-

Legacy Member

Q. Were not the conversions proofed for the 144gn nato round in use at that time. Therefore any heavier rounds (155gn) would not be covered by that original proof.

-

-

03-23-2010 09:35 AM

# ADS

Friends and Sponsors

-

Deceased January 15th, 2016

Posted to Glynn Alger

First of all you must be getting sick of these letters of complaints about the above but I can only say that you must know who in the NRA started it all and therefore you know who to talk to about their waste of everyone's time.

At the time of the original notice I, and many others to my certain knowledge, asked for references and got, in my case, complete silence.

The latest notice published in the Spring Journal, has done nothing whatsoever to address those questions of fact. In fact it seems to be a thinly disguised justification of the original notice. Some of the points made are general to any firearm and just seem to be there as padding and/or, dare I say, more justification for the original notice. For example bullet point nine – I nearly fell over laughing at that obvious piece of nonsense.

As to bullet point seven. I try to keep my ammunition dry for accuracy reasons but going as far as saying that a No4 is dangerous in the rain beggars belief. They were designed to be used as a battle rifle in all weathers. Has the author never seen newsreels of Far East troops using No4s in the Monsoon!

Finally we are all still waiting for the evidence (not hearsay) that prompted the original notice that has caused so much waste of everyone's time.

Last edited by Beerhunter; 03-23-2010 at 12:45 PM.

-

-

Advisory Panel

Originally Posted by

Bindi2

Q. Were not the conversions proofed for the 144gn nato round in use at that time. Therefore any heavier rounds (155gn) would not be covered by that original proof.

Proof covers the chamber dimension - i.e. the case specification for the designated calibre - up to a certain upper pressure reference. Hence any round of that calibre is ok if it generates pressure under the limit.

-

-

Banned

Strangely Brown and Thunderbox

The proofing laws between the U.K. and the U.S. are light years apart, and our newly manufactured firearms are proofed once in their lifetime here in the U.S. An Enfield Rifle being sold here in the U.S. is sold as an Antique and Curio and by law it is not required to be proofed nor have any serviceability checks or inspections done.

being sold here in the U.S. is sold as an Antique and Curio and by law it is not required to be proofed nor have any serviceability checks or inspections done.

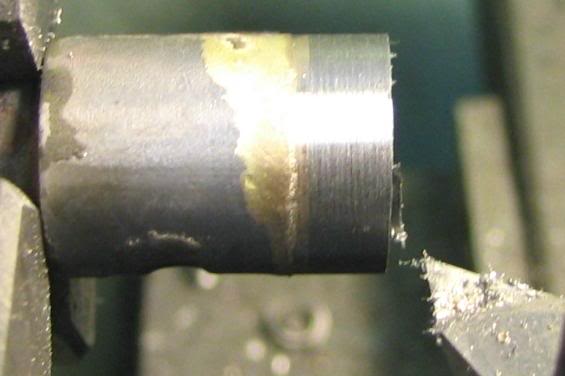

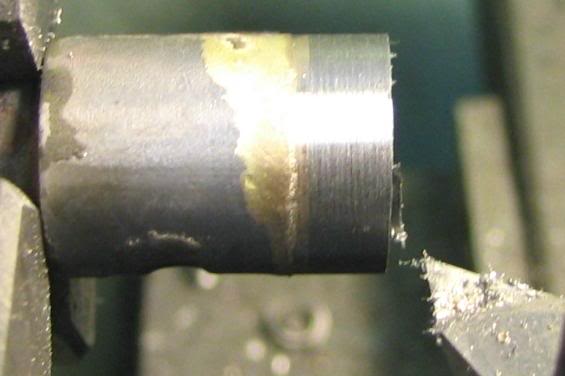

Bolt thrust does have effects on any rifle and if bolt thrust didn’t have any effects on the Enfield rifle the No.4 would not have numbered bolt heads. Below is a photo taken of a case fired in a No.4 Enfield and the backed out primer. With a rim thickness of .058 and a headspace of .074 you would have .016 head gap clearance or air gap between the bolt face and the rear of the case. The photo below shows more than twice that distance and also shows what condition an Enfield rifle can be sold here in the U.S. without any inspections.

Oil, grease or water can double the amount of bolt thrust and does affect the amount of wear, headspace and the useful life expectancy of any rifle. For seven years I have been warning people about oil and grease on their ammunition and in their chambers and water or wet ammunition also comes into play on this subject of increased bolt thrust.

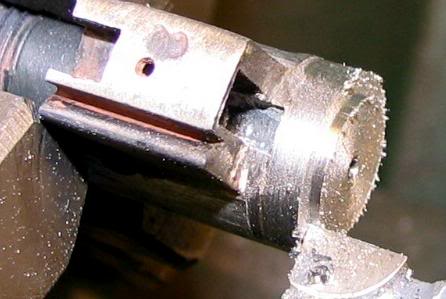

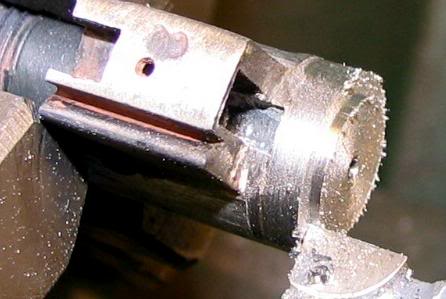

The person who took the photo of his backed out primers was a machinist and he made the “new” bolt head below to solve his problem.

Anyone who thinks that water, oil, grease and bolt thrust won’t have any effect on wear and headspace on their rifles needs to seriously rethink this matter.

Bolt head over rotation is caused by bolt thrust.

GREASE IS NOT THE WORD

”A series of tests at Frankford Arsenal revealed that the use of grease dangerously increased bolt thrust and chamber pressure. When a rifle is fired, the case is driven back against the bolt face with the force of the powder pressure minus the resistance generated by the friction of the expanding brass case against the chamber walls. Grease in the chamber diminishes the amount of friction significantly, and allows almost the entire rearward thrust to operate on the bolt head. With respect to pressure, a test was conducted with 1920 National Match ammunition, caliber .30-06, where the chamber pressure of dry ammunition was noted to be 51,355 pounds per square inch. When the bullet and neck were lubricated with vaseline, the pressure rose to 59,000 pounds per square inch. When the tests were repeated with the entire case being lubricated, pressure soared to 71,154 pounds per square inch, and destroyed the pressure gauge.”

Firearm Technical Trivia, January 2001

-

Ed,

I don't think anyone is arguing about the influence of oil, grease or water on ammunition and the increased pressures. This is generally accepted by all from what I read.

This thread is about No.4 actions converted to fire 7.62 Nato ammunition. What is being asked is - " What actual evidence exists of failed No.4 actions to substantiate them being singled out by the NRA in the United Kingdom , and imposing these additional requirements on them."

, and imposing these additional requirements on them."

Last edited by Amatikulu; 03-23-2010 at 12:44 PM.

-

-

Banned

-

Advisory Panel

Originally Posted by

Edward Horton

....It is my understanding the older oiled proof round testing system was discontinued because the repeated testing in this manor was actually causing damage to the firearms. (excess bolt thrust)....

I'd hazard a guess that the oiling was introduced to enable the generation pressures that the propellants of the time may not have permitted in many case sizes, and that modern propellants have made that step unnecessary.

Going back a bit in this thread, bolt head overturn is surely caused mostly by simple mechanical wear to the contact surfaces on the threads of the bolt head and bolt sleeve, together with wear to the front face of the bolt sleeve where it contacts the rear face of the bolt head. As the threads wear, they take less of the thrust, allowing the bolt sleeve face and bolt head rear face to wear against each other with more and more force, causing accelerated wear of those surfaces. I've seen a few boltheads with quite striking grooves worn in them by the front of the bolt sleeve. Now I could be wrong about this, but it seems to me it would make more sense mechanically to have the thrust taken by the far larger surface area of the threads than by the forward face of the bolt sleeve,, as has been suggested here and in another thread.

Likewise the “setback” of bolt lugs and recoil lugs in the body. Is there any scientific proof that the steel in these areas is “compressed” or displaced? Surely the loss of dimension on those surfaces is caused almost entirely by simple mechanical wear as the surfaces rub against each other every time the bolt is opened and closed?

But perhaps I'm just misunderstanding...

Last edited by Surpmil; 03-23-2010 at 02:14 PM.

-

-

If I recall correctly, the United Kingdom adopted the metric system in the late 60's. That makes me think that a L42A1 with a 19 ton per square inch proof stamp needs to be converted to pounds by multiplying it by 2240 lbs in an Imperial Ton.

adopted the metric system in the late 60's. That makes me think that a L42A1 with a 19 ton per square inch proof stamp needs to be converted to pounds by multiplying it by 2240 lbs in an Imperial Ton.

That gives me 19 ton = 42,560 psi as a proof by whatever method was in use at that time.

Assuming the 19 tons referred to the maximum average working pressure and not the proof pressure, that means in simple terms that the rifle would need to be re-proofed > 41.42% higher!!!!

It seems unlikely to me that even with different test methods, 19 tons proof will not be equal to 26.87 tons proof.

The conclusion is that the NRA (UK) wants all the No.4 rifles used under its auspices to be re-proofed to this newer standard

-

-

Legacy Member

Hi All,

Today I received the NRA Journal (Spring 2010), from the NRA of the UK . This had information on the Lee Enfield’s “being unsafe”. I know this has caused much debate in previous posts. I have found that the article on page 57 by Dr E Blakely very interesting. I dont know if they have published this yet but I enclosed a link to the journal for you to look at: -

. This had information on the Lee Enfield’s “being unsafe”. I know this has caused much debate in previous posts. I have found that the article on page 57 by Dr E Blakely very interesting. I dont know if they have published this yet but I enclosed a link to the journal for you to look at: -

http://www.nra.org.uk/common/asp/general/journals.asp?site=NRA

-

-

Banned

If I recall correctly, the

United Kingdom

adopted the metric system in the late 60's. That makes me think that a L42A1 with a 19 ton per square inch proof stamp needs to be converted to pounds by multiplying it by 2240 lbs in an Imperial Ton.

That gives me 19 ton = 42,560 psi as a proof by whatever method was in use at that time.

Assuming the 19 tons referred to the maximum average working pressure and not the proof pressure, that means in simple terms that the rifle would need to be re-proofed > 41.42% higher!!!!

It seems unlikely to me that even with different test methods, 19 tons proof will not be equal to 26.87 tons proof.

The conclusion is that the NRA (UK) wants all the No.4 rifles used under its auspices to be re-proofed to this newer standard

Amatikulu

The British used the axial method of proof testing with the copper pellet at the very rear of the case and also oiled the case.

The 19 ton = 42,560 axial psi figure must have 10 to 20 percent added to get the equivalent of our American radial method of measuring chamber pressure.

The 19 tsi figure must be “recaliberated” as follows:

19 ton = 42,560 + 20% = 51,072 CUP or “Normal operating pressure”.

(52,000 CUP is approximately 62,000 PSI transducer method)

We need to find out what the exact number of tsi proof pressure cartridge that was used and convert to a more modern reading. If the oiled axial proof test round was approximately 37,625 tsi = 75250 PSI trandsducer method, then the converted 7.62 Enfield Rifles had twice the bolt thrust applied to them during proof testing than a dry modern CIP proof test round that the British NRA want them retested to now.

had twice the bolt thrust applied to them during proof testing than a dry modern CIP proof test round that the British NRA want them retested to now.

We need to find the actual older oiled tsi proof testing pressure figure and not the 19 tsi figure that is the normal operating pressure of the 7.62 NATO. (50,000 CUP or 60,000 PSI)

It is also my understanding that possibly two military proof rounds were fired, I have read that one dry and one oiled proof round was fired. The dry round to "proof" the barrel and the oiled proof round to test the action.

Correlating PSI and CUP

http://www.shootingsoftware.com/ftp/psicuparticle2.pdf

(Under the British base crusher standards described below, proof loads ran 30 to 45% above normal. To maximize breech thrust, proof cartridges were oiled before firing.)

In Britain, a third set of crusher standards were developed, using a "base" crusher. The crusher was a short, thick tube placed behind a piston at the base of the cartridge, and the firing pin passed through the center. The cartridge case was well oiled before firing, to minimize cling to the chamber walls (if not oiled, the indicated pressures were about 25% lower). To prevent case rupture on set back of the base, the crusher was first deformed in a press to a pressure a bit lower than that expected in firing. The units were generally stated in British long tons per square inch, or tsi. Pressures indicated by this method run 10 to 20% below those indicated by radial crushers. Kynamco in England still rates their production cartridges with this method.

Cartridge Pressure Standards

PM

PM