PSI method of measuring chamber pressures and what the actual differences are.

CUP reads as PSI and the transducer method reads as PSI, BOTH readings are PSI and the Army NEVER changed the way the manuals are written which are “copper units pressure” (CUP) reading in pounds per square inch.

I’m going to be very nice and explain this very slowly……….

Figures are rounded off

50,000 CUP = 60,000 PSI

52,000 CUP = 62,000 PSI

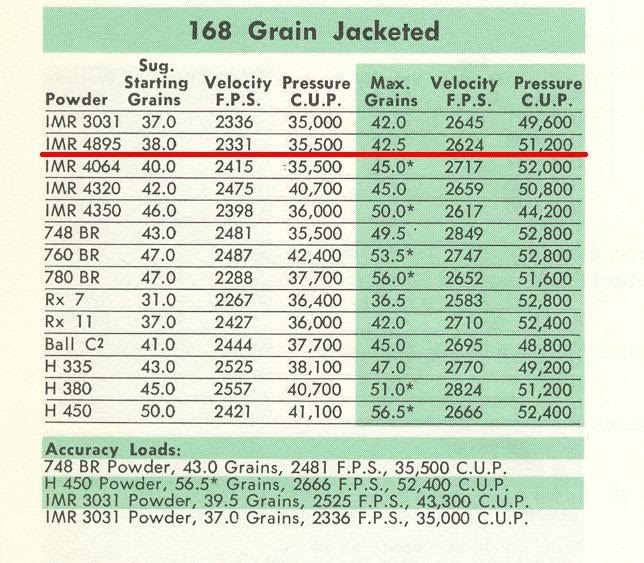

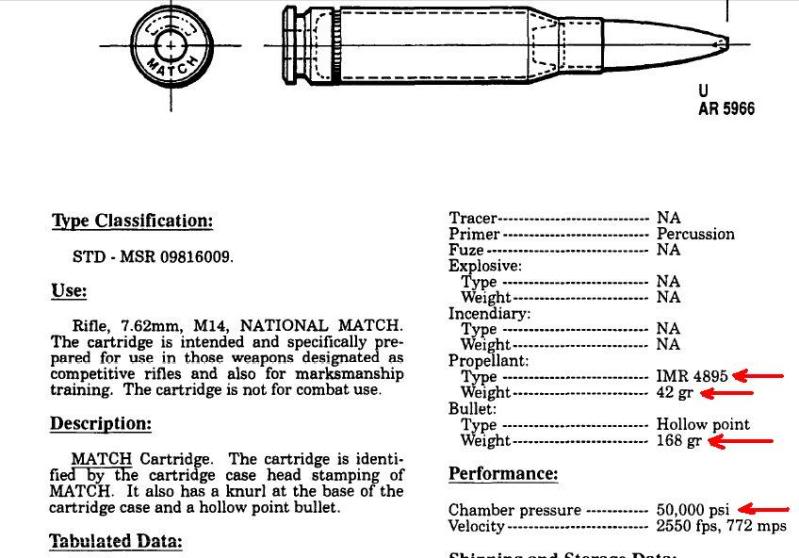

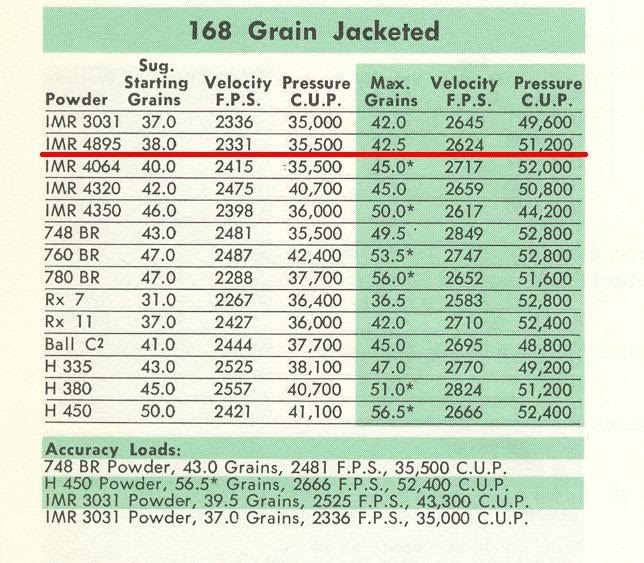

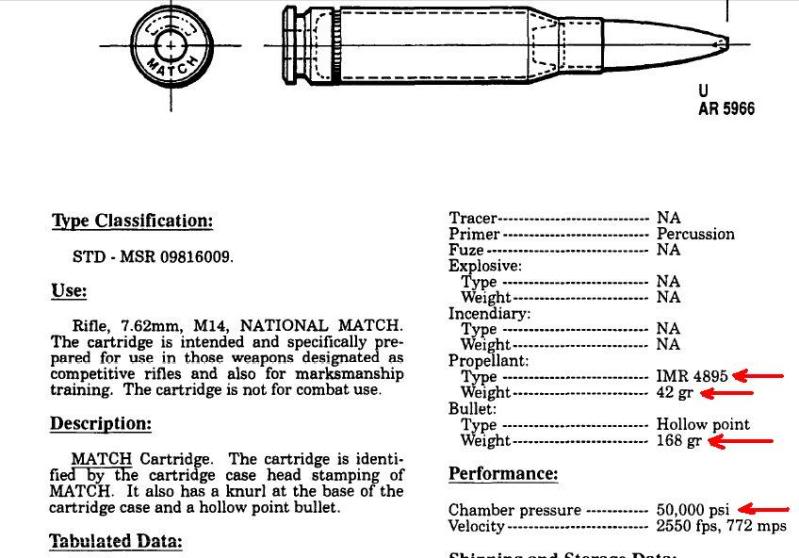

1968 Lyman reloading manual BEFORE the transducer PSI method, please note the IMR-4895 data for the .308 Winchester (42.5 grains at 51,200 CUP)

Army TM on ammunition for the 7.62 Match round (42.0 grains of IMR-4895 at 50,000 CUP) please note there is only one half grain of powder and 1,200 PSI difference between the military match load and the Lyman load for the same weight bullet.

Now how in the hell does half a grain of powder raise the chamber pressure 10,000 pounds by your bassakwards logic meat head.

Take your computer software for guesstimating bolt thrust and pressures and stick it in your ear and then go back to Varmint Al’s and re-read the sections on polishing chambers and the bolt thrust generated, THEN you will understand your computer program figures are off because of friction and the case gripping the chamber walls. On top of this Varmint Al’s muti-purpose $200.00 dollar software program would never compare to what we used at military depots.

And start cross checking and triple checking your information before you post information from garbage websites.

P.S. Please remember I told you I was never wrong and your not holding up well under pressure

Last edited by Edward Horton; 06-24-2009 at 12:32 AM.

-

Banned

Originally Posted by

Dimitri

Excessive pressures or bad headspace/chambers. Norma 8mm Mauser ammunition is loaded to roughly match (relatively speaking ballistics wise) WW2 and post-war 8mm Loadings. Or atleast the specific loading that I buy that Norma makes seems to match quite well. I couldnt tell you right now I'm a few thousands of miles away from the ammunition boxes.

Either way downloading ammunition is not a substitute for using the wrong ammunition. There is a reason why there is "8mm Mauser I" (.318 diameter) and "8mm Mauser IS" (.323 diameter) plus the "8mm Mauser IRS" which is a rimmed .323 caliber round for break actions.

The "downloaded" US sporting ammunition originally used the .321 bullet designed for the .32-40 black powder era cartridge, it was deemed safe enough for use in the undersized bores of the 1888 Commision Rifle and other rifles of that type.

Many Mauser actioned sporting rifles that were being sold at the time used old stock barrels of the smaller diameter.

I believe Norma manufactures ammo of both bullet types, to provide safe ammunition for antique sporters of the earlier bore size.

The L8 was a stop gap measure, the

British

knew they wanted a semi-automatic battle rifle if they were to adopt a new firearm and ammunition, they had trialed the precursor to the FN FAL the FN SAFN49 in 8mm Mauser while Saive was in Britain after the occupation of

Belgium

. Why the SAFN49 and the 8mm Mauser? Because the arms designer was in the country able to work on his rifle he was developing pre-war, and because the British were already manufacturing 8mm Mauser for use in machine guns that did not feed the 303 British well.

I've seen prototypes of the FAL rifles chambered for a 7mm intermediate cartridge, I don't think it was the same cartridge as the .280 British.

They were not going to spend alot of time on the L8, when they had other firearms in the horizon.

And most ammunition degrades with temperature exposure. It is a standard warning on any ammunition, and its in most if not all firearm field manuals from every country, that over heated ammunition is something to be avoided.

And from the article on No.5 wandering zero we now know that .303 No.5 rifles used in tropical environments sometimes spread their receivers. The Cordite ammunition, and probably some other types as well seem to have given excessive pressures under those conditions.

Had LB rifles received the same level of abuse in combat situations they might well exhibit the same spreading of the receiver.

Warnings against use of MkVIIIZ ammunition in No.4 rifles appear to have gone unheeded, according to Reynolds, so this ammunition with its higher average pressure would be very close to the standard pressures of 7.62 NATO. If MkVIIIZ ammunition gave excessive pressures in tropical heat, and there are historical quotes that say just that, then a 7.62 NATO cartridge of even higher average pressure would likely do the same.

Yes and no, standard ammunition that can be fired is great. However interchangeability is confused right now with being the same. As long as it can be fired in everyone elses firearms it was good enough performance was another issue. You can see this with the wide variety of manufacturing differences in NATO countries of 7.62x51mm NATO ammunition, as well as the changes many countries did to their ammunition to suit them, even if it means their ammunition is not identical to everyone elses. The closest thing to a standard for performance and function in ammunition is the SS109 ammunition in 5.56x45mm NATO loaded by various countries.

On several occasions over the years I've seen warnings of 7.62 ammunition showing up on the surplus market that gave excessive pressures and damaged mauser rifles. One I remember was Santa Barbra marked 7.62 that gave pressures of about 67,000 psi. Others gave even higher pressures.

Both Enfield factory conversions like the ones I listed, and the 303 Epps improved rounds used for decades used charges as high as standard 7.62x51mm NATO (or 308Win) and I have yet to hear of one verifiable accident from any of the people I know who own either "conversions".

So I dont honestly see the issue of this "weakness" that is being claimed.

Dimitri

I haven't heard that .308 max pressure level loadings were recommended for the .303 epps, or similar "improved" chamberings.

Modern propellants can sometimes allow high performance with lower pressures than attained with older propellants, or the propellants chosen for factory loads.

While I've seen some stories on various wildcat cartridges on No.1 actions , they seldom make any claims that the rifles were subjected to higher pressures than the max average recommended for the .303.

-

Banned

Originally Posted by

villiers

Me ... I shoot .308 Win in a No. 5.

Is that a Typo?

The rest of your post is no more than an emotional outburst.

Since you are in Germany excessive pressures due to tropical heat aren't an issue. Global warming hasn't progressed that far yet.

excessive pressures due to tropical heat aren't an issue. Global warming hasn't progressed that far yet.

The critiscisms of "Unscientific and weak" bolts were from British and Canadian

and Canadian Sources, and the SMLE was the subject. the improved No.4 action rectified most of the weakness, but not all, as the spread receivers of some rifles indicate.

Sources, and the SMLE was the subject. the improved No.4 action rectified most of the weakness, but not all, as the spread receivers of some rifles indicate.

There are Low recoil .308 loadings that 2A owners have reccomended as best for these rifles, and those owners often reported problems when using full power loads in their individual rifles.

One could chamber a Black Power era Remington No.1 rolling block for .458 magnum and use only low pressure BP handloads in it with safety, but that doesn't mean the BP No.1 is safe for .458 factory loads.

The point of the SAAMI max pressure specification is that not all ammo is created equal, and that while a rifle may be safe enough with some loads it has to be safe with any reasonable load manufactured for rifles chambered for the cartridge type, and have a margin for error in case of ammunition that has degraded in storage.

The cutaway in the left receiver wall of the SMLE appears to have compromised its margin of safety compared to the earlier LE rifles.

If just firing a cartridge wet by rain can fracture the receiver of an SMLE then the claims of it being perfectly safe in the trenches of WW1 become suspect.

Its unlikely that the LE failures listed in the Ross debates could all have been due to wet weather.

Other British sources that I'll post later give information on thermal instability of the service ammunition. Cordite could exude nitroglycerin in cold weather causing excessive pressures, and sweat nitro in hot weather causing explosions of ships magazines and ammo factories.

I've recommended caution in chosing ammunition, thats nothing to get bent out of shape about.

Heres current NATO Proof test figures

7.62 mm (7.62x51mm NATO) Designed to chamber NATO ammunition

(Max pressure for ammunition) 415.0 / (60,190)

(Proof Test for weapons) 519.0 / (75,275)

Pressure recorded in NATO design EPVAT Barrel with Kistler 6215 Transducer or by equipment to C.I.P. requirements

We'd have to see the figures for proof tests of the L8 converted to the system above.

You can't get around the fact that the No.4 was not designed for these pressure levels and that No.4 rifles and No.5 carbines have shown action body spreading after hard use with the cartridges they were designed for.

Also the warning about wet cartridges would have been .303 ammunition of much lower pressures than the least of the 7.62 loads and even lower than the pressures quoted as max .308 loads.

Last edited by Alfred; 06-24-2009 at 04:40 AM.

-

FREE MEMBER

NO Posting or PM's Allowed

Register To Reply

Register To Reply