-

Originally Posted by

jmoore

Apparently the CAF SBD has dramas. Just now got done looking at it. Looks like major oil leak coating the rear flight surfaces. Ailerons and some fairings are off. If it's in for repaint it'll be a little sad as it has a nice weathered appearance right now.

Are you talking about the oil in this photo? All these radials spew oil constantly and have to be wiped down after every flight. It looks like someone started to wipe it off after it's last flight, but didn't do much. You need to put a big pan under the engine as soon as you stop flying to catch all the residual oil that drips out. Not usual to have a quart or so in the pan all the time. Each cylinder is on it's own in a radial motor and they just leak constantly. You chase the worse leaks, but really worry when it stops leaking (because you're out of oil)

Cowlings come off routinely - They're under constant maintenance and they were always like that, even when new.

Are you talking about the dive breaks? (Do you have more photos?) I just checked the Dixie Wing Schedule and the SBD is still on schedule for appearances through the next few weeks.

It's not likely it'll be repainted any time soon. They did a major livery change to the tri color early scheme about ten years ago and it should remain that way for years. It costs a small fortune to repaint and it isn't usually done unless it's completely worn out.

-

-

06-17-2011 09:21 AM

# ADS

Friends and Sponsors

-

That's good to hear. Must have been some "minor" control surface maintenance. But the oil leak was more than usual, so... It's hard to get much info at 3AM

Yah, I've worked around "round motors" a bit. Used to be a freight doggy bunch flying C47s and DC3s at an airport where I was doning Warbird stuff. They owned the oldest DC3 on the planet, but it's not flying. Oh, and THREE C54/DC4 Carvair conversions!

I guess my point is that at this point these airframes are a nonreplacable consumable resource. They WILL become increasingly un-airworthy due to corrosion, vibration, hard landings, fires, powerplant failures, pilot error, hail, hurricanes, etc. etc.

To build new, we need good assmblies and parts. The factory drawings aren't enough!

BTW, I've built stuff enough for various aviation museums (static display) to be highly unimpressed. No, more like shocked and disgusted, but it's been a while- long enough to not go on a huge rant.

Keep 'em flying, but think to the future- you'll need some more airframes. Or does it all go virtual?

ETA, no NOT the dive brakes! Ailerons. Much less complex! (I can't remember if they used my tooling to do new dive brake skins back in the '90s or not. I did a static set that hangs in the Naval Air Museum wall, and some for a "real" flying SBD, but don't remember whose- may have only been a partial skin... Sorry, rambling! Trying to remember old stuff!

ETA2: Note the lack of control surfaces at the far left of the photo outboard of the dive brakes:

I did this stuff seven days a week for eight years, but it was killing my health and pocketbook!

Last edited by jmoore; 06-17-2011 at 12:09 PM.

-

-

-

I think I know what you mean about the parts. Good aviation fabricators can build almost anything if they have the original part to work from (or what's left of it) -

There's a few who are fantastic. There's a place in Texas called Ezell's where most everyone here farms out important parts. I've seen some sections of skin with compound curves, etc and good aviation fabricators can make brand new airworthy parts from scratch that look like carbon copies. (They're expensive though)

You're correct about corrosion too. Aluminum 'cancer' is a real problem with a lot of old parts, and many are'nt easy to access to inspect. These planes were built at a time when they weren't intended to last more than a short time and they didn't design in a lot of inspection plates, etc just for inspecting for corrosion. It's common to need to drill out rivets on these old planes so you can see inside. Lot's of wing spars have been rebuilt from scratch by good fabricators.

Last edited by Harlan (Deceased); 06-18-2011 at 11:38 AM.

-

Thank You to Harlan (Deceased) For This Useful Post:

-

Originally Posted by

cafdfw

Lot's of wing spars have been rebuilt from scratch by good fabricators.

The folk in the US have been lagging far behind the restorers in the UK where critical parts like spars and wing builds are done in jigs to ensure proper geometry. I know of one early P40 that has poor flying qualities because the wings were build on barrels. There's not only straightness to consider, but the airfoi should have a slight "twist" as it goes outboard as designed. Hard to get right or consistant from side to side w/o guides and locating points!

where critical parts like spars and wing builds are done in jigs to ensure proper geometry. I know of one early P40 that has poor flying qualities because the wings were build on barrels. There's not only straightness to consider, but the airfoi should have a slight "twist" as it goes outboard as designed. Hard to get right or consistant from side to side w/o guides and locating points!

Hopefully the situation has improved over the past ten years.

-

-

Some minor updating and some "leftovers" that have turned up:

The SBD WAS in for a new coat of paint, but I don't have new photos.

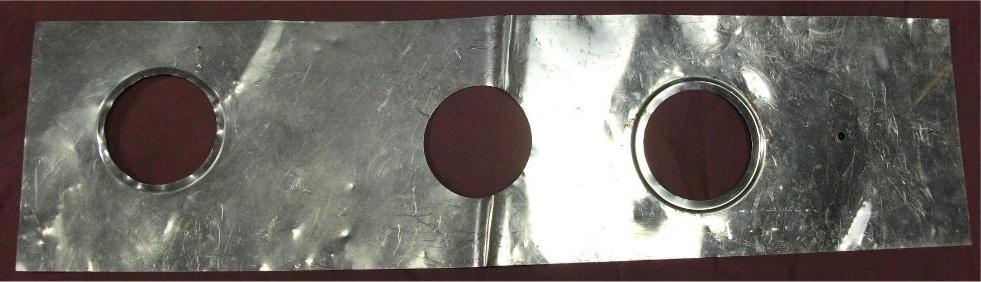

Meanwhile, this old scrap bit of aluminum was found that was used when I was testing the SBD dive brake hole punching and forming tools that I was making. (Tools ended up I don't know where, sadly- the owner died some time ago.)

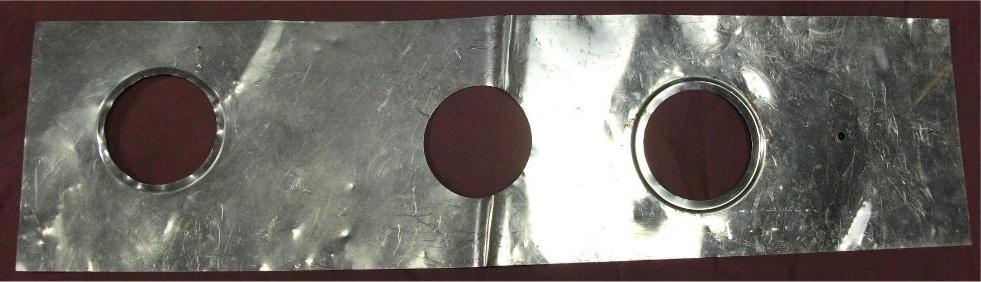

Also found some P40 brackets that are still "in process":

(Copied off an original forging- It just doesn't look the same when merely programmed into a CNC.-It's an "analog" part. Plus, I "upsized" it about 10% where possible to compensate for the lack of the originals' forged grain structure- It also is of stronger 7075 aluminum which we shotpeened as well- to help life in a high vibration enviroment. )

Made a blue million of these little Curtiss bits, too, many using a 24" universal shaper, which was kinda slow for larger runs:

Four thumbs up "smilies" if you can specify where the above parts go!

If you have "straight" original parts- even corroded, you can build new, using the old as patterns. But wing and fuselage jigs need to be made before the last airframe of whatever type becomes "bent", destroyed or otherwise unaccessible. Drawings just won't get you where you need to go.

-

The Following 3 Members Say Thank You to jmoore For This Useful Post:

Register To Reply

Register To Reply