-

FREE MEMBER

NO Posting or PM's Allowed

Help for newbie with closing bolt issues

So for my first post, after intro, I would ask your help and instruction.... I just bought the Ishapore 762 2A1 and although the bolt will close when no round in it will not when I placed a dummy 308 round in to test it. What can you guys tell me? Where might the problem lie and what steps can I take to solve it??? All thoughts and suggestions appreciated....

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

05-24-2013 01:39 AM

# ADS

Friends and Sponsors

-

FREE MEMBER

NO Posting or PM's Allowed

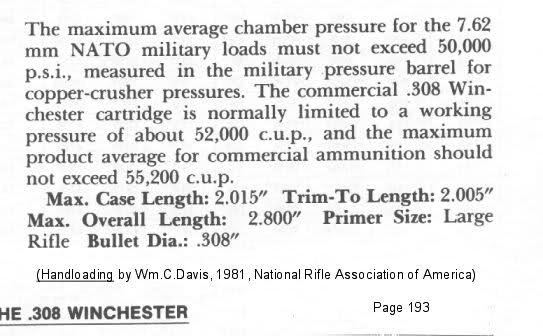

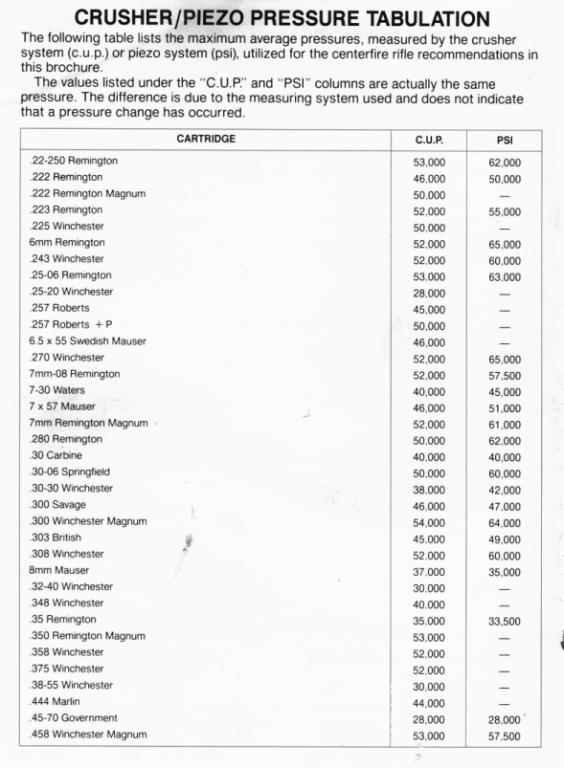

first is have you removed the bolt and checked the chamber ? the enfield had a issue with necks breaking off of brass.the lugs are on the rear of the bolt , tends to flex a little cracking brass . there could be a piece in there.. the larger issue is these rifles were designed for 7.62 nato not .308 winchester. the 7.62 is onlt 50.000 psi and .308 winchester is much higher at around 68.000psi the brass is almost the same, the 7.62 is thicker based clean out the chamber pick up some 168 grain 7.62 ammo and enjoy

-

-

Advisory Panel

I've never heard about the flex of the action causing the cases to break off at the neck... actually I've never heard of a neck being left behind from an extracted case either. I can only imagine where that theory may have came from. Can you please give us a reference so we might investigate?

On another tack, pull your bolt out and check to ensure the chamber is clear of obstructions. Make sure the head of the bolt is wound all the way in before putting it back in the receiver... another thing you might look at before putting it in, is that the extractor claw isn't seized or jammed in with crap in the spring, not allowing it to go over the rim of the case. Don't worry too much about any perceived differences in the metric and imperial sizings for the round.

-

The Following 2 Members Say Thank You to Son For This Useful Post:

-

Advisory Panel

Try feeding the round from the magazine - all Enfields are designed to feed this way, and single-loading into the chamber can cause extractor binding or even spring breakage over time.

Post a photo of the rifle. Due to ignorance over these rifles, its quite possible someone has replaced the bolthead with one which is far too long.

-

The Following 3 Members Say Thank You to Thunderbox For This Useful Post:

-

Legacy Member

Remove the bolt.

Check to make sure the chamber is clean and clear of obstructions.

Make sure the bolt head is fully "screwed on" to the bolt body, In this condition, there should be little or NO gap between the rear of the bolt head and the front of the bolt body. If it overtravels top-dead-centre, it should do so by not more than about 15 degrees at the worst. If it is "out" by one turn, things just won't work.

Look at the bolt head. The extractor should be free to move under the tension from the extractor spring.

If you have 7.62 NATO headspace gauges, use them, if not, find a fellow enthusiast and use the gauges carefully; they are VERY hard and incompressible; Never try to force a bolt closed on a gauge.

If the headspace checks out try your "dummy round" again.

With the bolt in your pocket, tilt the rifle muzzle-down.It should enter the chamber freely and leave the extraction groove just visible in the extractor slot in the barrel. If it is backed out, either the dummy round is defective or there is something nasty going on in the chamber.

For those who do a lot of this and/or a lot of "dry-fire" training, I recommend making up a bunch of "heavy-duty" dummies. My recipe involves scooping up freshly-fired, Berdan-primed, STEEL cases that litter many ranges today. Ditch any that show signs of rust. Wash in a mixture of light oil and denatured alcohol ("Metho" for Australians). Dig or punch out the FIRED primer and drill out the primer pocket . Full-length size (with LOTS of lube), then seat a military style (FMJ) bullet. The final touch is to use the excellent Lee "Factory Crimp" die for the calibre so that the bullet will still be in place after a LOT of "shuffling" through actions and magazines.

You can do the same job with brass cases, and drill a few holes in the side of the case for good measure, but brass ones get shabby quite quickly if you use them for a lot of dry-fire training. KEEP THEM SEPARATED from REAL ammo. (And Vice Versa).

If you are STILL having trouble with chambering, hi thee to a GOOD gun plumber, preferably a Lee-Enfield-savvy one.

Good luck!

Last edited by Bruce_in_Oz; 05-24-2013 at 07:28 AM.

Reason: @%**&$ typos

-

Thank You to Bruce_in_Oz For This Useful Post:

-

-

The Following 6 Members Say Thank You to Parashooter For This Useful Post:

-

Legacy Member

Since it closes with no bullet I'd say its the bullet length maybe COAL or seating depth.? Not to insult you but are you sure your using the right cartridge.?

The way I approach problems is to check the weakest link first,in this case the bullet...

-

-

FREE MEMBER

NO Posting or PM's Allowed

enfield problem

No insult taken, Warpig - I am new to Enfields and have a LOT to learn :-) but I can say it was a 308 shell used, which I know should work, even if not a 7.62 Nato (not that it matters)

I will go through all the advice - many thanks everyone - to see what ails it and if I cannot figure it out it is indeed off to the "gun plumber' to fix - anyone have any recommendations for a good Enfield-knowlegeable one in LA?

As I have 9 days left to wait until it is in my hands anyway, it will be a couple of weeks before the mystery is solved, Watson.

-

Advisory Panel

In the meantime, there is a wealth of knowledge to be had here. Check out some of the members submissions in the MKL , here's some quick links, although all available through the threads at the top of the board...

, here's some quick links, although all available through the threads at the top of the board...

Index Lee Enfield On-line Knowledge Libraries (Index of Articles)

There doesn't seem to be anything particularly on the 2A1, but any of the info on the No1 MkIII gives you a run down of the rifles, and there are a lot here that own them, so plenty of help if needed.

-

-

I think that the answer to your question is being over complicated here Raider............. Heard the phrase 'common problems occur commonly.........' Make sure that the bolt head is screwed fully home, clicked down fully over the bolt head rail and that the cocking piece is aligned with the SHORT cam groove in the bolt. Got that?

NOW try to close the bolt.

Put a drill round in the magazine and now try to close the bolt If it still doesn't close, come back to us.

-

Register To Reply

Register To Reply