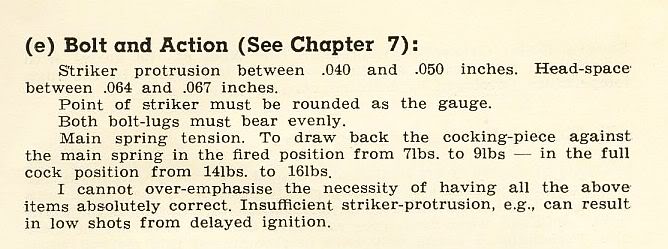

If you handload for a .303 with generous headspace, there's often no need to mess with

bolt heads - changing the rifle's clearances to yield longer case life. You can control cartridge end-play simply by changing technique.

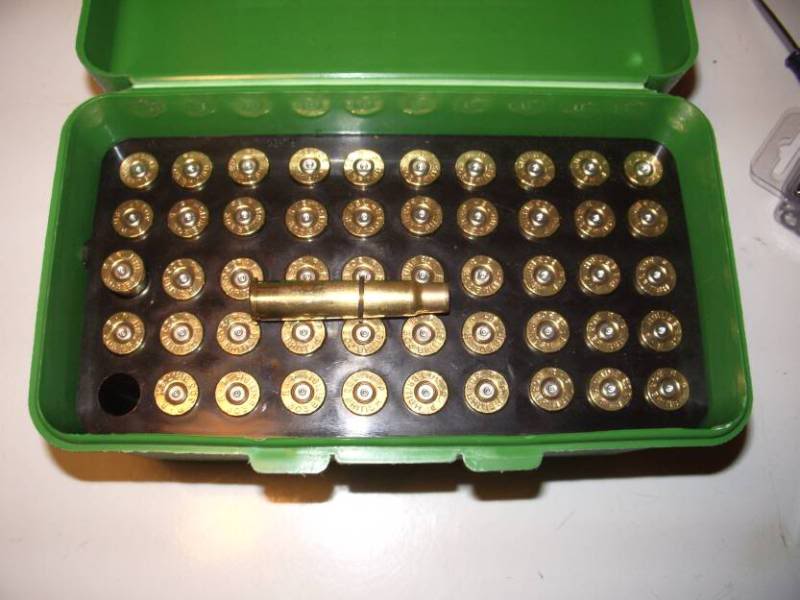

When you fire a

new case for the

first time, use an improvised spacer ahead of the rim - anything from a precision metal washer to dental floss can work to hold the the cartridge

head firmly against the

bolt face and eliminate or reduce stretch even if end-play without the spacer would be significant. Another way of accomplishing the same end is to use a bullet seated out far enough to jam into the lands, "headspacing" on the bullet instead of the case. Such techniques are useful

only if the rifle has excess headspace (or cartridges have abnormally thin rims). With normal headspace and cartridges, initial stretch isn't enough to worry much about.

O-rings are a slightly more costly spacer material preferred by some.

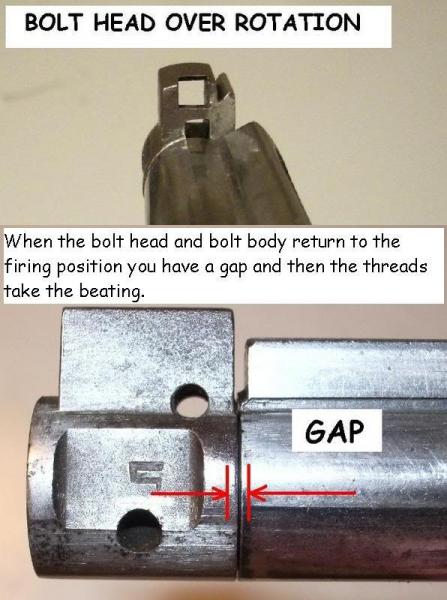

After you've fire-formed your new cases they will fill the chamber fully, stopping on the shoulder just like a rimless cartridge. If you neck size, you'll have zero "headspace". If you have to full length size, adjust the die so the cases chamber with just a bit of resistance in the last few degrees of

bolt rotation. The result, if combined with reasonable-pressure loads, can be extended case life despite generous headspace.

PM

PM