-

Legacy Member

Lee Enfield: Am I Making A Mountain Out Of A Molehill?

I am intrigued by the idea of casting bullets for my No.1 Mk.3 and have accordingly slugged the throat and determined it to be .314. So, in order to have the recommended .001 oversized bullet, do I cast the bullet at .316 and size it at .315? Or cast and size at .315?

Am overthinking this?

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

-

01-08-2021 03:31 PM

# ADS

Friends and Sponsors

-

Advisory Panel

Size to .315, if you cast big and size down it's the same. Casting from a .315 mould might shrink a touch. Depends on your material. I'd want to use a gas check too.

-

-

-

Legacy Member

314 at the throat?

LOOXURY!!

They can run out to .319" nominal groove diameter and STILL meet the acceptance specs on the drawings.

The catch with cast bullets is that if yyou opt for long, heavy ones, they may not stabilize at "workabl velocities, even in the 1:10" twist, in good condition.

If you go stuffing "fat" bulletd into a standard case, the resulting neck diameter may cause issues with fully seating in the chamber. SMLE chambers were all, to the best of my knowledge, reamed with LONG throats, because initially, they had to be able to handle the long, heavy torpedoes of the Mk 6 round. This throating was maintained LONG after the Mk 7 spitzers came on the scene, initially because there were still BILLIONS of Mk 6 cartridges in the "system".

Most of the Commonwealth troops who went ashore at Gallipoli in 1915 were issued with Mk 6 ammo, not just because "it was there" but because almost ALL of the rifles and machine guns were regulated and sighted for Mk 6 ammo. This supply situation rapidly changed as the war rolled on, but the barrel spec remained to be able to handle Mk 6 ammo, even after the sights had been "reworked" to handle the different trajectory of the Mk 7.

All that said, it is not a realistic goal to match Mk 7 or even Mk 6 with a cast bullet, gas-check or not. The only remaining caveat is that the 1:10" twist will do nasty things to any but the hardest cast bullets at almost any velocity. Use the hardest alloy you can find and cast, stick with shorter, lighter bullets and "milder velocities. Final, Final caveat IF you EVER attempt to shoot jacketed ammo without totally "de-leading" the barrel, you WILL "ring / bulge" the bore. I've seen it happen on a couple of expensive "collectibles"; tears before bed-time!

Round-ball "gallery" loads can be fun and very cheap to run, but the "leading" warning remains.

-

The Following 7 Members Say Thank You to Bruce_in_Oz For This Useful Post:

-

Advisory Panel

Time you wrote a book, Bruce in Oz!

“There are invisible rulers who control the destinies of millions. It is not generally realized to what extent the words and actions of our most influential public men are dictated by shrewd persons operating behind the scenes.”

Edward Bernays, 1928

Much changes, much remains the same.

-

-

Legacy Member

I use a Lyman 314299 which was originally designed for the 303 British . Night Owl Enterprises or NOE makes a bullet mold based on the Lyman 314299. It does cast a fatter bullet at .316, don't have the web address but google will take you there. I don't think Lyman makes a .316 H&I or sizer die in this size. So you might wish to visit the cast bullets website. I believe there are a couple members who do make custom H&I or sizer dies. And you might get away using the top punch for the Lyman 314299. Hope this helps. Frank

. Night Owl Enterprises or NOE makes a bullet mold based on the Lyman 314299. It does cast a fatter bullet at .316, don't have the web address but google will take you there. I don't think Lyman makes a .316 H&I or sizer die in this size. So you might wish to visit the cast bullets website. I believe there are a couple members who do make custom H&I or sizer dies. And you might get away using the top punch for the Lyman 314299. Hope this helps. Frank

-

-

Legacy Member

Originally Posted by

greggordon52

I am intrigued by the idea of casting bullets for my No.1 Mk.3 and have accordingly slugged the throat and determined it to be .314. So, in order to have the recommended .001 oversized bullet, do I cast the bullet at .316 and size it at .315? Or cast and size at .315?

Am overthinking this?

You may not be overthinking it enough! But you're off to the right start in my opinion and experience when you slugged and measured your barrel.

There's a lot at play here. For example, if you cast/size to +.001" over throat size, how are you going to fit that bullet into the throat? Especially if you're working with bore riding designs like the ubiquitious Lyman 314299 as one example?

(BTW, you're probably thinking of the old "size .001" over groove diameter" platitude; if you're lucky that MIGHT get you close to matching the actual ball seat/leade dimensions, which is what you actually want to match)

In my experience and opinion, you want your seated and chambered cast bullets to just barely have clearance in the ball seat/lead. That area is almost certainly not cylindrical in shape i.e. you can't equally size the portion of the bullet that will be positioned within the ball seat/leade prior to firing, you'll only size part of what is part of a slightly tapered section. That may not make any difference - or it might make a whole bunch of difference, nobody can say. An interference fit in this portion of the chamber can be dealt with by slightly sighting the bullet deeper, of course, depending on how much oversize this portion of the cast bullet is.

Having slugged your ball seat/leade, you can look at the dimensions of available moulds and pick one that will drop bullets close to matching that section, where any sizing only touches the portion of the bullet that is within the case neck.

For some people and some uses i.e. casually killing tin cans with inexpensive cast bullets, this may seem to be just time wasted trying to pick fly poo out of pepper. But with rifles like the Lee Enfields that have such a great variation in chambers, especially the well used ones, if you really want to get the best possible performance out of cast bullets in your milsurp, the time spent in determining ball seat/leade dimensions and matching your seated cast bullet to closely fit that can make an enormous difference.

Depending on what velocities you load to, you may or may not need a gas check. In these days of scarcity, a lot of bullet casters are trying to find a way to avoid using them.

When I was conventionally lubing for my Lee Enfield, loads at 1400 fps and slower didn't gain anything from using a gas check, so I left them off. After converting to powder coating, reloads at Ed Harris's "The Load" velocities/pressures (~1600 fps) were usually fine without a gas check. Usually fine, but not always.

Powder coated or not, everything over those pressures/velocities needs a gas check as most powder coating bullet casters have found.

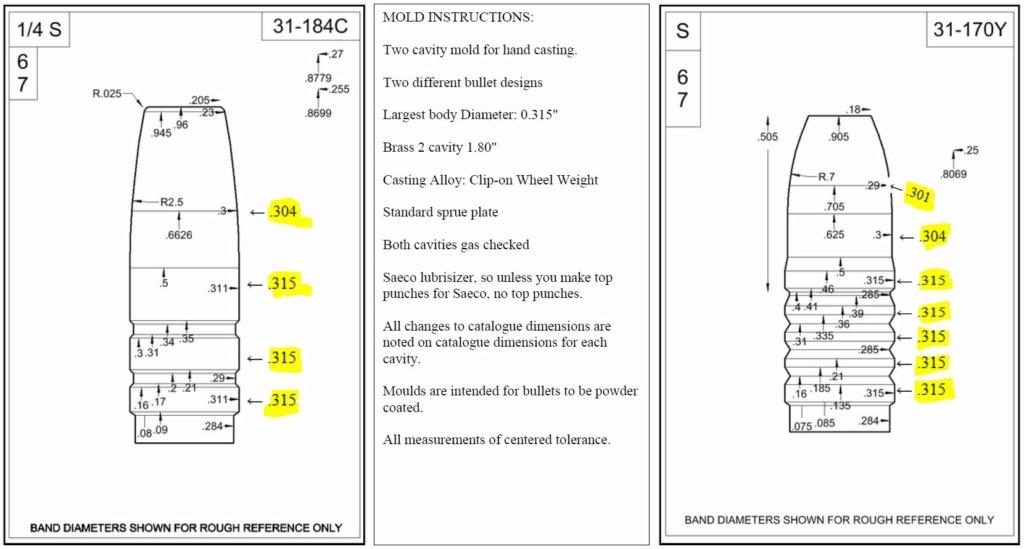

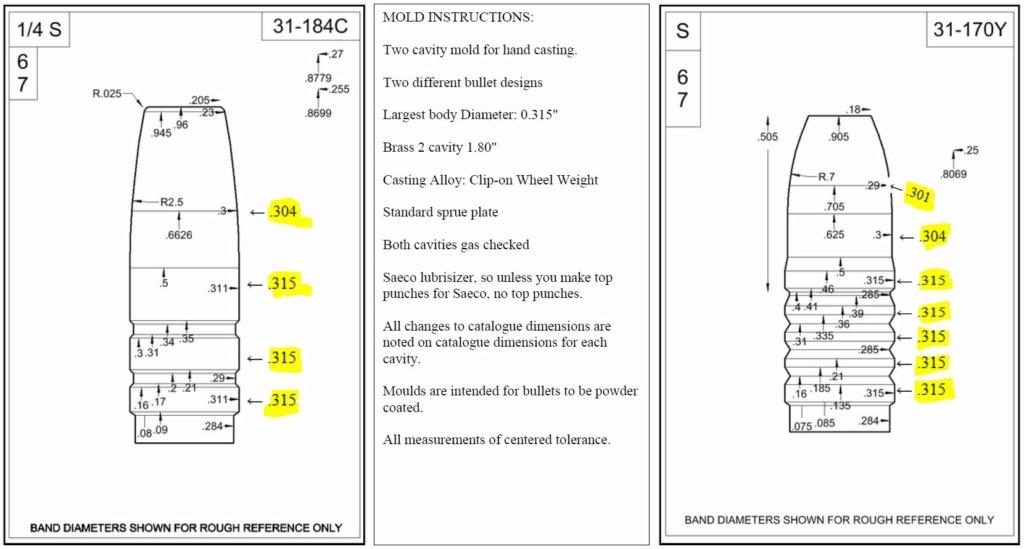

Accurate, NOE, and other custom bullet mould makers offer a variety of bullet moulds intended to try and match real world Lee Enfield ball seat/leades than theoretical measurements and barrels where the bore is always .303" and the groove .311". Many offer a chubbier version of Lyman's 314299 for example.

My opinion only after some trials with a Lyman 314299, is that it is not the best shape weight for ideal cast bullet performance, even though many do say they're satisfied with it. I have a pristine barreled 1950 Long Branch that was unissued when I got it; performance with long heavy bullets like that is mediocre. Performance with shorter/lighter cast bullets is exceptional.

Full disclosure, considering how much money I spend on my milsurp shooting hobby, a custom built mould that drops bullets that precisely fit my ball seat/leade is money where every cent they cost was well spent.

-

PM

PM