-

Legacy Member

No 4 & No5 Bolt Heads (Update)

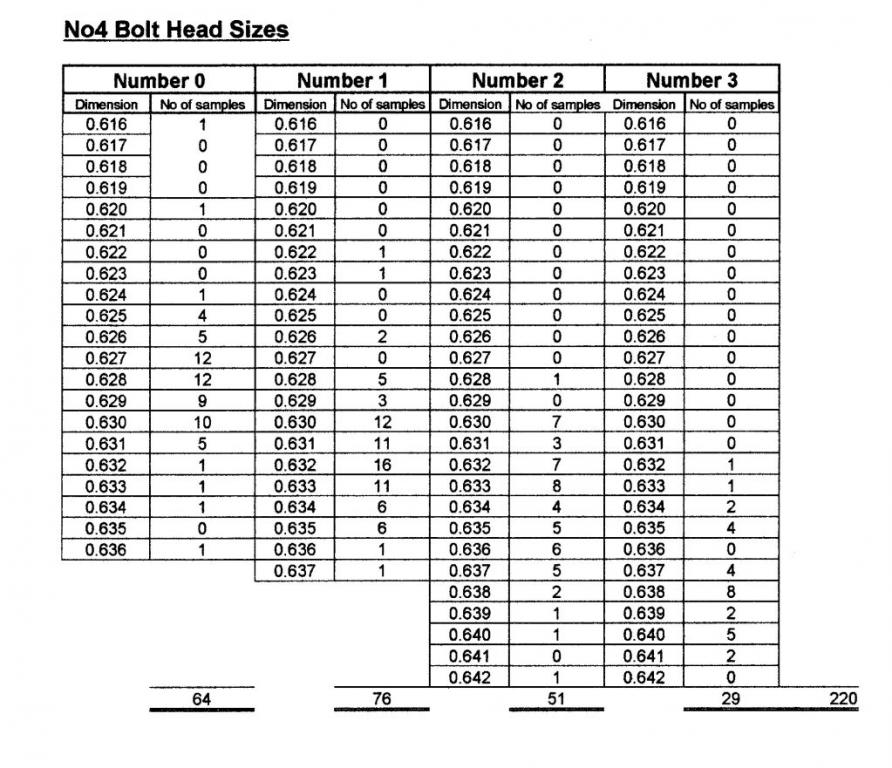

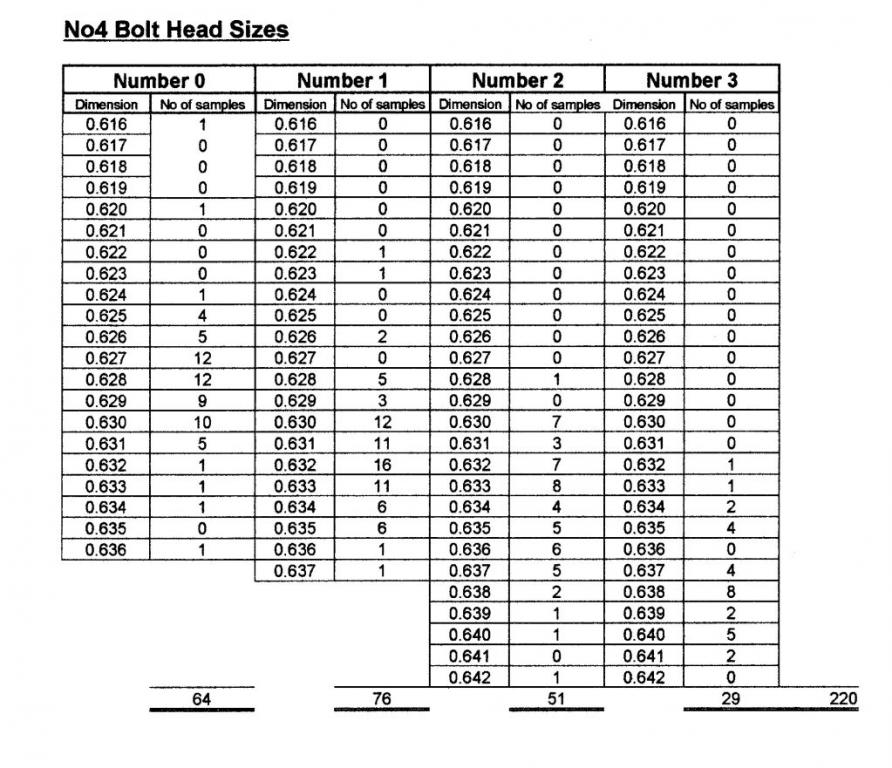

As many of you will remember I have been compiling a spreadsheet of bolt head sizes for a few years now, and, now having the dimensions for 220 bolt heads I thought it was time for an update.

As you will see (and has been stated on numerous occasions) it is no use at all simply saying "I need a Number 3 bolt head" when (for example) a 0.632" up to 0.636" bolt head can be a number 0, a number 1, a number 2 or a number 3.

Tradition has it that the bolt head "numbers" fall within the following dimensions :

0 - .620 to .625 in.

1 - .625 to .630 in.

2 - .630 to .635 in.

3 - .635 to .640 in.

I hope you can see from the spreadsheet that this is not necessarily correct.

Note : I use the term "NUMBER" and not "SIZE".

Disclaimer - these bolt heads have been measured by several people using different measuring 'tools'. There is no way that these statistics would be taken as 'accurate' for QC purposes but I believe they show enough guidelines for us to be very careful when we are buying a 'new' bolt head.

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

Mine are not the best, but they are not too bad. I can think of lots of Enfields I'd rather have but instead of constantly striving for more, sometimes it's good to be satisfied with what one has...

-

The Following 13 Members Say Thank You to Alan de Enfield For This Useful Post:

5thBatt,

Beerhunter,

Brian Dick,

Clash77,

crusty,

jmoore,

paulseamus,

Peter Laidler,

Ridolpho,

sean1960,

Simon P,

Steve H. in N.Y.,

stitch303

-

02-07-2012 04:09 PM

# ADS

Friends and Sponsors

-

FREE MEMBER

NO Posting or PM's Allowed

This information is more helpful than a door jam for an itchy back.

The problem I have run into more than a few times is #1, #2, & #3 heads are hard to come by and when you do find them, there are no measurements provided.

-

Like I've said many, many times on this very forum, a bolt head NUMBER iosn't really indicative of a size but an estimation....... Many's the time a bolt with a size, say, 1 bolthead is undersize for CHS so you'd automatically try a size 2. But while this is how it SHOULD wotk, it doesn't necessarily. Try a few more size 1's or even a few size 0's and you'll find a few in the tray that will correct it. Obviously we had a big binfull of crack and hardness tested bolt heads.

Another word of warning too........... Don't forget that changing a bolthead will also alter various other important features of a previously perfect bolt - such as overturn, lift, FPP as well as CHS

-

Thank You to Peter Laidler For This Useful Post:

-

Don't forget that changing a bolthead will also alter various other important features of a previously perfect bolt - such as overturn

I'm wondering if overturn (i.e. bolt head rear face wear) would account for some of the variations in nominal size.

Excessive overturn seems a more serious condition than a few thousanths more headspace.

-

-

Legacy Member

Originally Posted by

jmoore

I'm wondering if overturn (i.e. bolt head rear face wear) would account for some of the variations in nominal size.

Excessive overturn seems a more serious condition than a few thousanths more headspace.

From my limited knowledge 'bolt head overturn' will in fact lead to increased headspace as the 'threads' on the bolt head / bolt body take the hammering of the recoil (and compress) rather that the two flat surfaces of the bolt head and bolt body taking the load and passing it back down the bolt body to the locking lugs.

With regard to "rear face wear" I would have expected that to make the bolt head 'shorter' whilst most of those measured tend to be longer that the expected norm.

I can find no references to actual bolt head size in any of the 'official' books / booklets I have, all I have found (example "Parts Identification List" dated 1945) is that "No1 to No3 increase in length by increments of 0.003"" but no starting size is quoted.

Last edited by Alan de Enfield; 02-08-2012 at 06:01 AM.

Mine are not the best, but they are not too bad. I can think of lots of Enfields I'd rather have but instead of constantly striving for more, sometimes it's good to be satisfied with what one has...

-

Thank You to Alan de Enfield For This Useful Post:

-

The PLAN size of the length of the bolt heads are

No3 - 0.638" -.002"

No2 0.635" -.002"

No1 0.632" -.002"

No0 0.629" -.002"

You can see that even from this, if a, say, size 3 is made to the drawing spec, then it COULD easily be 0.636". As I said, we didn't take much notice of the number but might use it as a bit of a rule of thumb guide. Same as Bren or L1A1 locking shoulders

-

The Following 2 Members Say Thank You to Peter Laidler For This Useful Post:

-

Legacy Member

The PLAN size of the length of the bolt heads are

No3 - 0.638" -.002"

No2 0.635" -.002"

No1 0.632" -.002"

No0 0.629" -.002"

That makes sense -there are 'clusters' around those dimensions.

I just wonder if some manufacturers (maybe Non-UK ones for example) had a slightly different 'start point' or worked to bigger tolerances or +/- tolerances.

Is there a date on the document from which you have sourced this information, would it be possible that prior to this date there was a different specification ?

Any suggestions why else there is such a wide disparity ?

Mine are not the best, but they are not too bad. I can think of lots of Enfields I'd rather have but instead of constantly striving for more, sometimes it's good to be satisfied with what one has...

-

-

Advisory Panel

Originally Posted by

Alan de Enfield

Any suggestions why else there is such a wide disparity ?

`

Probably because the disparity in size actually helps fulfil the requirement - i.e. an armourer rummaging through his box of spares is likely to find a bolt head to fit without having to make any adjustments. I would not be at all surprised if this dimensional control was deliberately relaxed for this very reason; after all - other components are remarkably consistent between manufacturers and years and models - eg sears, triggers, pins and the corresponding dimensions of the action bodies.

I guess the minimum number of rifles any armourer would be responsible for would be about 100 (ie a company or other sub-unit). Probably even at this level, the armourer would have thirty to fifty boltheads in his spares pack (there is probably a scaling document somewhere). I suppose I have about a hundred No4 boltheads, and find that I can get a perfect fit by trying about 15 to 20 (and I can even usually match the manufacturer as well in that size sample).

-

-

Originally Posted by

Alan de Enfield

From my limited knowledge 'bolt head overturn' will in fact lead to increased headspace as the 'threads' on the bolt head / bolt body take the hammering of the recoil (and compress) rather that the two flat surfaces of the bolt head and bolt body taking the load and passing it back down the bolt body to the locking lugs.

With regard to "rear face wear" I would have expected that to make the bolt head 'shorter' whilst most of those measured tend to be longer that the expected norm.

Odd, that. Contrary to expectations!

-

-

This thread and the findings should be compulsory reading for every gunsmith, Enfield enthusiast and home tinkerer.

Well done all concerned especially AdeE.

-

Thank You to Peter Laidler For This Useful Post:

Information

Information

PM

PM