-

Legacy Member

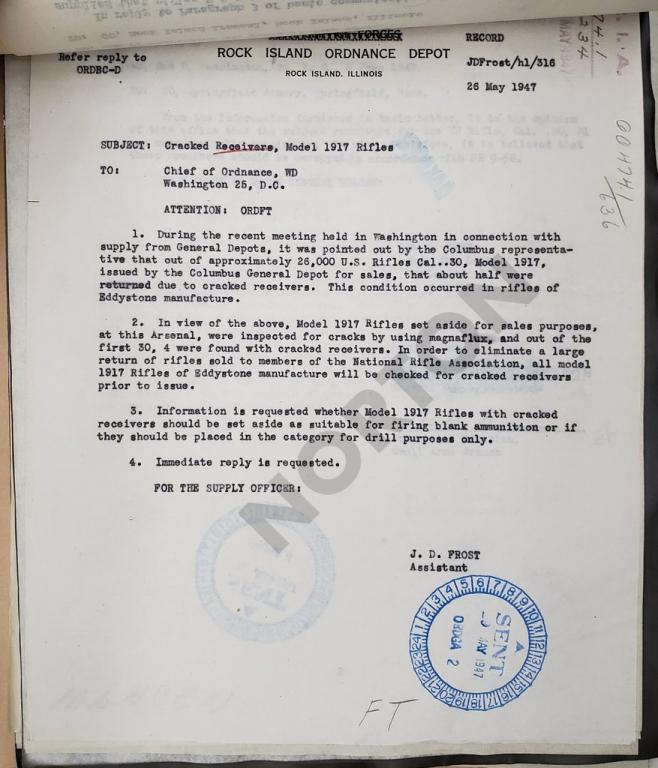

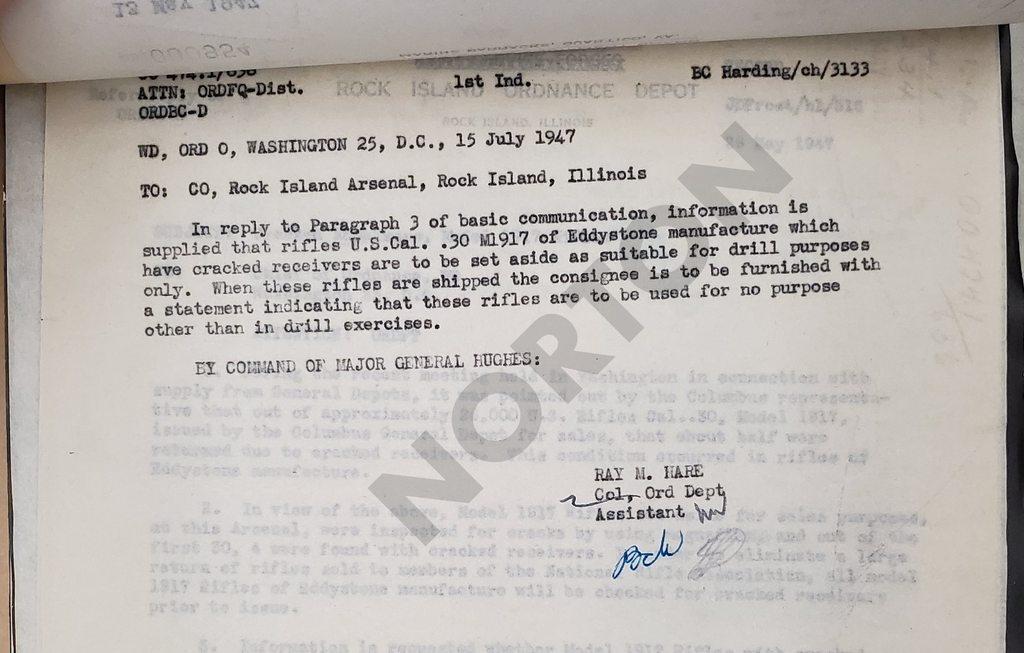

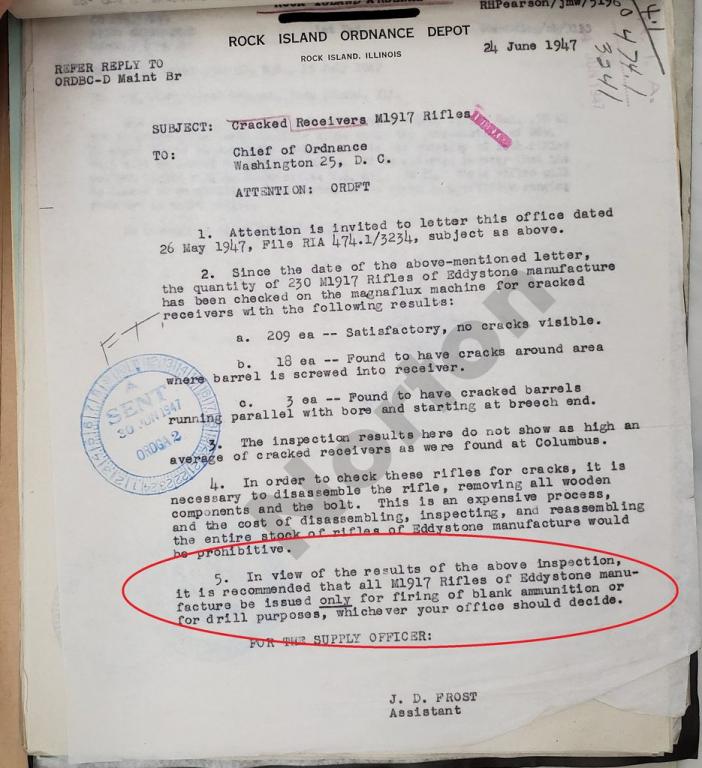

Check your M1917's for safety issues. Eddystones especially..

-

The Following 6 Members Say Thank You to cplstevennorton For This Useful Post:

-

07-26-2019 08:27 AM

# ADS

Friends and Sponsors

-

Advisory Panel

Interesting after all these years. I had an Eddystone myself years back...just like new and shot it regularly. Never occurred to us then that there might be problems.

-

Thank You to browningautorifle For This Useful Post:

-

-

Legacy Member

I'm pretty sure this has come up in the past and is related to re-barreled Eddystones. Something about excess force being used in the process resulting in cracks. I don't think it has been suggested the metallurgy of the receivers was originally a problem as with the low number 03's.

Ridolpho

-

Thank You to Ridolpho For This Useful Post:

-

Legacy Member

I must not have hit submit on the 2nd part.

This seems to extend way past re-barreling. I haven't seen one mention at least that this has anything to do with the ones re-barreled.

-

-

Advisory Panel

I always understood that they could be cracked from original factory barrel installation. I read or was told somewhere many years ago that the reason was there were hydraulic barreling machines being used with semi to skilled labor both male and female doing the assembly in wartime.

-

Thank You to Brian Dick For This Useful Post:

-

Contributing Member

I seen a cracked m17 for sale one time. It was a Remington with a JA barrel. Viewed from the top it was cracked plain as day at about the one o'clock position on the ring and extended back nearly a 1/4". I had read in the past cracking was a problem associated with the Eddystone rifles but had also been found on the other makes to a lessor extent.

I wonder if the cracking and tight barrels could be from the way the threads were cut on the barrels. My understanding is that a certain amount of clearance needs to be apparent on square threads at both the top and bottom of the threads. If the barrels were manufactured slightly out of spec in a hurry I suppose the cracking could occur when the rifle was proofed or later on when it was placed in service.

Something else I observed after working on a few there was a gap where the extractor cut met the inside threads of the receiver. If rifles were allowed to become wet water could easily get in there and freeze but to what extent could that even happen who would know.

-

-

Advisory Panel

I don't care about cracking from a barrel install, I'm listening closely to the suggestion of metallurgy failure. First time this has been past me.

-

Thank You to browningautorifle For This Useful Post:

-

Contributing Member

I don't care about cracking from a barrel install, I'm listening closely to the suggestion of metallurgy failure. First time this has been past me.

I’ve been following and thinking about how to best share my thoughts on this.

Now I think I can just give a, “yeah, what he said!”

Would be very interesting to see more documents pertaining to this.

-

Thank You to rcathey For This Useful Post:

-

Advisory Panel

Originally Posted by

rcathey

more documents pertaining to this

I think Steve has found these in his pouring over things at the library, wish we could just nail it down. I haven't had one for years though... Still, did I miss the part where it talks about metallurgy? Cracks we got...

-

Thank You to browningautorifle For This Useful Post:

-

Contributing Member

-

The Following 2 Members Say Thank You to Doco overboard For This Useful Post:

's with black lights. I assume then everyone can do the same now.

Information

Information

PM

PM