-

Legacy Member

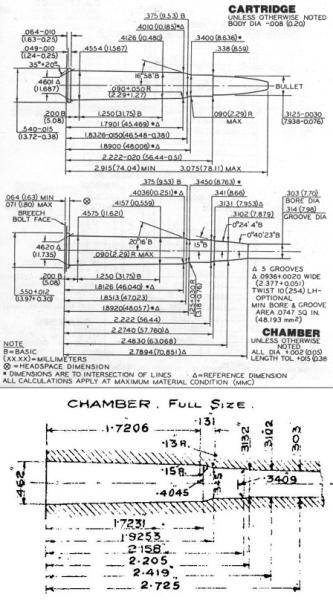

.303 British Maximum cartridge drawing.

Does anyone have a fully dimensioned drawing of the .303 British maximum cartridge as standardized to be fired in Lee-Enfield rifles?

maximum cartridge as standardized to be fired in Lee-Enfield rifles?

I need the max cartridge drawing so I can compare it to the minimum standard .303 rifle chamber. Thanks

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

-

03-09-2010 08:43 PM

# ADS

Friends and Sponsors

-

FREE MEMBER

NO Posting or PM's Allowed

.303 diagrams

Moderator Edit: Fixed pic links for member so they would display properly ...

Last edited by Badger; 03-18-2010 at 06:27 PM.

-

Advisory Panel

Thanks for posting the pics Zippy7.

I have a little difficulty in interpreting these two drawings.

Pic without bullet: case length 2.22"

Pic with bullet: case length 2.222"

Fairly closely the same, and plausible if the pic without bullet represents the maximum case dimensions.

The shoulder angle is 16.6 in both cases, but:

Pic without bullet: base-shoulder 1.786", neck length 0.304, shoulder 0.393"

Pic with bullet: base-shoulder 1.790", neck length 0.332", shoulder 0.401"

If the pic without bullet represents the maximum cartridge, and the pic with bullet is the minimum chamber, then I am worried by the max neck diameter being 0.339" and the minimum chamber (at the neck) being 0.338". And the 0.304" neck length seems plain wrong. Perhaps someone could help me with the interpretation of these drawings?

I am not being just picky here. There has been such a lot of heated discussion of Enfield cartridges in the past on this and the old CMP forum, in the course of which a couple of contributors managed to get themselves banned, that I feel it is important to be sure that any data presented are correct (as far, of course, as the contributor can judge).

forum, in the course of which a couple of contributors managed to get themselves banned, that I feel it is important to be sure that any data presented are correct (as far, of course, as the contributor can judge).

This requires stating the source of such information and, if possible, the date of the drawing. I suspect that the maximum dimensions may have altered over the decades. All I know for certain is that the base-shoulder distance on my arsenal-mint (i.e. banged around in storage, but otherwise apparently unused) examples of a No. 1 MKV and No.4Mk2 do not match in this respect, and in both case the shoulder is much, much deeper than on cartridges formed in modern sizing dies. I live with this by segregating the cases for the two rifles and neck-sizing only (yes, I even have two sizing dies, for this very reason).

So I too would like to know what the "real" British standards were, at a given time. But from official drawings - if anyone has such.

standards were, at a given time. But from official drawings - if anyone has such.

Patrick

-

-

Legacy Member

The .303 is a little like sausage -mystery meat.

With the abundance of British documentation it seems like a British military standard format drawing would be available. This needed drawing should show the maximum permissible cartridge dimensions for easy comparison to the smallest permissible chamber dimensions.

documentation it seems like a British military standard format drawing would be available. This needed drawing should show the maximum permissible cartridge dimensions for easy comparison to the smallest permissible chamber dimensions.

-

-

I'm not sure what else is in these two old scanned books, but about 500 or so pages into the 1915 version, there's several pages discussing the .303 cartridge, including color plates.

The two "out of print" books can be found in the Technical Articles for Milsurp Collectors and Re-loaders (click here)

(Copy PIC to Enlarge)

(Copy PIC to Enlarge)

1905 Treatise on Ammunition (click here)

1915 Treatise on Ammunition (click here)

Regards,

Badger

-

-

-

The Following 3 Members Say Thank You to Parashooter For This Useful Post:

-

Just going by the dimensions of fired cases from multiple examples of weapon types, there's several "families" of 303 SAA chambers. Whether the CARTRIDGE dimensions changed over time, well, that's an issue better left to cartridge collectors.

Weapons w/ similar chamber dimensions:

1.SMLE- British , Indian, Australian

, Indian, Australian

2.Pattern 1914

3.Ross (Small)

4.Ross (Big)

5.No.4 Mk.I, No.4 MkI*, No.4 Mk.2, BREN

Not enough samples of other types to make any guesses. I'm not saying they're exactly interchangable, just close, from weapon to weapon.

I DO have several SMLEs and No.4s that can interchange neck sized reloads i.e. - SMLE to SMLE, that's what got me to checking.

-

-

Legacy Member

JM,

Do your chamber shoulders remotely resemble the shape of unfired ammo?

-

-

Advisory Panel

Very good Parashooter. The top drawing is the first one I have seen with any tolerances. Looks like a plausible specfication drawing (at last!). Could you please give us a source reference?

The second drawing illustrates the problem. The (presumably minimum) chamber depth to the end of the neck is given as 2.158".

But in the top diagram we can read the corresponding dimension as 2.222 (presumably absolute minimum) minus the maximum recess for the rim (0.071") = 2.151. You will only get the 2.158" with a minimum rim recess!

So if you are one of those who like to leave the cartridge as long as possible, and chamber a cartridge that is more than 2.151 long beyond the rim, for instance because the OAL is OK, but the rim has the minimum thickness, then you may be getting a neck jam when the firing pin rams this cartridge forwards.

Not good for pressure, I believe. An example of how a derived drawing that leaves out tolerances can lead to grave problems of interpretation.

Take that maximum rim recess of 0.071", combine it with the minimum rim thickness of (0.064-0.010")=0.054" and you have a head clearance of 0.017" plus any gap between bolt face and back of chamber when firing those actual cartridges in that actual rifle. Similar effect at the shoulder, but it is getting late over here and someone else can check it out.

Ireload 2, I think I know what you mean by the shoulders. I have a lot of PMC cases. The first time I looked at the fired cases, the shoulder had been reformed so far forwards that, thinking the cases would be to spec. I wondered if my No. I MKV had been rechambered to .303 EPPS. Not so of course, it is the cases that must have been made to the absolute minimum dimensions. See the drawing posted by Parashooter.

Maybe I'll check it all through tomorrow, if someone else hasn't already done so, but it seems to me that cartriges made to absolute minmum specs are going to have an awful lot of space at both ends on first firing.

No wonder that those minimum-dimensioned cases are heavily strained on firing, and no wonder that if they are then reformed in dies which are probably also made to minimum dimensions (so that resized cases fit all possible rifles) and fired again that they will not last long.

In the end, it all comes down to the only sensible practise for old service rifles, where specifications are hazy or non-existent, and rigid compliance with those specs is also questionable after a century of use - after first firing, only use neck sizing, and only use those cases in the same rifle in which they were first fired. For anyone firing original BPCRs (one of my favorite activities), where the cases cost several dollars or euros each, this is so obvious that it need not be discussed.

So I advise everybody to stop worrying about specifications of arguable origin, validity and applicability, and simply form their real brass to fit their real rifles, not theoretical values. I am intrigued by the theory and the engineering problems that have been thrown up in this thread, but I also want to shoot my rifles!

Patrick

-

-

Legacy Member

Patrick,

Many BPCRs (and all those I shoot) have little to no effective shoulder.

The 45-70 is one that I have fired thousands of rounds through using relatively few cases. I have never had a case head separate on a BPCR. I have had them burn through with a pin hole and have had the necks split.

BTW the bullets are always lubed with lots of gooey lube and at times it gets all over the cases and chambers with no ill affects using smokeless powders.

-

maximum cartridge as standardized to be fired in Lee-Enfield rifles?

PM

PM