-

Legacy Member

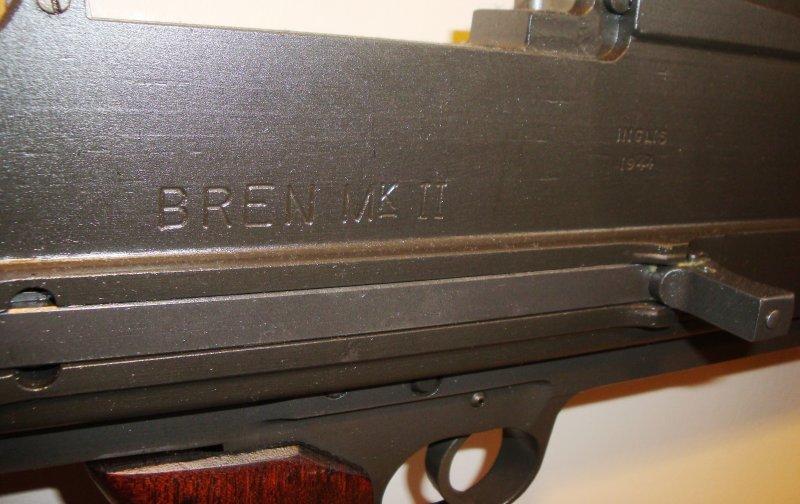

What is the proper finish on a 1944 Inglis?

I have have a reweld semi and tried parking it. Turned out grey for some reason and shows my welds, yuck! Were the the Inglis finished with a Suncrite type finish?

Ignore the date, its a 43'

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

Thank You to c310pilot For This Useful Post:

-

12-01-2010 07:22 PM

# ADS

Friends and Sponsors

-

Legacy Member

Yes, a sand & water blasting (Combined together method) to remove all old paint, rust Etc. & leave a lovely SMOOTH finish. The Phosphating (Parkerising) SPRAYED with Suncorite Black Paint (Mask the gas cyliner though,that was NOT painted) & baked in an oven for 30 Minuites & finally oil dipped & left to drip dry (As far as it could!) & reassembled. Suncorite USED to be manufactured by Henkel Chemicals, though I hear they no loner exist. I cannot confirm that at this time. The paint is heat resisiant & was originally developed for spraying on car radiator cores. It si VERY good stuff, though BEWARE! ONY use in VERY well ventilated areas! It is VERY toxic to inhale!

-

-

-

I think that they were originally phosphated. It's the phosophate that is the rustproofing but the paint protects it. As Tankie says, it is very tough and hardy paint. A man from ATO (the original makers before Henkel and Tri-Mite) told me that it was a government formula for the Ministry of Supply in the 40's so presumably the Ordnance factories. I don't think I'd use it on a radiator though becausethe baking temp is just below the putty stage point of solder

Are the two pics on the left 'as phosphated'? The pics on the right 'as bead blasted'?

I bead blasted, phosphated and painted all of the bumper irons, front sub frame and suspension plus a zillion bits underneath and in the engine bay of my MGB GT V8 when I was restoring it. Yes, tough paint indeed. Tankie is right though, it's now very hard to get and there's no stock available at the moment from either Tri-Mite or Henkel

-

-

Legacy Member

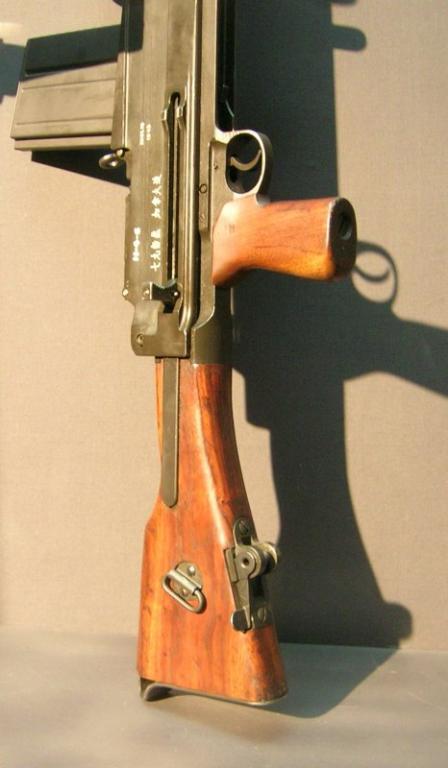

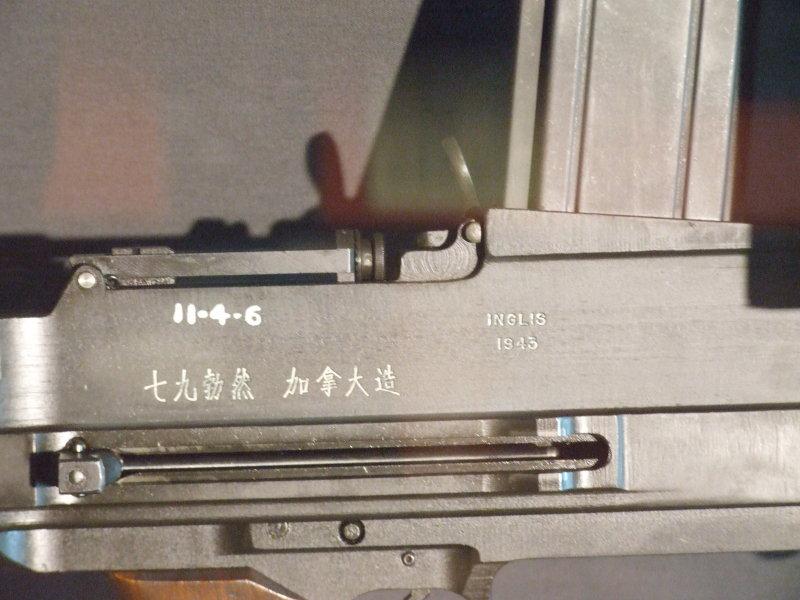

Here's a close up of the finish on my 1943 Inglis MkII:

It looks old, although as to whether it's the original factory finish..?

Mark

Nature and nature's laws lay hid in night;

God said "Let Newton be!" and all was light.

-

-

Legacy Member

That looks the original finish to me. I've one of the very last Inglis Mk2s in a near mint condition and the finish is the same.

-

-

Legacy Member

I don't think I'd use it on a radiator though becausethe baking temp is just below the putty stage point of solder

Peter, we have both encoutered this wonderfull paint of course in Service. The only reason I discovered that it was also used in the Radiator repair side of things is as follows.

I was a restoring a Ferret scout car I owned about 14 years back. One of the problems was with re-occuring fuel blockages & crap getting into the carb. I needed to remove the fuel tank (Not easy with the Turret still on it!) & take it to a place in Hove who did brake re-linings & Fuel tank repairs. They had to flush out the tank to kill ANY vestigaes of fuel fumes. Then cut three square patches in the tank & peelback. THOUGHROUGHLY clean the tank inside & weld up the patches & pressure test for any leaks. Cured the probelm fantatstically! Whilst there, I smelt this VERY familiar smell of the old Suncorite paint & enquired what it was they were using.

Yep, it WAS Suncorite. And the chap explained that they used it because of it's heat resisting properties. After all The cores & gills of a Rad have air passing through them all the time & keep the Temp down in that area well. (Modern Rads are actually NYLON, would you believe! ) I have also had Motor cycle silencers done when I was at 27 Command Wksps with excellent results. It may vary form batch to batch, & obviously any item that runs VERY hot will soon lift the paint! Pete, you werent using it on pot bellied stoves in the Wksp, were you?...................LOL!

But you know how it is..............Ill just bung it thorough the system!.............................

-

-

Sunkorite was also available under the name RILPRIM. It was used as a sort of primer underneath a nylon coating process call RILSANISATION. I'll check out with thge equipment manager what is happening to the process now that sunkorite is in short supply.

While talking of repairing/welding fuel tanks, I watched someone reweld a dribbly seam on my old 750 Norton Commando tank by putting a hose from an exhaust pipe into the filler and letting it vent via the other orifices. It's inflammable and while he had the exhaust gas running through he migged up the seam perfectly with no sign or hint of anything untoward.

-

-

Legacy Member

I think that they were originally phosphated. It's the phosophate that is the rustproofing but the paint protects it. As Tankie says, it is very tough and hardy paint. A man from ATO (the original makers before Henkel and Tri-Mite) told me that it was a government formula for the Ministry of Supply in the 40's so presumably the Ordnance factories. I don't think I'd use it on a radiator though becausethe baking temp is just below the putty stage point of solder

Are the two pics on the left 'as phosphated'? The pics on the right 'as bead blasted'?

I bead blasted, phosphated and painted all of the bumper irons, front sub frame and suspension plus a zillion bits underneath and in the engine bay of my MGB GT V8 when I was restoring it. Yes, tough paint indeed. Tankie is right though, it's now very hard to get and there's no stock available at the moment from either Tri-Mite or Henkel

That is correct. Peregrins - would you say thats a paint type finish? Seems a bit glossy for just park.

-

-

Legacy Member

Nature and nature's laws lay hid in night;

God said "Let Newton be!" and all was light.

-

-

FREE MEMBER

NO Posting or PM's Allowed

PM

PM